Software Enhances Advancing Technologies

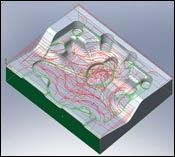

CAD/CAM’s improved features and new capabilities—combined with the latest in technologies like high speed and five-axis machining, new cutting tools and 3-D technologies—allow moldmakers to achieve the highest quality in the shortest time.

It is common knowledge that the industry has become increasingly competitive over the last decade—and moldmakers have responded in kind with shorter leadtimes while cutting costs and improving quality. To keep up with their customers, manufacturers and suppliers of CAD/CAM technology also have been pushing the envelope to create more sophisticated software that can address their customers’ needs. CAD/CAM technology must be able to work with advances made in cutting tools, high-speed machining and 3-D technology.

“Expanding global moldmaking has put the industry into a more competitive situation,” explains Ben Mund, Marketing Manager, Mastercam/CNC Software Inc. (Tolland, CT). “For example, the migration of mold work has moved from traditional strongholds to lower cost markets. Other leading moldmaking nations (like Portugal and Brazil for instance) are losing work to lower cost markets. Shops are being forced to reduce their own production costs and have had to invest in more efficient techniques and technologies, such as better machine tools and more efficient CAD/CAM software programs.

“Some mold shops are having to find more diverse work and looking at other means to make money,” Mund adds. “They are continuing with their existing mold work, but also are picking up other work in specialized applications taking advantage of their knowledge and machine capabilities, such as multiaxis machining. In this case, using your machine tools and CAD/CAM software package to their full potential in order to explore other areas of work can lead to dramatic success despite a reduction in some types of mold work.”

Peter Dickin, Public Relations Manager, Delcam, Inc. (Windsor, ON), notes that customer demand can be broken down into three categories—more complex tooling as designs become more sophisticated and part consolidation adds more features to each component; faster delivery times for tooling as part of the general demand for faster product development across all industries; and higher quality resulting from a growing emphasis on consistently better products and an increased inclination to resort to litigation if there are problems with product performance.

Market Changes

The CAD/CAM market has exploded over the past 10 years in terms of speed, sophistication and efficiency—in line with ever-shortening leadtimes. Advancements in PC hardware, design/engineering machining and cutting tools have resulted in CAD/CAM suppliers fine-tuning their offerings. Integrated CAD/CAM solutions also have evolved.

PC Hardware Advancements

It’s no secret that computer hardware has come a long way in the last decade—computer hardware that was prevalent back then is for the most part useless today. “Faster hardware means more robust software and mathematical algorithms/tolerances,” explains Vytas Cijunelis, Midwest Operations Manager, DP Technology Corp. (Des Plaines, IL). “If we were to try running a nominal level software engineering program on PC hardware that was 10 years old, the hardware requirements would be exceeded and the software likely would not run. So PC hardware technology is one of the most important advancements that affect the CAD/CAM market, as well as other relational markets. Without advancements in PC hardware, complex full-machine simulations, high tolerance toolpath calculations, etc. would not be possible.”

Design/Engineering

Design and engineering advancements also are a strong influence on CAD/CAM development, DP Technology’s Cijunelis continues. “For example, the advent of solid model kernel technology has allowed the sharing of data, features and machining strategies between products like never before,” he states. “Not only does the design work get easier with relational representations of part dimensions, but the CAM side also sees benefits. Those same features, diameters, lengths, etc. can all be automatically read by the CAM system—providing the user confidence in programming and automation. Once the machining parameters of a feature are “known” (i.e. the diameter, length, width, depth, type, size, etc.) this feature can be assigned a machining process (i.e. rough with tool 1, re-machine with tool 2, finish with tool 3) to cut at the machine, with confidence and efficiency. The technology behind feature recognition and knowledge-based machining would be perfect examples of the industry benefiting from this.”

