The Art of Design and Machining

The market is ready to explode as vendors introduce enhancements and upgrades to make the designing and machining of molds and mold components easier and more efficient.

The sheer number of CAD/CAM systems on the market today can make choosing a system a major headache. However, there are a number of new mold-specific features to help take the guesswork out of it: automation of specific processes like tooling quotations, electrode design, automatic core/cavity separation and cleanup. These advancements will allow for fewer design changes, less machining time and reduced manpower. Coupled with improvements in data translation and continual innovations/upgrades made by CAD/CAM vendors, the market is poised to explode this year.

Handling the Issues

Jeff Stegemeyer, the general manager of Stellar Mold & Tool Inc. (Galesville, WI) - a plastic injection moldmaker for a variety of industries - would like to see "seamless" translation between CAD systems. "We still fight that problem," he comments. In complete agreement is Lou Vitullo, the engineering manager for Micro Matic Tool Inc. (Youngstown, OH) - a custom injection moldmaker for a number of industries. "The only problem I'm having now is if we have to make a part change and our customers do not have time to make the part change and send us another file. We make the needed changes to the part and then send an IGES file to the customer. Since our customers have a different CAD package, they must update their CAD geometry. This may be as simple as inserting the IGES file I sent to them, or if they must have a fully parametric part, they have to look at what we did, then recreate the changes to their model so it is parametrically constrained."

For Milledgeville, IL-based Carroll Industrial Molds, Inc, which builds cast to size and aluminum molds for the foam industry, challenges lie in imported IGES files. According to President Craig Dusing, these sorts of problems are common among many moldmakers. "Sometimes we receive data or models that are not contiguous, not watertight or there are gaps and little areas of the model that have to be repaired before we can use it to create cutter paths," he states.

So how are moldmakers handling their CAD/CAM issues? Carroll Mold's Dusing finds that sticking with the same software manufacturer helps them stay successful. "We've been with them for 10 years now and they've been very supportive and come out with new versions very regularly," Dusing comments. "The features we see now compared to 10 years ago - you wouldn't even know it was the same program."

Vitullo of Micro Matic Tool recommends trying to recognize who your customers are before you purchase a CAD/CAM system. "If you are consistently getting one type of file, you probably want to get the same station," he says. "But if you are a custom molder like we are, unfortunately you are not big enough to have a couple of seats of everything, especially if you are looking at twenty to thirty thousand dollars for the high-end systems."

High Hopes

There's quite a wish list out there for what could be in CAD/CAM technology. For starters, Stellar Mold's Stegemeyer and Vitullo of Micro Matic Tool would like the technology to be wrapped up neatly in one easy package. "That sure would be great," Vitullo notes. "From what I've seen, companies are either really good at CAM and lacking on the CAD side, or vice versa."

Stegemeyer expands on this notion. "I wish that a CAM system generated a 'perfect' cutter path without human intervention - it seems like the human still needs to perfect things," he states. "I'd like batch electrode programming together and one CAM system that can do it all - high-speed machining, 3-D surface milling and 2-D milling. You still need to machine 2-D pockets and drill holes.

"I personally would like to see a system that would take a part file - with a little input from me - quote the job, design the mold, create all required cutter paths and send out job/set-up sheets for machining," Stegemeyer laughs. "All we would need to do at the end of that week is assemble and ship the completed tool! I can dream, can't I?"

The rest of Stegemeyer's more realistic desires include easier ways to do things, such as making the systems do the work more automatically - not manually - citing examples like creating parting-lines or splitting parts. "Manufacturers say they can do it now, but it seems like the 'human' needs to fix things to get it right," he states.

"Automatic electrode extraction would be nice - just put a box around it and it is ready to machine," Stegemeyer adds. "It also would be nice to be able to offset the surface on an electrode according to the orbit you want and overburn, then actually machine the 'real' surface and not 'lie' about cutter sizes."

