Advanced Manufacturing and Design Technology (AMDT) student Blake Davis programs a Haas CNC lathe. Photo Credit, all images: Central Community College

How would you describe the Advanced Manufacturing Design Technology (AMDT) program at Central Community College in one sentence?

Bruce Bartos, AMDT Instructor: We allow students to start with a concept and follow through to the finished part and everything in between. That’s our hook.

Alison Feeney, Associate Dean of Skilled and Technical Sciences, Skilled and Technical Sciences Department: You walk into our lab space, and it’s a wow factor with the instructors and technology. It gives you chills.

Bruce Bartos, AMDT instructor (left), explains the workings of the Milacron injection molding press to students Harrison Ottens (center) and Gunner Fischer (right).

Share a little history about this program.

Troy Davis, AMDT Instructor: We are in the heartland. Hastings, Nebraska, has an amazing pocket of tool shops that support the automotive, medical, aerospace and defense industries.

Drafting and design instructor Gene Friesen assists student Dakota Sell with the design of an injection mold insert to be produced with a Desktop Metal system.

In 1972, Central Community College (CCC) got its first injection molding press and a small stamp press until about 2008. After that, the college wrote a workforce training grant, was awarded the grant money and created the Center for Plastics and Design. Then in the fall of 2009, we started to invest using the $2.1 million grant funds.

We started with a donated 110-ton Arburg injection molding press from Becton Dickinson (BD) and I was hired as an instructor. BD has been instrumental in helping to develop the AMDT program’s curriculum in addition to their equipment donations.

AM-produced projects in the foreground. Stratasys, Desktop Metal, Flashforge and Formlabs 3D printers are in the background.

AMDT student Shane Seim works on a probing calibration exercise inside a Haas vertical machine center.

What is the overall mission of the AMDT program?

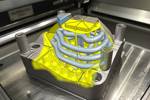

Bartos: Basically, a student starts from a concept or an idea, then designs the part. We then review it, run it in our plastic or metal 3D printer to look and touch the part to verify the design. If the design is good, we move onto mold design. Then we run it in our injection molding presses. The students get the whole learning experience, so nothing surprises them when they get out in the industry.

Arburg molding press (left) and Milacron injection molding press (right).

Break down your arsenal of technology.

Bartos: Most of our equipment purchases are based on supplier relationships. For example, we have 26 Haas spindles because they not only support us with equipment but also offer scholarships. Here is a breakdown of the AMDT lab equipment:

- Twenty six Haas CNC spindles

- Makino EDMs—U3 Wire and EDNC2 sinker

- Arburg 110-ton molding press

- Milacron Roboshot 100-ton molding press

- Belmont hole popper

- Beckwood 45-ton stamping press with coil feed system

- Master3DGage

- Zeiss Duramax CMM

- Six Lagun manual milling machines

- Six Sharp manual lathes

- Six Acer surface grinders

- Wazer water jet

- BOSS laser

- EZ set tool presetter

- Cosen saw

- Cress heat treat oven

- Desktop Metal BMD studio system (17-4PH Stainless Steel)

- Stratasys F370 FDM (ASA, ABS, TP)

- Flashforge Desktop FDM (PLA)

- Formlabs 2 SLA (Photopolymer Resin)

Drafting and design student Dakota Sell standing in front of the Desktop Metal debinder. The Desktop Metal furnace is just to the right.

We try to stay ahead of technology. We want to keep surprising our students and that’s where our advisory board comes in. Our next piece of new technology is robotics. We’re going to try and fit it in with our desktop mill in our Futures Room, which highlights non-traditional or fringe technology such as a CNC laser table, CNC waterjet, metal 3D printer, desktop mill and robot and a virtual welding simulator.

What is the CCC AMDT advisory board?

Troy Davis: Our advisory board comprises local manufacturers in our service area for the college. They are business owners, business reps, folks in the tool shop, toolroom managers, etc. They guide our curriculum. We take tours of their facilities with the students and they visit the school to promote manufacturing and their companies.

The advisory board helps us get out into the industry to learn what’s going on, what technology is being used and how to teach our students better. Then we jump ahead and budget for the necessary equipment.

Board members run three-year terms, but they are welcome to stay on and rotate within their organizations. We have the largest (or second largest) advisory board on campus with 38 members.

We hold at least one formal meeting a year and meet informally all the time. Informal meetings occur within our Manufacturing Pathway Advisory Team (MPAT) meetings that are held once a month.

The MPAT began several years ago with members from CCC, Hastings public schools, the local chamber of commerce and local business and industry partners. We hold annual meet-and-greets that connect industry and education. Our local manufacturers have outstanding careers within their organizations, so we find creative ways of bridging the gap between local industry and students. All members support SkillsUSA chapters at the high school and post-secondary levels. These local manufacturers also give us a call when they are looking for people.

What’s the most successful advisory board suggestion?

Brian Davis, Instructor, AMDT: The new building design. They had a guiding hand in what the facility would look like, respecting that the college wanted continuity with the existing structure. Having them involved changed the whole concept of the building that the college was initially looking to create. Their input was invaluable to the shop layout.

It started as a remodel, but we went from a 6,800-square-foot lab in the old building to 17,000 square feet. It’s because of our advisory board… and we did this in one year!

Initially, everyone assumed it would take 18 months to two years just to get the money to support this expansion, but the response from the advisory board to add on for this program was so overwhelming; we had the money in six months!

Bruce Bartos, AMDT instructor (left), conducts a part inspection with student Gunner Fischer (right).

How many students are currently in the program?

