Makino Inc.

7680 Innovation Way

Mason, OH 45040 US

800-552-3288 | 513-573-7200

webmaster@makino.com

makino.com

IS THIS YOUR COMPANY?

Video Gallery

Wire Evacuation on the Makino UX series Wire EDM

In this quick tech tip, learn how the pinch rollers on a Makino UX series Wire EDM machine keep the wire evacuation clean and ...

Ease of Access on the Makino UX series Wire EDM

Take a look into the back of a Makino UX machine and see how the machine design enables easy access for maintenance tasks.

The Wire Drive System on the Makino UX series Wire EDM

In this quick Tech Tip, we explain the HyperDrive Extreme Wire Drive System on a Makino UX series Wire EDM machine and how ...

Motion Control on the Makino UX Series Wire EDM Machine

Learn how the motion control system on the Makino UX series Wire EDM machines improves accuracy and helps achieve tighter ...

As Seen On MoldMaking Technology

Makino Inc. Supplies the Following Products

- Boring Machines

- CIM (Computer Integrated Manufacturing)

- Drilling Machines

- Five-Axis Machining Centers

- Graphite Electrode Machines

- Grinding Machines

- High-Speed Machining Centers

- Horizontal Machining Centers

- Milling Machines

- Sinker EDM

- Small Hole EDM, or "Hole Popper"

- Vertical Machining Centers

- Wire EDM

Editorial, News, and Products

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Innovation, Diversification and Integration Guide Mold Builder Growth

Quality Tool and Die team discusses the journey from a small automotive tool shop to a diversified full-service moldmaking and plastic production facility.

-

Overcoming Barriers to Automation Integration in Precision Moldmaking

It’s easy to imagine the advantages automation offers the moldmaking process, but it's challenging to change one’s mindset, develop a plan and invest.

-

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

-

Exploring New Markets, Fostering Innovation and Embracing Sustainability

What follows is a Q&A with Gabe English, an MMT EAB member and president of Western Carolina Tool & Mold.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

North Carolina Mold Builder Works With Purpose and Partnership

Adapting and innovating amidst a change in ownership, doubling sales and maintaining the workforce reflects team resilience and expertise.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Triple Threat: How One Shop's Success Resonates Across Three End Markets

When I revisited Eden Tool in New Freedom, PA, this past summer for a follow-up feature on this mold builder’s growth, I underestimated the story.

-

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

-

Openness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

-

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

-

Indiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Next-Level Mold Manufacturing Highlighted at MoldMaking Conference: Data, Communication, Collaboration

Owners, engineers, operations managers, toolroom managers, apprentices and more left the MoldMaking Conference with a list of real-world tips, fresh ideas and new connections to bring back to their teams.

-

Most-Viewed Content of 2022

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

-

Midgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

-

Small, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

-

Are You a Next-Level Mold Manufacturer?

Introducing the MoldMaking Conference for the next-level mold manufacturer because moldmaking has moved beyond art and craft to science with technology advancements aimed at engineering and building a better, more cost-effective mold.

-

The MoldMaking Conference: General Sessions on Tooling Digitization and Design Apprenticeships

Here we spotlight the General Sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

The MoldMaking Conference — All About Next-Level Mold Management

Here we spotlight the Manage block of sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

The MoldMaking Conference: All About Next-Level Mold Maintenance

Here we spotlight the Maintenance block of sessions of the MoldMaking Conference – for the next-level mold manufacturer – November 8 & 9 in Charlotte, North Carolina.

-

The MoldMaking Conference: All About Next-Level Mold Building

Here we spotlight the Build block of sessions of the MoldMaking Conference on November 8 & 9 in Charlotte, North Carolina.

-

MMT Chats: Using Predictable Manufacturing to Create a Mold Insert at IMTS

MoldMaking Technology Editorial Director Christina Fuges and Eden Tool & Eden Manufacturing President Dave Tomic sit down to discuss predictable mold manufacturing. Specifically, they discuss Eden Tool's machining strategy and the mold insert featured at IMTS 2022. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

Bringing Market-Specific Engineering Experience to Every Project

Experience, acumen and attention to detail help Prodigy Mold & Tool create value and build long-lasting customer relationships.

-

MoldMaking Conference: All About Next-Level Mold Manufacturing

Next-level mold manufacturing is dependent upon accurate, repeatable and efficient technologies, processes and talent when it comes to designing, building, maintaining, repairing and managing molds. It is with this focus in mind that we are launching The MoldMaking Conference on November 8-9 in Charlotte, NC.

