Project-Based Learning – The Rest of the Story

In this month’s issue of MMT, I wrote about an instructor’s strategy for teaching his mechanical engineering students about moldmaking via project-based learning. I couldn’t include absolutely everything this instructor teaches his students, so I thought I’d blog about it.

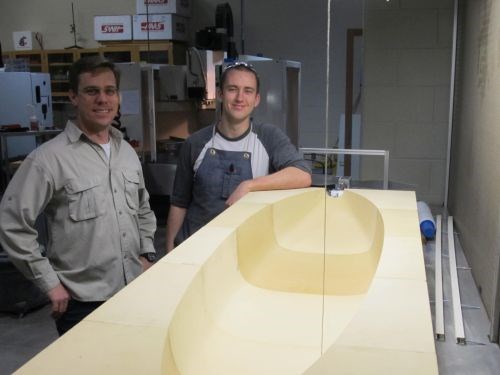

WSU Students used Mastercam software to build the fuselage for a hydrogen-powered UAV. Because the part was so big it needed to be machined in sections and then assembled later.

In this month’s issue of MMT, I wrote about a Washington State University (WSU) instructor’s strategy for teaching his mechanical engineering students about moldmaking via a project-based approach (See “Project-Based Learning”). I couldn’t include absolutely everything this instructor, Kurt Hutchinson, teaches his students, so I thought I’d blog about it to show readers how his students prove out what they’ve learned under his guidance in his Cougar Lab classroom.

Hutchinson says the mechanical engineering students at WSU often get involved in clubs within The American Society of Mechanical Engineers (ASME). A couple of these include Formula SAE (race cars) and the American Institute for Aeronautics and Aerospace (AIAA) club. According to Hutchinson, club activity intensifies prior to competition time (There are always competitions and what better way to prove out skills while having some fun?). Following is a section that didn’t make it into the printed feature article that shows examples of how the students employed Mastercam software to program toolpaths for milling the components used in competitions.

Hutchinson is the advisor for the Formula SAE team that builds a small-scale open-wheel racecar for its annual competition. A wide variety of pieces need to be machined, including mold making, all made easier with the use of Mastercam X9 software. Some students are using Solidworks to develop designs for parts for machining. The challenge for students is to design a car that is as lightweight as possible, using as many composite materials as they can for the body of the car. “This year we used high-density urethane modeling foam to create molds that they can vacuum bag composites into,” Hutchinson says. “We did a mold for a seat, a body panel, and an intake plenum for the engine.” Typically, the students would be required to mold carbon fiber prepreg, wet layup, and vacuum the composites into the mold. Styrofoam, while lightweight, cannot be used because the vacuum bagging process can crush a mold that is not high enough in density to withstand the process without deforming. In addition, these molds must often be autoclaved and materials need to be able to withstand high temperatures. High-temperature materials go hand-in-hand with aerospace applications and the Cougar Lab is no stranger to that type of high-end machine work.

The AIAA club builds a hydrogen-powered UAV for its annual competitions. Hutchinson built molds for the club in 1997-2012 and keeps them on-hand for instructional purposes. Two years ago, one researcher was awarded a grant to build a hydrogen-powered UAV and the club turned to the lab for help. Hutchinson and his students – one of whom was an AIAA member – built the mold for the fuselage, which measured six-feet long. The crew used Mastercam to machine the large pill-shaped part in pieces that were small enough to fit inside the vertical machining center. They then slid together like a big Lego. The mold looks sort of like a bathtub with a gel coat on the inside. The team used it to layup the fuselage for the aircraft, which has flown several times. The students were also asked to build the end enclosures for a cryogenic chamber using projected toolpaths. “There was some really sophisticated, dynamic high-speed milling being done on the pockets,” Hutchinson notes.

While the “moldmaking” discussed here isn’t the kind our industry practices, using CAM software to program high-speed milling programs is a skill that crosses disciplines. Add to that the need for precision and design aptitude, and I think it’s safe to say that Hutchinson’s students are in solid contention for jobs in advanced manufacturing no matter what sector of the industry they decide to pursue. Here’s to educators like Hutchinson who work so hard to make it real for their students through project-based learning.

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More