Specialization

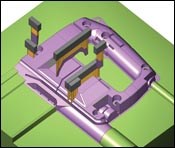

A decade ago there weren’t really any mold-specific design or manufacturing CAD/CAM applications available, notes Bill Genc, President, Clear Cut Solutions, Inc. (Addison, IL). “While there were CAD/CAM products, those products were never written specifically for mold manufacturing. I would say that the biggest change is that today there are applications that exist that actually are tailored to the moldmaking industry for both CAD and CAM.”

Mike Coleman, CEO, Geometric Technologies, Inc. (Scottsdale, AZ) adds his views. “There have been changes in the complexity of the product designs and the disconnect between design difficulty and manufacturing,” he notes. “It used to be that the correlation between design difficulty and manufacturing difficulty kept designers from creating designs which were too complex. Now complex designs are common because the designs are so easy to model.”

From 2-D to 3-D

With the amount of work performed in so many different applications, it is only natural that the industry gradually evolve from 2-D to 3-D. According to Jarrod Schmidt, Product Marketing Manager, VX CAD/CAM (Melbourne, FL), while 10 years ago mid-range 3-D solid modeling was becoming mainstream, the majority of mold designers were still using 2-D design tools. “Mold design-specific software packages that automate mold assemblies and facilitate parting surface were still only found in high-end, high-priced systems,” Schmidt says. “The late ‘90s and early 2000s we saw mold design approaching the mid-range, but without integrated manufacturing. It has only been the past six years that the CAD/CAM integration—along with automated mold design—has been available to the mid-range market. Many mid-range solid modelers still struggle with non-solid, imported, geometry. Some mold design systems provide excellent wizards for designing simple open/shut molds, but they fail when given something challenging. Large files and assemblies sizes are still an issue for many systems, requiring super high-end hardware and graphics cards. Some of the mid-range solid modelers still rely on third party products for rounding out their mold design offering, which can frustrate users for support, training and product updates.”

Delcam’s Dickin adds his thoughts about the advantages of going from 2-D to 3-D. “The real benefits come from the ability to maintain a fully detailed model throughout the design and manufacturing process,” he explains. “This minimizes the errors and misunderstandings that are inherent in 2-D drawings. In addition, the high degree of integration between CAD and CAM can be used to automate many of the manufacturing processes. Many of the changes on the CAM side have come from developments in related technology. For example, 5-axis machine tools have become much more affordable for moldmakers and CAM developers have responded with much easier to use 5-axis programming systems with a wide range of strategies for these new machines.”

The Emergence of 5-Axis

Bryan Jacobs, Marketing Communications Manager, CGTech (Irvine, CA) points out that in the past, mold machining was strictly limited to 3-axis milling. “As 5-axis milling machines became more affordable and mold designs became more complex, the use of 5-axis machine tools for machining of mold cavities has become increasingly more common,” he notes.

“Five-axis machining is significantly more complicated than 3-axis machining—requiring more sophisticated software to support the more complex processes,” Jacobs continues. “It requires manufacturing engineers with new skills to design efficient processes and create the NC programs for these machines. The engineer must have superior spatial visualization abilities and software tools to support his efforts. Machine simulation and path verification software—with accurate and reliable material removal simulation of complex 5-axis cuts using complex shaped cutting tools—is mandatory for efficient development of correct NC programs. Without the ability to visualize the cut surfaces produced by a complex 5-axis cut, the NC programmer is forced to imagine it himself, or wait to view the physical results when it is too late to change.”

Alan Levine, Managing Director, Open Mind Technologies USA, Inc. (Wellesley Hills, MA) adds that that implementation of 5-axis software allows for shorter and stiffer cutters and one setup. “This also improved the quality of results,” Levine notes.