-

MMT Chats: Molding Capabilities Yield New Customers, Team Growth

MoldMaking Technology Editorial Director Christina Fuges chats with Eden Tool and Eden Manufacturing team members to get an update on this mold builder’s move into medical molding, technology investment, team training, Amerimold, and yes, hot rods. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

How to Cut Mold Machining Costs in Half

How to hard mill and finish grind in a single setup, including an in-machine probing inspection.

-

Webinar: Closed-Loop Jig Grinding: Hard Mill, Verify, Grind, Verify

Machine tool builder answers the lack of labor challenge that is creating bottlenecks while also living up to surface finish, tolerance and cycle time requirements with a closed-loop jig grinding and tolerance control process.

-

Automation Opens Door to New Possibilities and Need for More People at Minnesota Mold Builder

Increasing automation throughout the shop with both palletization, EDM and five-axis machining has allowed Mold-Tech to grow in technology, throughput, and people.

-

Shared Engineering Expertise Overcomes Design and Delivery Challenges

Collaboration on part and mold design between a molder and mold builder were vital to overcoming design and production challenges for a unique automotive project.

-

Diversification and Departmentalization Drive Growth for Wisconsin Mold Builder

New ownership at Innovation Mold & Design (IMD) grows the company by investment in technology that serves a departmentalization and diversification, business model.

-

Makino, Additive Technology Partner to Upscale Additive Manufacturing

Instead of treating additive manufacturing of metal parts and post processing as separate processes, the joint project aims to develop integrated process chains to establish upscaled AM.

-

CGTech, Makino Renewed Partnership Continues to Provide Manufacturing Solutions

The renewal of the strategic corporate partnership is ensure better serving of the company’s mutual customer bases.

-

A Blueprint for Die-Mold Shop Automation

An increasing number of mold and die makers are considering automation to get better utilization of their equipment and skilled people. While it will take good planning and execution, there is a manageable path to automation that will bring efficiencies to tool shops in ways hardly imaginable only a few years ago.

-

VIDEO: 2020 Leadtime Leader Award Winner: Precise Tooling Solutions Inc. — The Power of People and a Plan

The proof is in this winning shop’s three-pillared value proposition and three-phase growth plan that promotes empowers people while promoting quality product and profit.

-

Accu-Die & Mold Excels in Die Cast Tooling with a Focus on Service, Engineering, and Precision Manufacturing

Accu-Die’s highly trained workforce, well-equipped shop are key to meeting the challenging demands of die-cast mold production.

-

Advancements in Quality Processes and Value Added Capabilities Keep M&M Tool and Mold on Top

This five-time Leadtime Leader shop has added a full quality lab and expanded its service capabilities as part of a newly formed strategic tooling business unit.

-

Tooling, Tariffs and Reinventing One's Business for the "New Normal"

Mold industry professionals attending the Makino Technology Expo learned they must prepare for the “new normal” and build a better marketing and sales plan.

-

Cutting Edge Strategies for Optimizing Milling and EDM

Makino Technology Expo focuses on high-precision machining and digital technologies to advance moldmaking.

-

Multiple Pathways to 5-Axis Machining of Molds and Dies

Five-axis machining can dramatically improve the quality of a mold as was well as reduce the time required to machine it. What level of five-axis technology best fits your shop? Here are some options.

-

Makino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

-

Seasoned Moldmakers and Advanced Technologies Give Del-Tool A Cutting-Edge Advantage

For Del-Tool Co. Inc., a seasoned crew using automation, five-axis CNC and shop management software is the edge needed for continued success.

-

Can You Recommend Any Books on Mold Design and Manufacturing?

Mold industry pros rally to offer a list of resources in response to a fellow SPE member’s call for assistance.

-

Noteworthy News: Plan On It

There’s always something exciting going on in the moldmaking community for you to attend and learn more about the latest company updates and technologies.

-

2019 Technology Review: Machining

MoldMaking Technology’s 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including machining.

-

Amerimold 2019: Machining for Moldmaking, Part 1

Amerimold attendees saw many different types of machining centers, all posessing features for advancing the moldmaking process. Here are a few highlights.

-

New Machining Center Built for Speed and Precision

Makino announces the F5 Pro6 vertical machining center designed to provide rigidity, accuracy and agility for machining complex, 3D contoured geometries.

-

Sinker EDMs Increase Productivity and Reduce Electrode Wear

Makino releases an upgraded version of the high accuracy EDAF2 and EDAF3 Sinker EDMs with developments that increase productivity while reducing electrode wear.

