Advanced Software Features Latest Functionalities to Improve Productivity Tools Critical for Moldmaking

CNC Software says IMTS 2022 attendees will experience the latest multiaxis, mill-turn features and enhancements of Mastercam 2023 driven by industry feedback.

Attendees at the IMTS 2022 are said to be experiencing the most powerful machining software from CNC Software LLC to date, Mastercam 2023. Visitors can investigate the latest functionality of Mastercam, many of which are geared toward mold builders, at booth #133222 and at the Student Summit booth #215200. The software will also be on display throughout the IMTS show floor, with over 40 parts being programmed in Mastercam partner booths such as MC Machinery ($338129), Okuma (#338500), DN Solutions (#338900), and Fanuc (#338919).

Meanwhile, in the main Mastercam booth, Mastercam partners, resellers and employees will be giving presentations every hour Monday-Friday on many different topics and features. Stas Mylek, partnerships program manager at Mastercam, will be presenting “Digitalization of the Manufacturing Floor: Are SMEs Ready for the Next Wave?” on Monday, September 12, from 3:15 – 4:10 p.m. in room W192-C. He will cover how emerging digitalization will impact small and medium machine shops, and how best to prepare for change.

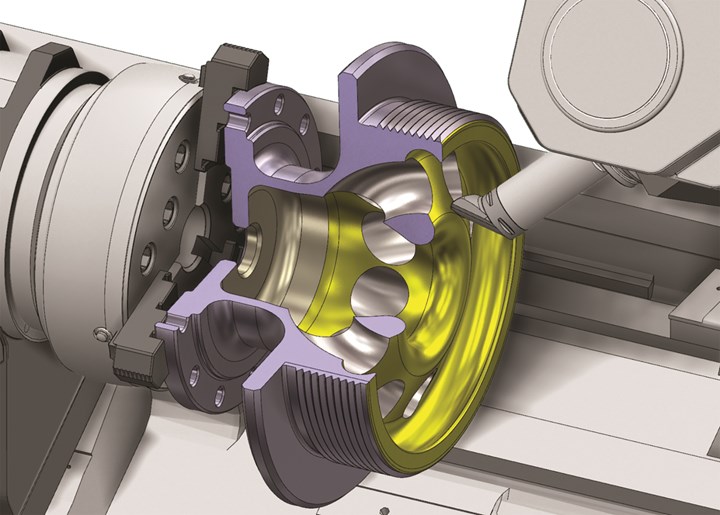

CNC Software notes that it is spotlighting a variety of Mastercam software features that are especially powerful for mold builders. Among them is Mastercam’s Accelerated Finishing which is said to deliver precision control of today’s new-shaped tools. For suitable portions of molds, this technique delivers both faster machining and an optimized final finish. Mastercam also has a specialty CAD toolset and options that are geared toward the single most important application a mold shop faces — getting molds and mold bases on and off the machine with speed and precision. To top it off, streamlined model prep, setup and NC programming offered by the software is said to decrease the time it takes to get mold components on the machine, and stock-aware toolpaths and optimized motion deliver reduced cutting time and ensure high-precision finishes, all in the name of higher productivity.

Additional features and enhancements to be highlighted include consolidating multiaxis toolpaths to allow access to Morph, Parallel, Along Curve and Project Curve cut patterns when adding the appropriate curves; detecting undercut stock when machining via the Dynamic OptiRough and Area Roughing toolpaths; and introduction of a new B-axis contour turning toolpath that allows for rotation of the B-axis while the tool is cutting.

Related Content

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.