High-Speed Machining/Cutting Technologies

Advances in these technologies have led to CAD/CAM improvements. “Hard metal cutting and high-speed machining have been improved dramatically due to the new cutting algorithms available,” notes Bede Kortegast, Vice President Sales North America, SolidCAM USA (Seattle, WA). “The toolpaths generated allow for almost polish-free finishes, longer tool life and less stress on the CNC machinery. All of this and the skill and effort needed to program the parts have been reduced. All in all the software has made programming time, machining time and polishing time drop—in some cases—more than 50 percent.”

CGTech’s Jacobs adds to these thoughts. “Current cutting tool designs, when used correctly, can produce phenomenal results,” Jacobs notes. “Incorrect use of these tools on hard materials such as improper feedrates and spindle speeds, too large or too small radial or axial depths, poor approach, engagement, or orientation to the material, can cause these tools to wear prematurely or even break.”

Dickin of Delcam points out that developments in cutting tools have made it possible to use feeds and speeds for machining that would have been unthinkable 10 years ago. “CAM systems now feature many dedicated strategies for high-speed machining that allow the maximum benefit to be gained from the new classes of cutters,” Dickin emphasizes. “The other major change has been in the development of more accurate and more realistic simulations of the machining process on the computer. These give users extremely high confidence that what they see on the computer is what will happen on the machine tool. Together with improved collision avoidance routines in the software, these simulations have enabled much more widespread use of lights-out machining. Again, this mitigates the benefits of manufacturing in countries with lower labor costs.”

“We in NC programming software saw the need to develop revolutionary code capable of maximizing the advantage of these new cutting tools,” adds Stephen Diehl, President of Surfware Inc. (Westlake Village, CA). “The solution is in patent-pending cutter engagement control. This new method should not be confused with CAM software that only controls the load on the tool.”

Machining to Zero

According to Levine of Open Mind Technologies, CAD/CAM has had a major impact on machining to zero. “This technology is only possible today due to improvements in machining process technology. There are many contributing factors to allow this approach, which include: machine tool improvements/CNC control improvements that allow accurate processing of more data; improved improve toolholders (shrink fit for example) that keep cutters concentric and allow for closer tolerance machining; coated cutters that withstand high temperature and have longer life, thereby assuring higher quality components; integrated CAD/CAM systems that produce models exactly to the design, without intermediate translations and potential loss of quality; implementation of 5-axis software to allow shorter and stiffer cutters, one-setup, etc. that also improve the quality of results; and increased computer speed and process that allow improved mathematical approaches to CAM systems.

Integration/Consolidation

Today, more and more companies are seeing the benefit of using an integrated CAD/CAM solution, Genc of Clear Cut Solutions maintains. “In an integrated environment, the CAD environment is the same as the CAM,” Genc says. “However, today there are only truly a handful of CAD/CAM vendors that can provide this type of integration. Most companies today are working in a ‘forced integration’ environment, which means that companies might use CAD product X because it is a strong parametric solid modeler, while at the same time use CAM product Y because it actually runs inside of Product X. The problem with this method is that both products are developed by two different companies. While they give the appearance of integration, they really are not truly integrated. Being an integrated product means that one is working in an environment that is not only truly seamless, but was developed that way from day one. Working in an integrated environment means that critical manufacturing information is automatically handed downstream to the CAM software (without the end user having to teach the software).”

Cijunelis of DP Technology notes the importance of collaboration and consolidation—including outsourcing. “We take something like IGES for granted, but if there were no standards, sharing information would be a mess,” he comments. “As technologies are bought and shared, the market evolves as a whole. In the last 10 years, we’ve seen a high level of consolidation as companies were bought and technologies merged. Not only does this reduce costs to the end user, but ultimately, the solutions provided are more robust.”

Product Line Developments

Software manufacturers have added a number of enhancements and upgrades to their product lines to address the aforementioned industry advancements. Schmidt of VX says “Many of the enhancements included in VX CAD/CAM over the past 10 years have focused on providing productivity gains our mold customers need to remain competitive,” Schmidt notes. “Furthermore, with advances in computer technology today’s CAD/CAM software is far more powerful and requires a far less expensive platform to run on than ever imagined 10 years ago.”