-

Buss Precision Mold Reaps Success from Building Complex and Reshored Molds

A shift in core competencies, including re-shored molds, gives Buss Precision Mold an edge on high-precision moldmaking and laser-focused customer service.

-

VIDEO: How Five-Axis Continuous Machining Can Advance the Manufacture of Complex Molds

MoldMaking Technology Senior Editor Cynthia Kustush interviews Greg Pozzo, applications team leader for Makino, to learn more about the company's introduction of five-axis continuous machining and its benefits for moldmaking.

-

The Most Viewed Products of 2018

MoldMaking Technology wraps up the year by showcasing the most-viewed products of 2018.

-

CNC Machining Cell with Robot Elevates Production and Savings

Cooper Tires speeds tire-mold production with advanced CNC machining and automation technologies.

-

Collaboration, Flexibility, Speed and More at IMTS 2018

Attendees walked the miles of aisles to find that IMTS 2018 delivered it all and so much more.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

Automation and Connectivity Drive Machine-Tool Innovations

Machine tool and EDM suppliers are advancing their offerings to include automation, better controls, machine monitoring and new five-axis capabilities.

-

Scenes from Amerimold 2018 in Novi, Michigan

From technology demos and tech talks to awards and arcade games, Amerimold had much to offer industry this year.

-

Spindle Core and Jacket Cooling System Control Machine Heat

Makino's compact D200Z machining center has 30,000-rpm, HSK-E50 spindle that is designed with a high-tech spindle core and jacket cooling system to tightly control thermal growth, deflection and vibration during high-speed machining operations.

-

Vertical Machining Center Reduces Handwork in Complex Molds

IMTS 2018: Makino says that the V90S is designed for high-speed finishing of multifaceted, 3D contours and that it cuts cycle times and reduces handwork in complex dies and molds.

-

Horizontal Machining Centers Are Not Just for Big Manufacturing

Horizontal machining centers can help reduce the coolant, perishable cutting tools and labor costs associated with running a machining center in shops of any size.

-

2018 Technology Review and Sourcing Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including EDM.

-

Scenes from Amerimold 2018, Part 2—Education!

MMT brings readers yet another look at Amerimold 2018. This time, the focus is on education via our Tech Talks, technology demos and more.

-

Connecting Mold Builders and Buyers at Amerimold 2018

Mold buyers and builders experience many of the same challenges for which they are each seeking solutions and that is where Amerimold comes into play.

-

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

-

Tradeshow Tuesday: On Display at Amerimold 2018, Part 3

Amerimold 2018 is coming up! Plan ahead by checking out this week’s slideshow, which highlights some of what will be on display at the show.

-

Get Up Close and Personal with Technology Demos at Amerimold

On top of our show floor Tech Talks, the event offers attendees the opportunity to see live presentations at select exhibitor booths on a specific technology or process, while demonstrating how it works live on the show floor.

-

Continuous Five-Axis Machining Method Reduces Tooling Costs

Makino introduces a line of five-axis continuous machines that rely on a continuous five-axis method to reduce tooling costs for die and mold machining.

-

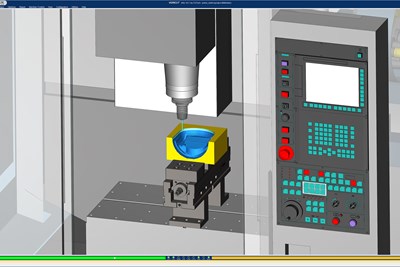

Display Features Integration of Machining and Automation

Makino demonstrates graphite machining, EDM and automation in a combination of machine center and production cell at NPE2018.

-

Milling and EDM Automation Reshape Summit Tooling’s Mold Operations

Summit Tooling President Dan Martin credits the capability to run unattended machining 24/7 to the partnership that his company built with Makino.

-

Hard Milling Gives Eden Tool a Competitive Advantage

Hard milling proves to be a strategic advantage for a small mold shop that runs lean and serves the medical device market.

-

Technology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

-

Technology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

-

EDM Machine Has Power Optimizer to Reduce Machining Time

The Edge2 EDM machine from Makino incorporates SuperSpark4 and Intelligent Expert System technology for increased accuracy and efficiency.

-

Do You Make a Lasting Impression on Customers... and Youth?

Cavalier Tool and Manufacturing Ltd. (Ontario, Canada) is one mold manufacturing company that likes to leave a lasting impression.