Additionally, Stegemeyer would like to see the shop go completely paperless. "I'd like to do everything graphically, with 3-D pictures for design, programming and CNC machine setup," he explains. "The EDM department can pull up a picture with electrodes in place graphically and let them see easily what they're EDM'ing, what the electrode looks like and burning locations. This needs to be done with a system that is very user-friendly, not requiring a ton of training, and economical so that you can afford to put it on a lot of computers spread all throughout the shop floor."

Dusing of Carroll Industrial Molds also wants to automate. "The only thing we have on the table that we would like to bring in-house is some kind of a digitizing system to digitize our castings," he notes. "In our process we hand fit cores and cavities to produce a telescope or a crush-type fit on the cavity and core. If we could digitize our casting and translate that into a cutter path and cut them according to fit for clearance, it would eliminate a tremendous amount of time from our process. Tightening up our casting tolerances is high priority for us and if we could automate the process - that would be great."

Cost is what is holding these three companies back. Unfortunately, CAD/CAM systems are a huge investment and are not to be entered into lightly. "Once you get into a really sophisticated system it costs big money," Vitullo notes. "The problem with us buying a high-end seat right now is, being a custom molder, we receive files in a number of configurations, and it wouldn't make sense to purchase a high-end seat and dedicate one person to that seat."

Something that may make all of these dreams come true and resolve a majority of CAD/CAM issues would be peaceful coexistence amongst the manufacturers. "I wish that competing companies were willing to share their technologies or open their source codes so that somebody could translate directly from one to another," Vitullo says. "Then I could see the 'design intent' my customer had when they designed their part. Second, I could update their CAD files and eliminate the need to have their designers recreate the changes I already made."

CAD/CAM Happenings

When and if the possibility of sharing technology between companies indeed becomes a reality, a number of CAD/CAM manufacturers are already making some major industry advancements and have chosen to share them - and their effect on the design and build process. Additionally, they offer some tips on how moldmakers can better use CAD/CAM technology.

What major advancements do you foresee in CAD/CAM technology this year?

Dan Marinac, VP marketing, Cimatron Technologies (Livonia, MI): Cimatron is exploring software solutions exclusively for significant acceleration and automation of specific processes for toolmakers (such as tooling quotations, electrodes design and manufacturing, mold base design and toolpath process creation). Furthermore, we are both integrating and developing software for better management of the tooling manufacturing (TDM/PDM).

The ability to collaborate concurrently between 'best-in-class' experts - with input from suppliers, contractors, engineers and moldmakers - will dramatically affect the product development process for years to come. This advancement will enable engineers to get products to market faster and cheaper - with reduced development/ manufacturing time, fewer design changes and less travel. These solutions are changing the tools used by manufacturers from those focused on the individual desktop to those that encourage design collaboration and improve the flow of information and expertise throughout the enterprise and the extended supply chain.

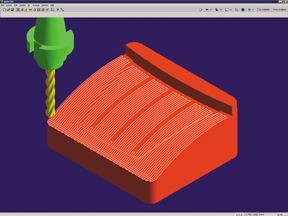

Pedro Leon, vice president for the Americas, Delcam International, Inc. (Windsor, Ontario): Delcam is automating each stage of the moldmaking and tooling processes with new modules to our packages. These include electrode generation for EDM, die block design, mold tool design and two forms of automated part or core and cavity inspection - on the CNC machine tool and with a coordinate measuring machine (CMM). But there are a lot more: combined machining strategies, allowing the CAM system to automatically select the most appropriate machining strategy based on the shape of the part or part feature to be machined; knowledge-based machining that builds into the CAM system guidance on the appropriate machining techniques given the physical properties of the part or tool; customization tools that allow users to automate those CAM processes that directly affect the unique ways in which work is done in each shop; and automatic CNC feedrate optimization designed to ensure that the optimum machining parameters are maintained at all times. This removes the need for machine tools to be constantly monitored and can reduce milling times by up to 50 percent.