Cijunelis of DP Technology says that technology advancements are not limited to NC programming or design engineering software. “Higher tolerances with CAM software relate to shorter machining times and more accurate parts off the machine,” Cijunelis comments. “This reduces overhead by reducing the need to post process the parts after they leave the machine because they are more accurate when cut.”

Detailed below are specific changes to CAD/CAM product lines over the past decade.

Hardware Evolution

Genc of Clear Cut Solutions believes some of the most significant CAD/CAM product improvements relate to hardware evolution. “Computers are around six times faster now than they were 10 years ago, and can handle larger amounts of data today,” he states. Because of this evolution in computer hardware, software companies have been able to improve their algorithms to take advantage of faster processors, larger amounts of memory, faster graphics accelerators.

“That said, an average two-cavity mold that has a couple of side actions and lifters could most likely be designed in as little as half a day today—depending on complexity of course,” Genc adds. “

Integrated Software

Kortegast of SolidCAM USA notes that the company’s entire product set has moved from stand- alone CAM into integrated CAM. “The demand of the design force and its both logical and best practice is to have the same database shared from conceptual design through to the manufactured part,” Kortegast emphasizes. “There is no longer the need to create the concept in one software, hand off to a second to flesh out the design, then go to a third and fourth for mold design and flow analysis and finally produce the toolpath in a fifth separate product. This can all be done in CAD design tools. If a change is made at the start of the process or anywhere in between, that change ripples through and updates the whole process.”

Ira Baraket, Corporate VP Sales & Marketing, Cimatron Technologies, Inc. (Novi, MI) weighs in on this concept. “In this context, CAD/CAM software is no longer viewed as an application for the individual designer or programmer, but rather as an organizational platform that must support the entire mold production process,” Baraket affirms. “The ability to support collaboration, concurrent engineering, integration and streamlined processes are becoming the most important attributes for moldmakers when implementing CAD/CAM solutions.”

Better Features

In addition to integration, CAD/CAM’s specific features are evolving as well. Mastercam’s Mund notes that the drive for faster turnaround times had resulted in more automatic cleanup tools with built-in knowledge. “These tools minimize—or even eliminate—the labor-intensive benchwork that was required in the past.”

Similar improvements have been developed by Delcam. “The introduction of ‘Wizards’ has automated many stages of the design process—including the creation of the core and cavity, the addition of slides to accommodate undercuts in the product design, and the assembly of more of the mold from catalogs of standard components,” Dickin says.

Genc of Clear Cut Solutions emphasizes the importance of the evolution of libraries. “Ten years ago, designers were for the most part drawing these items from scratch, or if they were truly ahead of the curve, had built themselves some basic reusable 2-D libraries,” he says. “Today, when an ejector pin is inserted into the 3-D design, the software is smart enough to trim the pin to the molding detail, put the correct engagement for the pin into the design, add all of the standard clearances needed in all of the different mold plates, and even key the pin if needed. This is a process that takes only a few seconds today. The designer used to do this 100 percent on his own. He had to remember to modify the design of each plate themselves. This could take 20 to 30 minutes per ejector pin. So if the designer had to put 50 pins into a design 10 years ago versus today—do the math as it is easy to see where the improvements come in.”

NC Program Optimization

Jacobs of CGTech notes that there were major advancements in NC program optimization technology about 10 years ago. “In 1998, as high-speed machines were becoming more and more popular, a chip thinning technique for these types of machines was introduced,” Jacobs recalls. “Chip loads typically vary widely as the tool profiles through the material left behind during roughing cuts and over the contours of the workpiece to near net shape. Optimization software that knows how much material is being removed can adjust the feedrates to maintain a constant chip load. (Consistent chip loads are recommended by cutting tool makers to reduce chip thinning.) The results are improved tool life and better finish. This is especially critical when tip cutting with a ball end mill or contouring a surface with a small step-over, such as semi-finishing or finishing in a tool steel mold cavity, for example. The optimization software knows exactly how much material will be removed in each segment of the cut and slows the feedrates down where the load is too great. This prevents breaking cutters and keeps the machine from exceeding horsepower limitations.”