-

Realizing EDM's Full Potential with Automation

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing.

-

Technology Tuesday: EMO Wrap Up on EDM, Automation and Industry 4.0

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing. EDM technology is evolving through new machine designs, thermal stability, powerful generators, parts handling robots, linear handling systems and software solutions for future Industry 4.0 infrastructures.

-

Using Automated Technology to Fill the Skills Gap

Process automation is one of the fastest-growing strategies for overcoming capacity constraints in a mold shop.

-

Moldmakers Share Benefits of Makino Die/Mold Expo

Three mold manufacturers share their takeaways from the recent Makino Die/Mold Expo.

-

Three Takeaways from Die/Mold Expo

What do you gain by attending events like the Makino Die/Mold Expo that was held last week at the company’s Technology Center in Auburn Hills, Michigan? I asked a few of the moldmakers I met there to share their personal takeaways.

-

Invest Now in Die/Mold Automation to Meet Growing Customer Demand

In today’s highly competitive global marketplace, there are two types of mold shop owners, (1) those who invest in new technology and automation to create innovative ways to meet customer demands for shorter lead times, more complex designs and tighter tolerances and (2) those show don’t invest and quickly fall behind other North American shops and low-cost, offshore manufacturers. Here is a case study from Makino about one mold builder who fits nicely into type number one.

-

Technology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

-

Machinery Additions Accelerate Shop’s Growth

Six new Makino machines and updated processes allowed this moldmaker to penetrate new markets.

-

Adopting Automation

Shops are facing increased demand for shorter lead times, improved quality and lower costs. Automation offers several key advantages for overcoming these challenges.

-

Can You Prove It?

IMC can. Technology and processes I saw during my visit proved to me that they are still living up to their motto that if you take care of your customers and give them the best products at an affordable price, you’re going to do well.

-

Discover New Mold Building Strategies

Amerimold is The Event for Mold Manufacturing! Our speakers are geared to share case studies and best practices that will inspire and motivate you.

-

Preparing to Automate

One of the many presentations at Makino's recent Technology Expo covered die/mold automation. Here are a few takeaways on things to think about early in any implementation.

-

Makino Showcases CNC, Software Advances

Here are a few examples of developments unveiled at the machine tool builder's 2015 Technology Expo in Auburn Hills, Michigan.

-

2015 Leadtime Leader Awards Winner: Cavalier Tool & Manufacturing - Setting the Pace Holistically

This mold manufacturer has radically transformed its business by instituting a standardized, flexible process, advanced technology and a people-centric philosophy.

-

2015 Leadtime Leader Awards Honorable Mention: Dynamic Tool & Design - Committing to a Scientific Process

This shop’s recent strides in mold qualification mirror an ongoing transition to a more systematic approach to mold manufacturing. Meanwhile, a culture of ownership ensures a full buy-in from veteran employees as well as fresh talent attracted through extensive workforce development efforts.

-

Flexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

-

VIDEO: The Value of Collaborating with Competitors

This story about a palletized HMC offers lessons about more than just technology. It also demonstrates the value of keeping lines of communication open with peers.

-

Adopting a Production Mindset

An HMC with a pallet changer and modular fixturing system has streamlined job change-overs at this Tier 2 automotive toolmaker.

-

Minding the Business

This toolmaker and low-volume injection molder’s diversification shows that business savvy can be just as critical to success as an efficient manufacturing process.

-

All According to Plan

This moldmaker influences its own destiny by staying true to itself, knowing exactly where it wants to go, and ensuring everyone in the organization understands how to get there.

-

Truly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

-

Critical Equipment at Aalbers Tool & Mold

EDMs that have slashed burn time by a third and two five-axis machining centers are among the latest equipment implemented at the winner of this year’s Lead Time Leader—Honorable Mention award.

-

2014 Leadtime Leader Awards Honorable Mention: Aalbers Tool & Mold Inc

A rush of recent change for this moldmaker belies a long-term growth strategy that’s anything but aggressive. Key aspects of this cautious approach include strategic expansion, continuous improvement, extensive data tracking, and investments in workforce development and environmental sustainability.

-

From Craft to Science

For this shop, efforts to adapt to technology that reduces the need for human labor have driven a fundamental and ongoing shift to a more standardized manufacturing process.

-

Investing More Than Finances Yields True High-Performance Machining

Batesville Tooling & Design is a family-owned company that manufactures complex injection molds. The company took its first step into high-performance machining in 2012 with a Makino F5 vertical machining center.