Ben Mund, marketing manager, Mastercam/CNC Software, Inc. (Tolland, CT): This looks to be a year of major refinement and enhanced ease and simplicity rather than radical new departures. As an example, high-speed machining (HSM) is rapidly gaining popularity. Although this machining technique has been around for some time, it is only relatively recently that it is becoming more widespread. HSM requires very specific motion to eliminate sharp direction changes, so look to see CAD/CAM software adding more high-speed machining-specific motion.

Automated part cleanup is another area that is increasingly important. This requires a certain 'intelligence' to be built into the CAD/CAM software. The software can analyze the model after a roughing or finishing pass to determine what stock is left (for example, in areas where the tool was too big to fit), and create a toolpath to clean those areas only. Another example of automated part cleanup is 'pencil tracing,' where a tool walks along the edges of intersecting surfaces to produce a crisp, clean finish.

There are several mold-specific CAD tools that CAD/CAM packages make available and these will be increasingly important. Because CAD/CAM packages (as opposed to straight CAD packages) tend to approach projects from a machinist's point of view, specialty CAD functions can be very useful in making a model machinable. Specific examples include automatic core/cavity separation, moldlock and runoff creation, and fast, automated EDM tool creation.

One last item that is gaining importance is hybrid machining. The idea is for a CAM package to be able to accept and machine any type of CAD data - wireframe, surfaces and solids - and machine it all at once.

Shannon Hermanson, communications coordinator, SURFCAM CAD/CAM Systems by Surfware, Inc. (Westlake Village, CA): We should see advances in solids-based machining, improvements in high-speed machining toolpath algorithms, advances in knowledge-based machining, more affordable machine tool simulation and improvements in data translation.

How will these advancements affect the moldmaker, mold designer and the moldmaking process in general?

Marinac, Cimatron: Moldmakers will continue to be forced to deliver high quality molds with shorter leadtimes at lower costs. The moldmaker's ability to adapt to new technology will be challenged. Moldmaking-process specific, wizard-based automation will enable moldmakers to adapt to this new paradigm.

With the advent of moldmaking being a worldwide operation, moldmakers will have to get used to the fact that in order to remain competitive they will have to provide turnkey solutions back to their clients, and will have to alter their business model to provide for foreign competition by acquiring operations overseas or forming partnerships with Asian/European operations. The old adage 'if you can beat them, join them' can be extended to 'or buy them out!'

CAD/CAM software will have to be re-thought, re-architected and re-structured to take it off the desktop to make it available on the webtop. More and more software tools will not be loaded on the desktop, but executed directly over the web. This will push not only platform performance, but also bandwidth and inter-web processing design. This also will enable software developers to propagate narrow specialty programs to wider audiences and make specialized versions of broad applications.

The trend that most developers are working toward is offering moldmakers better predictability and interoperability. Predicting moldmaking performance via simulation and optimization will continue to be process-specific, offering many niche tools such as electrode design automation or manufacturing cost and analysis. The ability to leverage the digital model beyond engineering into new domains of users, services, procurement and logistics has been the biggest impact of the Internet, e-commerce and visualization technologies to the product development process.

Engineers have the ability to model any part on a 3-D CAD system. What they do not have is the ability to exchange their models with vendors, customers and colleagues who use different CAD/CAM systems for editing, design-for-manufacturing and manufacturing (open marketplaces). The use of pure geometry - such as that supported by industry standard data translators such as IGES, STEP, SAT and Parasolids - does not allow users the ability to modify solid models that lack parameters or features, as well as history-based solid models. As a result, teams cannot work on design projects together no matter what underlying CAD software is used.

Leon, Delcam: These advancements will reduce oolmaking leadtimes and costs. The moldmaker's two overriding concerns with customers are - as always in business - time and money. They are closely linked - the more quickly things get done the less they cost.

It's no secret that today the vast majority of CAD and CAM systems developed for moldmaking and tooling can achieve the advertised results. The key remaining differentiator among these packages is whether they have been designed to let the mold and tooling user work as quickly and effectively as possible.