Cutting Tools/End Mills

To make use of the new high-end solid carbide end mills that are now available, Surfware’s Diehl explains that the company’s CAM software needed to control not only the standard cutting parameters, spindle speed, feedrate and depth-of-cut, but most importantly, tool engagement. “Software that controls tool engagement allows the tool to be consistently used at its optimal cutting conditions,” Diehl says. “Now we can use high-speed machining techniques on pre-hardened mold materials anywhere from 30 to 50+ RC range.

“The new cutting tools work superbly on straight line cuts, but still encounter problems in corners,” Diehl continues. “We developed toolpath generation methodologies that enable the cutting tool to machine complex geometry with the same cutting conditions as a straight line cut. This enables high material removal rates at a depth-of-cut of up to two times the tool diameter, taking maximum advantage of these new cutting tools. We control the engagement angle to eliminate the spikes in tool load that typically occur when the tool encounters a sharp corner. Because there are no spikes in the tool load, the tool can be run at its best straight-line cutting conditions regardless of the part geometry, and without danger of breaking.”

High Speed/Five-Axis Machining

“On the CAM side, developments have continued in high-speed machining and 5-axis machining so that customers can gain the maximum benefit from their investment in new machine tools,” Dickin comments. “The time savings possible depend on the size and complexity of the product design. Two typical examples from our customers are a reduction from an average 30 days to produce a mobile phone mold down to 11 days, and a reduction from 22 weeks to 16 weeks for large automotive tooling for door panels, dashboards and fenders. These examples are both for full-scale production tooling; of course, short-run prototype tooling can be manufactured much more quickly.”

Solid Models

According to Mund of Mastercam, there has been a great increase in the use of solid models in the past 10 years. “It is crucial that CAD/CAM software be able to cut any mix of wireframe, solids and surfaces,” Mund explains. “Powerful cavity routines and automated EDM electrode creation are also increasingly important features for a moldmaking software package.”

Better, Stronger, Faster

The CAD/CAM suppliers see this market continuing to grow more integrated and sophisticated as molds get increasingly complex. “As technology evolves, CAD/CAM software will show continued advancement in intelligence and automation,” Mastercam’s Mund notes. J

Integration/Automation

Integration and automation are key concepts to the markets future per Genc of Clear Cut Solutions. “I am already seeing this today,” he states. “Companies are tired of trying to force their different technologies to ‘play nice with each other.’ I think that we will see a large push towards integration because of the ability to create powerful automation this way. I would also not be surprised to see CAD/CAM products become even more intelligent over the next 10 years. I believe that with the improvement of hardware, software will be created that will do some very amazing things. For example, I have seen a mold design software that can automatically create the entire 3-D mold design for simple parts without any actions. This software even includes the 2- assembly drawings, details with full bill of materials. I think that in the future we will see applications like this be able to handle more and more complicated parts—to the point where the only thing the designer is doing is managing the process. I would also not be surprised to see software products become even more intelligent with regards to manufacturing. For example, as a designer is designing, the software is validating the design for manufacturing based on what your company is capable of manufacturing.”

Levine of Open Mind agrees. “We forecast the continuing acceleration of CAD/CAM solutions in the market,” he notes. “Key points include integrated CAD/CAM solutions, more automation through feature recognition and stored macro procedures, greater utilization of 5-axis technology (for fewer set-ups, fewer processes, and higher quality).”

Adds VX’s Schmidt, “Data exchange will still be an issue—and as a result—open-shape modeling will remain critical and useful for the mold manufacturer. We’ll also see a greater requirement from customers for more automation in designing mold assemblies, and for the tight CAD/CAM integration already found at our company to continue with perhaps an even more seamless transition and more CAM automation with a focus on intelligent machining.”