Brian Davis: We have 48 students. Our AMDT program has had students from surrounding states, including Colorado, Iowa and South Dakota. We had one graduate from the Netherlands and currently have a student from Canada in our program. Most of our students are in-state and our CCC service area. We have on-campus rooms for 350 students in our dorms.

Bartos: In 2008, when I started, we had two part-time students. Then in 2009, when Troy came aboard, we jumped to 20, as the economy turned around and there was a lot of retraining. Then we got the grant and the program exploded from there. In 2017-2018 we leveled off because we were out of space. Our numbers dipped because of COVID-19, but they are coming back now.

What are CCC AMDT’s recruitment efforts?

Bartos: We talk to everybody. We do a lot of the career fairs talking to 200-300 high schools kids. I have to say we’re pretty good salesman. We love to talk about what we do because everybody’s so excited about it. We just love what we do.

Our industry partners are committed to helping these kids finish college instead of hiring them right out of high school. They offer support through scholarships.

Troy Davis: We have constant tours on campus from our admissions department. They love to bring them through because we give away plastic parts. We also have Pathway Partners that serve as feeder schools. We have Hastings High School, Career Pathway Institute in Grand Island and Sandy Creek. These programs allow students to take our first semester courses in high school. So they’re basically coming to us in the second semester.

Brian Davis: We also know many industry people who recruit for us when they know companies that are hiring.

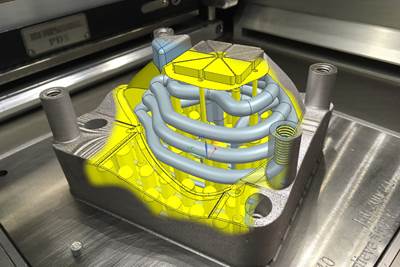

Injection mold insert produced with desktop metal system.

What makes this industry/academia relationship unique?

Feeney: It’s a Midwestern thing—they don’t want to steal our students. They understand the importance of our program and our degrees and they are not out to undercut us at all. That is because of our working relationship between the instructors, the college and our stellar facilities.

They understand the importance of that degree and those two years to get their hands on all the equipment. They know the value of being patient and waiting for those students. They know that it’s going to be worth it in the long run. So they’ll hire them part-time and then sit tight with them until they graduate.

How would you define this generation and how does your program change them?

Bartos: They come in as kids and two years later, they have confidence, maturity and excitement about starting their careers. They struggle the most with math skills, excel at using computers and creativity and have the most fun on the CNC equipment. We should also note they walk away with the soft skills they need to succeed in the industry.

Troy Davis: We have a class that starts at 8 o’clock, but I say to them, “8 a.m. is late. You have to be here before that.” We are very rigid on all the work ethic responsibilities.

AMDT student Stefany Chavez Gomez programs a Haas CNC lathe.

What is the moldmaking portion of the curriculum?

Bartos: Students learn how to polish, make a simple mold cavity and perform mold repair. Then they move onto basic part design (draft, sink), and run the program on the 3D printer to ensure that part is meeting expectations and requirements. It’s a process. We meet every morning for 15 minutes to review problems and come up with solutions together. We don’t just turn them loose and say, “Go build.” Instead, we thrive on allowing them to make mistakes.

Troy Davis: The final part is gathering around the molding machine to see their part come out of the press. It is a thrill for us and the students are so proud! They run around the shop showing everyone.

Brian Davis: We assume everyone starts at zero whether you have experience or not. So, when they come into our program, they begin with the manual machine. Plus, our advisory board wants fundamentals. We teach the basics of facing, milling, counterboring, drilling, holes, etc. We go through all feeds and speeds. This is the foundation we build everything on.

The first semester is manual machining and introduction to CNC with a focus on the controller. At three weeks, they make a part—they program and run a simple part to see how the machine works. The second semester is eight weeks of manual, then eight weeks on the CNC lathe, including Mastercam and Solidworks classes. Next is learning to code to make the machines fly.

Overall, thefirst year is a learning process—how to operate everything and get everything under control.

The third semester is all moldmaking. First, students take their part design and build and run a mold. Then the final 16 weeks, the fourth semester, is die design and construction and advanced machining, probing, four- and five-axis machining. On the processing side, we have an Arburg 110-ton molding press and an all-electric Milacron 100-ton press.

After students earn their two-year associate’s degree in AMDT, they spend one more year earning a two-year Drafting and Design (DSGN) associate’s degree. DSGN allows up to 18 credits (six classes) from AMDT to fulfill elective requirements. Plus, 15 credits from General Education courses.

The extensive background of the AMDT students who enter the DSGN program enables them to take on challenges a typical two-year DSGN student could not. For example, working with our Desktop Metal 3D printer. Students with a degree in plastic injection molding design and build mold inserts with the metal 3D printer.

What is a key takeaway about the CCC AMDT program?

Bartos: We want people to know that we are here, first and foremost, and not a one-trick pony. Students can go in so many directions through this program. You don’t have to do only one thing. It’s the start of a career with unlimited possibilities.

Related Content

Next-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreGrowth Requires Mold Builder/Molder to Shift Tooling Focus to Maintenance, Repair and Replacement

The results of aligning awareness and acceptance across departments to balance new tooling and quick response needs.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreRead Next

Thermoset Mold Builder Takes on EV Market

New Dynamics and NDC International provide complete tooling and molding solutions for the electric vehicle market and electronic encapsulation technology.

Read MoreNew Ownership Revitalizes Precision Mold Builder with Heavy Capital Investments, New Management Style

A rich history in mold building, recent technology investment and a shift in management philosophy re-energizes a Midwest precision mold builder and contract CNC machine shop.

Read MoreGrowing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

Read More