-

Implementing Automation

The first two shops I’ve visited as an editor for MoldMaking Technology have made major strides in implementing automation. They’ve also expanded their range of capabilities to cover more than just tooling.

-

Hygienic Ice Cream Cones, Thanks to CAM Software

CAM software ensures that ice cream vendors have an added degree of hygiene by allowing for the manufacture of a product that ensures the ice cream vendor doesn’t have to touch the waffle cone.

-

2013 Leadtime Leader Awards: Winner Tech Mold Inc.

A three-division approach, technology innovation and a grow-your-own skilled workforce allows this mold manufacturer to balance the entire moldmaking process — ensuring continued success and landing it this year’s 2013 Leadtime Leader Award Winner title.

-

Automated Hard Milling Expands Capacity, Capability

“The key to investing in new machinery is to get more work done with the same amount of people, not the same amount of work with fewer people. To accomplish this, you need automated machining capabilities that are both flexible and reliable."

-

Simple Considerations for Automated Mold Machining

A streamlined approach to your mold manufacturing process is accomplished most effectively through machine automation.

-

VMC for Large Molds

F8/F9

-

Unique Mold Challenge Showcases Moldmaker as Customer Consultant

Ultimately, the Roembke Mfg. mold was a single-drop cold deck with a standard LSR valve gate design featuring side injection versus back injection for the plastic.

-

Motorola RP Services: 20,000 Electrodes and Counting

Motorola has placed an increased emphasis on adding new software tools to improve its engineering and manufacturing operations. For its moldmaking business, this has meant implementation of new procedures in Cimatron-E and implementation of a Hexagon PC-DMIS solution on the shop floor.

-

Cavalier Tool Tells Its Story at IMTS

Cavalier Tool & Manufacturing Ltd. of Windsor, Ontario, explained on Monday during Makino's Lunch & Learn how it handles drilling, boring, thread milling, tapping, 2-D and 3-D machining without the operator ever touching the part. Cavalier Tool believes that technology is increasing at a tremendous rate, which demands that they keep up with the latest innovations, and in order to do this they developed an in-house program that continuously analyzes their current technology, makes recommendations based on the current technology and replaces older equipment with newer, faster automated machinery. On average, three to four pieces of equipment are replaced annually through this program.

-

Automation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

-

Making What Matters

A “Make What Matters" campaign has recently been launched to recognize those who have make contributions to the advancement of North American manufacturing. It is nice to see companies that applaud their customers' efforts instead of merely selling their products!

-

Breaking the Mold with Automated Cellular Production

When Precise Tool & Die (Willoughby, OH) was founded in 1969 with one lathe and a Bridgeport, owner Steve Hunyati was worried about competition on the other side of Cleveland. Building a successful mold and die shop that thrived into the ’80s took persistence and vision, and those qualities served the company well even as it saw future competition—and opportunity—grow on the other side of the globe.

-

Machining Outlook: Reap the Benefits of Technology Advancements Working Together

A roundtable of machine tool suppliers reviews the advancements in machining technologies that push machining and tooling to their limits—and can kick every moldmaker’s capability up a notch.

-

Five-Axis VMC

See Us at Booth #783

-

Technology Investment Sustains Moldmaker During Tough Times

When the mold manufacturing industry was affected by the downturn in the economy several years ago, injection mold and die manufacturer Lens Tool and Mould Ltd.

-

Diverse Mold Offerings Sustain Moldmaker, Secures Future Business

Pelco Tool & Mold, Inc. (Glendale Heights, IL)—a producer of close-tolerance, high-quality tools for the closure, food and beverage, personal care, and medical industries—designs and builds a plethora of molds, including, single face and stack, rotating ratchet ring (RRR), conventional unscrewing, strip, side-action, collapsible core, compression, front-loaded core, insert and prototype.

-

Diversity Is Key to Over Six Decades of Moldmaking Success

In 1945, George Carson dreamt of owning his own business. So he founded Carson Tool & Mold (Kennesaw, GA) in his garage, and hired his first employee—George Myers. Carson ran the shop until he retired in 1988 and Myers continued to build the business, passing the reins to his son David, who currently serves as president after purchasing the company in 1996.

-

2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

-

High-Performance Machine Improves Large Automotive Mold Machining

With a new generation of automotive mold applications ahead, the VG is ashowpiece that reflects Hi-Tech Mold's dedication to future innovation.

-

From the Field

Keeping an edge over the competition.