Market Stability

Dickin of Delcam believes the tooling market show much greater stability, although at a lower level than 10 years ago. “The simpler tooling is now made outside North America, and the larger, more complex tooling that is needed urgently will not be moved overseas,” he comments. “There may even be some reversal of the off-shoring trend as more automation and higher delivery costs, plus increasing wages in the cheap labor countries, reduce the cost advantages of manufacturing overseas. The general trend in CAD/CAM will continue with faster calculation times as computers become more powerful and more automated methods for the design and assembly of molds. The introduction of faster and more sophisticated machine tools is certain to continue and CAM developers will need to ensure that their software keeps up with these improvements.”

Diehl of Surfware forecasts that improved CAD/CAM systems that generate tool paths based on engagement control will increase the efficiency of machining, lower the cost of making molds, reduce leadtimes and achieve a quick return on machining software investment. “As a result, much of the mold work that U.S. companies outsource to other parts of the world will return to the United States,” he notes. “High global fuel demand will raise prices to a level that will further draw manufacturers away from the economy of outsourcing towards distributed, local production sites. Quality control, security issues and demand for customization will further reverse vertically centralized manufacturing and will increase demand for trained, high-wage workers.”

SolidCAM USA’s Kortegast predicts that work will come back from what were the lower cost outsources in Asia. “The cost to ship, lead times and guarantee of quality will no longer make offshore outsourcing viable,” Kortegast says. “The danger is that in the meantime the resource pool of qualified tool and die makers is diminishing. It will require ‘re-tooling’ of the U.S. manufacturing education programs to keep that pool filled.”

Ease of Use

CAD/CAM software will become even more intuitive to learn and easier to use, says Surfware’s Diehl. “This is especially important because the industry is losing those old-time journeyman machinists who know by the sound how well the cutting is going,” he notes. “Sadly, in time there may be no one left with 30 years of hands-on experience and a satisfying gut-knowledge of metal cutting. That critical know-how may eventually be transferred entirely to computer code.”

“The industry will continue to be challenged from different directions,” notes Baraket of Cimatron. “The trend toward mass customization will continue driving manufacturing toward shorter production runs, which in turn will put more pressure on moldmakers to reduce costs and increase the flexibility of the tools they make to support multiple part designs and frequent engineering changes. Efficiency gains in individual tasks are reaching the point of diminishing return. Productivity improvements in the next 10 years are more likely to come from process improvements: reducing setups (for example, using 5-axis technology), reducing idle time between steps (with 100 percent concurrent engineering being the ultimate goal), no file or format translations, minimizing the cost and time of engineering changes, and greater reusability of components in both design and manufacturing.”

Up and Coming

Jacobs of CGTech believes that U.S. moldmakers will continue to be challenged to be competitive in the face of low-cost offshore labor and must continually investigate, invest in, and use the latest and best available technologies in order to continue in business. “Possibly in the future, the use of 5-axis machine tools will be required to be competitive, at least for creating molds of a certain complexity and sophistication,” Jacobs states. “Automation requires software. Which software is used, and how it is applied will be the significant differentiator for successful moldmaking companies. Those who economize on software will pay the price later in their processes.

While Cijunelis of DP Technology points out that the aforementioned trends of automation, visualization, consolidation, collaboration, etc. will continue to evolve, there are new concepts out there that will enter into the picture. “For example, the merging of manufacturing strategies on one machine will become commonplace,” he says. “We are seeing more OEMs designing machines that combine the aspects of milling and turning in one machine. This is very useful for parts that require multiple setups and a need to reduce overhead is desired. Rotary and fifth axis capabilities also are becoming more cost-effective for shops to acquire. We are seeing the combination of other technologies as well—such as EDM with waterjet on one machine. So, it will be quite exciting to watch the industry as the next 10 years unfolds!

Related Content

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More