Moving Moldmaking Forward with Dynamic Toolpaths

It's not a matter of how much equipment or manpower you have. What is more important is how well you use what you've got.

A small start-up tool & die shop in Crothersville, IN, is thriving because of its ability to do high quality mold design and manufacturing while producing more than companies many times larger. TyMar Tool Works attributes this significant boost in productivity to its extensive use of Mastercam’s dynamic toolpaths, which operate at high throughputs while minimizing tool breakage so that machines can run unattended.

The high reliability of these toolpaths allows shop owner Mark Emly and his assistant to spend almost all of their time doing work other than machine operation. This includes quoting, design, tool assembly and product delivery—all things that keep the business moving forward. This unique style of operation is the product of the owner’s long-held conviction that he would do things differently when he got to be in charge.

Built from Scratch

One evening 20 years ago, when Emly was a young machine operator, his boss told him something that would stay with him for the rest of his career: “You are never going to amount to much more than a guy who takes parts on and off machines, on the night shift." That was when Mark made up his mind to learn everything he possibly could about machining and tooling—no matter how long it took, so he could prove his boss wrong and open his own shop.

"So I would work in one place, learn as much as I could and then move on," he say. "I remember sitting in a job interview and telling a guy 'yeah I can do that.' Then it was sink or swim." He gravitated towards "small shops where you learn how to do everything," which for Emly eventually included machine set-up, part inspection, CAD/CAM programming, manufacturing process engineering, and part and mold design.

In 2010, after nearly two decades of hard work and self education, he was ready to start his own business. He supplemented his income to support his family by working a part-time job, while he worked full-time in a shop near his home. This made it possible for him to gradually build up a base of steady customers doing work he enjoyed and was good at.

He notes, "In February of 2012, my own work got too busy, so that seemed like a good time to focus on my own business full time.” By early 2013, he had acquired 16 customers (all by word of mouth), a full-time helper, and enough cash flow to invest in a new Hurco VM20i vertical machining center with a 10,000-rpm spindle.

Different by Design

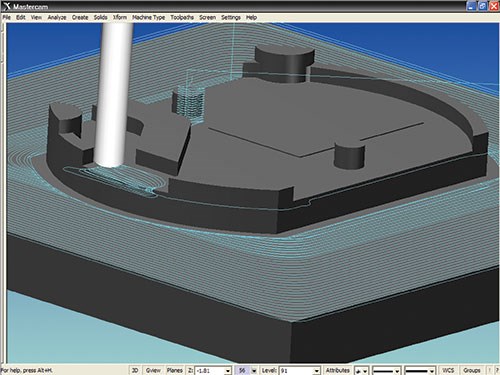

When Emly started his shop, Tymar Tool Works, his decisions were mostly conservative—the shop was on his own property, he did all the work himself and he bought a used Hurco machining center. There was one exception: he purchased Mastercam Mill Level 3 with Solids CAD/CAM software (from CNC Software, Inc., Tolland, CT).

This was a full-blown maintenance license that entitled him to free up-grades and as-needed technical support from his reseller, CAD/CAM Technologies, Inc. (Pendleton, IN).

"I wanted my shop to be different from others I had worked at” he states. “I want to be a small shop with a big presence. That means taking advantage of my design skills, producing high quality parts, and using advanced technology as much as possible so I can compete effectively. The only way I could do that was to have a good CAM system from day one. I chose Mastercam because that was what I'd used at every shop I worked at and was proficient in it."

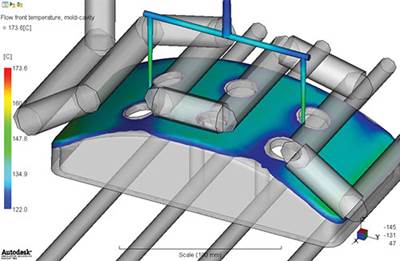

Emly has also purchased a seat of SolidWorks because that is what most of his customers use. A big part of his job to date is designing molds for the RIM (Reaction Injection Molding) process. TyMar Tool Works also has a major customer that makes disposable injection molded guards that protect automotive components during assembly. This business has been very successful and Emly finds himself frequently firing off design modifications to his customer and then manufacturing the final mold configurations on short notice.