-

Automation: Where to Begin And End

How mold manufacturers are benefitting from today’s automation options.

-

Elite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

-

Gain Access to the Recession-Proof Medical Market

Moldmakers who want to diversify into medical—or maintain their competitive edge—need up-to-date, high-tech engineering and fabrication capabilities in order to meet the toolmaking industry’s most stringent quality standards.

-

Automation Innovations

The use of automation continues to rise as mold manufacturers respond to industry demand of constantly shrinking leadtimes. Manufacturers and suppliers have taken action with better, faster equipment and processes.

-

Technology Partner Is Key to Expanding Moldmaker Capabilities

The past decade has seen significant shifts at R&D Tool, but with a key supplier by its side, they are equipped for new challenges.

-

VMCs Provide Improved Surface Quality for Eyeglass Lens Molds

Carl Zeiss Vision improves crucial surface quality of its polycarbonate eyeglass lens molds and designed repeatability and added capacity into their metal mold operation.

-

A Supplier View on a Decade Of Moldmaking Progress

There has been a tremendous amount of change in the U.S. moldmaking industry over the past 10 years, and mold shops that adopt new machine tools, services and technology will enhance their capabilities for long-term success.

-

Extreme Tool and Engineering, Inc.: Embracing Change

This shop—never content to rest on its laurels—combines lean initiatives and the latest in technology to be a one-stop shop for its customers and win the MoldMaking Technology 2008 Leadtime Leader Award: Small Shop.

-

Complex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

-

Commercial Tool & Die: High Quality and Employee Innovation Drive Success

Unique, employee-developed programs tighten this moldmaker’s leadtimes—resulting in high quality tools delivered on time and the MoldMaking Technology 2008 Leadtime Leader Award: Large Shop.

-

How to Decrease Wire EDM Burn Times

High Energy Applied Technology will produce the accuracy, geometry, speed and surface finish that is required of today’s high quality molds.

-

Solutions for Your Large Mold Machining Challenges

The technology exists to successfully tackle large molds, as long as you acknowledge the problems associated with large mold machining and the machine design features that offer solutions.

-

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

-

Machining/EDM Combo Packs a Powerful Punch

This moldmaker’s new machining center and EDM offer versatility with the ability to machine a number of materials and EDM small holes with ease.

-

Tech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

-

Precision Manufacturing Institute: Specialized Training

This school works hand-in-hand with suppliers and shops—relying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking.

-

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

-

Automation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

-

Moldmakers Counter Offshore Sourcing with State-of-the-Art Capabilities

Advanced engineering and mold building techniques give North American toolmakers entrée to emerging electronics applications.

-

Weldless Technology Eliminates Weld Lines on Molds

A new patent-pending process that eliminates weld/knit/parting lines of molds has been developed by a consortium of alliance partners.

-

Packaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

-

Doubling and Quadrupling Machining Speed, Capacity and Output

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

-

IDEAS, INC.: Good Thinking!

This moldmaker’s decision to venture into the rapid tooling market added up to rapid growth—and the winning of the 2006 Leadtime Leader Honorable Mention: Small Shop for the second year in a row.

-

MSI Mold Builders: Moldmaking Measured and Defined

A combination of lean strategies coupled with niche moldmaking garners this shop the MoldMaking Technology 2006 Leadtime Leader Honorable Mention: Large Shop.

-

It’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

-

How to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

-

Taking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

-

Burning Bright

EDM experts reveal that trends in increased automation combined with unattended machining result in better accuracy and surface finishes in wire and diesinking EDM applications.

-

Making the Transition to High Performance Machining Techniques

Implementing HPM techniques—such as hard milling—into component production can be straightforward with the correct process and other considerations

-

Education/Training

Industry Experts sound off on the value of training, plus a showcase of apprenticeships and grants.

-

Century Die: Forging Ahead

Manufacturing blow molds has kept this moldmaker in the black for more than fifty years-and has earned them an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

-

Machining Variables Influencing High-Performance Wire EDM

While EDM speeds today are impressive, there are a number of machining variables that influence the machining speed of the wire EDM.

-

High-Performance Machining Turns Weeks into Days

Investing in new technology will allow moldmakers to survive and prosper.

-

Advance Tool, Inc. (ATi): Thinking Lean Gets the Green

Boasting clients like Microsoft, Procter & Gamble and Nokia, ATi's customer-driven attitude takes them around the world - and earns them MoldMaking Technology magazine's Leadtime Leader Award.

-

The Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.