2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

Since 1978, Mold-Tech Inc. (Albertville, MN) has zeroed in on manufacturing complex, close tolerance, precision injection molds — specializing in mold types such as multi-cavity, hot runner, auto unscrewing, insert, in-mold decorating, micro, metal injection, silicone, shuttle, and multi-shot, with an average leadtime of six weeks. Strict attention to detail combined with superior customer service while producing close tolerance, precision injection molds has landed the company the 2011 Leadtime Leader Small Shop Award.

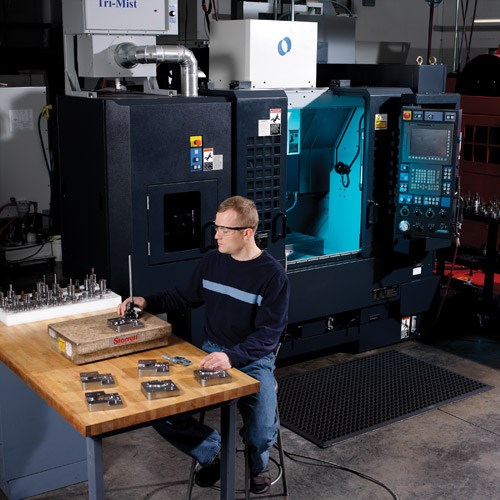

The company primarily serves the medical, electronics, consumer, automotive and telecommunications markets; additional services include custom wire and sinker EDM services as well as high-speed CNC machining, hard milling, end-of-arm tooling and tool tryout/sampling. According to Mold-Tech Marketing Coordinator Rebecca Ford, the key to the company’s success lies in “our highly trained employees who are constantly looking for new technologies and process improvements to aid in the development of high quality molds. Our molds are designed and manufactured to the highest standards. This commitment provides our customers with exceptional value.”

To that end, the company’s business philosophy is to form a partnership with its customers from initial concept and design through final production and delivery. “Our dedicated project managers ensure successful projects by maintaining effective communication throughout the process,” Ford states. “They also build relationships with our customers, so if our contacts migrate to another company, they take us with them.”

Capably Competing

Over the past several years, Mold-Tech has trimmed leadtimes from 12 weeks to 6 weeks (14 to eight for hot runner tools) by employing a number of strategies. “We have added hard milling capabilities, in-house sampling and tool tryout capabilities,” Ford notes. “We continually seek out ways to improve our leadtimes by adding equipment/automation or changing existing processes to incorporate lean manufacturing.”

The company also makes sure that it has the latest in equipment and technology. “We recently purchased and implemented Cimatron manufacturing software to reduce electrode design and programming time, as well as purchased a Makino V22G high speed graphite machining center with 3R automation.” The addition of these items, as well as now having a RJG master molder and a new Toshiba all electric molding machine for tool tryouts, has further advanced the companies capabilities and value to the company’s core customers.

It is vital that Mold-Tech understand its customers’ requirements up front, Ford continues. “We provide tool design concepts with quotations so that when we get a project, the concept has already been agreed upon — which cuts down on design time,” she notes. “We have a flexible work crew and we also run unattended machining. Job control is maintained through weekly staff meetings and progress reports to track project progress.

Industry Immersion

Mold-Tech also prides itself on attracting young people to the trade. “We work closely with the local tech schools (Alexandria Technical and Community College) and high school (St. Michael-Albertville High),” Ford notes. “Our goal in getting involved early at the high school level is to promote machine tool technology as a good career path and to help eliminate the outdated image of manufacturing as merely assembly-line type work. We would like to help strengthen enrollment in the technical programs at the high school.

“We decided to get involved with Alexandria Technical and Community College to give support to staff and offer students exposure to moldmaking as a career choice,” she continues. “Mold-Tech has hosted several plant tours for the Machine Tool Technology Program — giving students a first-hand look at modern machine tools in the moldmaking industry. We have hired several graduates from Alexandria Technical and consider it a great networking opportunity.” The company also serves on the advisory team for the shop of St. Michael-Albertville High School and the advisory board for Alexandria Technical and Community College.

Continuous Improvement

When it comes to future plans, Mold-Tech embraces a continuous improvement philosophy. “We plan on adding more automation to increase productivity and shorten leadtimes, establishing more competitive pricing, and offering more technical training for new equipment and processes,” Ford says. Mold-Tech also plans to target medical OEMs by identifying those companies who need the type of services we provide and reaching out via our marketing and extensive tradeshow exhibitions. It has been proven that if Mold-Tech is given the opportunity to work with a new customer on a program, it will lead to a long and mutually beneficial relationship

“We are recognized for providing great customer service and engineering support while delivering a superior tool — on time or early,” Ford concludes “Our employees are always looking for new technologies and process improvements to maintain an edge over the competition. Our on-time delivery rate averages more than 99% and our customers trust that we will meet their delivery requirements and provide great support for the life of their program. Mold-Tech has been ISO 9001 certified since 2000 and puts great effort into an evolving quality system that ensures utilized processes are documented and consistent.”

Related Content

Mold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreRead Next

2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

Read More2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

Read More2011 Leadtime Leader Awards: Large Shop Honorable Mention

MSI Mold Builders: Redefining Mold Manufacturing with Incremental Approval Approach.

Read More