One thing that helps him immensely is his ability to visualize manufacturing processes in 3D. Instead of building up molds from 2D components, he designs the mold in 3D using Solids in Mastercam and then spins out the 2D work as needed from the 3D model. Emly believes that process to be much faster, more accurate and less prone to error.

Dynamic Productivity

Although the Hurco machine is in almost continuous operation, neither Emly nor his assistant spend much time operating it. This is because Mastercam's dynamic toolpaths (such as 2D Dynamic Milling and 3D OptiRough) use material awareness algorithms to automatically alter feeds, speeds and entry paths whenever there is a possibility of over-engaging a tool and causing chatter, undue stresses on the part or tool breakage. Because these toolpaths are so reliable, Emly is fully confident that he can run his parts at high throughputs on a lights out basis, and that his work will be waiting for him in the morning.

There are four vises on the table at TyMar Tool Works’ Hurco machining center. During the day, Emly and his assistant load up and work on components that require shorter machine cycles— 15 minutes to several hours. They typically load up the equipment for a last run on the day shift at around 4pm. Emly goes home to spend family time with his wife and children. Early in the evening, sometime around 7pm, he comes back and loads the machine one last time, but this time with workpieces that could take 2 to 8 hours each to machine. He returns home and the equipment runs all night.

Emly shares many other benefits he gets from using Mastercam’s dynamic toolpaths:

◦ Full flute engagement so that more area can be machined, but with less lateral force on the tool.

◦ Lateral force reduction: The material condition aware toolpaths self-adjust to eliminate excessive force on thin walls that might bend and push them in the path of the cutter on the other side.

◦ No broken cutters because the program won't bury the tool.

◦ More secure holding of parts with difficult shapes because the tool won't apply excessive force and snap the part out of the vise.

◦ Optimizing advanced cutter performance by dynamically controlling feeds, speeds and rules of engagement in conformance with the cutters unique characteristics.

Emly is a proponent of choosing the best cutter for the job. “I know some guys who would not spend $45 on a 5/32" carbide drill, but would spend the same amount on a 10-pack of cobalt drills instead. Recently I had to drill 125, 5/32" holes in 5/8" plate. This took me 14 minutes with my carbide drill. It would take the other guys five hours running at 5 inches a minute to drill the same number of holes while breaking all 10 of their drills. My single drill is still in good shape."

He spends a great deal of time talking with his tool suppliers because he knows advanced cutter geometries and materials can dramatically improve his throughput, if the correct toolpaths are chosen. Because these suppliers know that he is looking to push the envelope, they sometimes provide him with new cutter designsm so that he can test them on his applications.

Big Jobs for a Small Company

Early in 2013, one of TyMar Tool Works' RIM mold customers came in with a very big job for the small company—a family of 20 molds, 10 left hand and 10 right hand. Each mold had 10 details that had to be machined before the mold could be assembled. At one point, the Hurco ran for 17 straight days on a 24/7 basis, only stopping occasionally for 15 minutes to have parts taken off and others reloaded. TyMar delivered the molds on schedule in less than seven weeks. In spite of this tight schedule, Emly managed to complete six other projects, some of these also on a short turn basis.

Emly says, "Another customer told me he couldn't believe I made all those molds in seven weeks. A much larger shop did a similar job for him and it took them 10 weeks. They had 15 guys and much more equipment. But it's not a matter of how much equipment or manpower you have. What is more important is how well you use what you've got.”

For More Information:

Tymar Tool Works

(812) 528-2237

toolshop@tymartookworks.com

tymartoolworks.com

Related Content

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

Read MoreCAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreRead Next

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More