Moldmakers will not, however, be helped unless they buy appropriate to their needs. Moldmakers need to do their homework before buying, choose carefully and ask other users a lot of very specific questions about how the software actually performs.

Mund, Mastercam: High-speed machining and automated cleanup can drastically reduce the machine time involved in cutting a mold. Mold-specific CAD tools also speed up the process by delivering sophisticated CAD tools designed specifically to turn CAD models into molds. And hybrid machining and the acceptance of any type of data into a single CAM package will increase a shop's flexibility and job potential.

Hermanson, Surfware: Together these technology advancements will make the job of designing and machining molds and mold components easier and more efficient. The level of software interaction required from engineers and NC programmers will be lessened due to the improved capabilities of the software, allowing them to focus their expertise more on overall process improvements, and less on mastering a complex software package.

What do mold designers need to know and understand about CAD/CAM in order to use it successfully to reduce a mold's leadtime?

Marinac, Cimatron: It is a given that the Internet (be it wired or wireless) will continue to play a major role in the development of new technology. This enables a truly distributed computing environment where everyone has access to anything on the worldwide network. It will allow everyone - not just product development engineers - to improve communications around the world. In the short term, engineers will be able to collaborate more effectively with their counterparts, suppliers and customers around the world. This will decrease their cost, improve their time-to-market, improve quality and generally allow them to make better products.

In the long term, central web-repositories will replace captive engineering knowledge bases, which capture and recycle product development knowledge. This knowledge will be re-used to dramatically enhance the design, engineering and manufacturing process.

Leon, Delcam: There is a huge variety of CAD/CAM systems on the market today. Users must sort through all of this to identify a system specifically focused on meeting their needs. The needs of moldmakers are very different than those of other CAD users.

Obviously moldmakers should ensure that the system they choose is focused on moldmaking rather than being general purpose design and manufacturing. The temptation to buy the latter can be very strong because those 'general purpose' systems are less costly. There are many reasons for moldmaking software's higher price.

For example, moldmakers work to a far greater extent than other designers with data from other systems. Systems that moldmakers purchase must have robust data translation. This is an area of constant change.

Another example is that CAD/CAM systems specifically developed for molds, tools and dies contain capabilities designed expressly to automate the time-consuming and repetitive processes a moldmaker goes through. These include splitting the core and cavity halves, creating slightly angled draft surfaces and automating EDM electrode creation. These tasks are not normally done by users of 'general purpose' CAD and CAM. Some of this functionality may be advertised as part of those packages. But from our customers' experience, these functions will be rudimentary, poorly integrated and hard to use. One very successful toolmaker once told us, 'I'm not so wealthy that I can afford to buy the cheapest system.' There is a lot of wisdom in that apparent contradiction.

Mund, Mastercam: They should have an understanding of the basics. Engineers will often design without machinists in mind, and as a result, that can cause difficulties as far as gaps in surfaces. You need your CAM software to have the ability to adjust to that, which most software already does. They should be familiar with all of the CAD data types, and the benefits and drawbacks of each. Another tip is to use the mold-specific CAD tools that are available with many packages. Those are really effective in reducing a mold's leadtime because they feature a lot of automatic design tools that help you finish the mold.

Hermanson, Surfware: They need to understand the role of CAD/CAM software in their environment. CAD/CAM software is a tool to help users do their jobs better and more efficiently, but it is not a substitute for knowledgeable and experienced engineers and NC programmers.

They also should take advantage of software maintenance/upgrade programs. CAD/CAM vendors continuously enhance their software to make it more capable and easier to use. Though software maintenance/upgrade programs vary from vendor to vendor, in general these programs provide the customer with a path of continuous improvement for their software investment. This is a time of rapidly advancing technology; it is important to keep current.

While it's hard to predict the future of a technology that is rapidly evolving every day, hopefully CAD/CAM manufacturers will continue to fine tune their software - continuing to simplify the design and machining of molds and answering moldmakers' requests for even more streamlined, automated operations.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More