Breaking the Mold with Automated Cellular Production

When Precise Tool & Die (Willoughby, OH) was founded in 1969 with one lathe and a Bridgeport, owner Steve Hunyati was worried about competition on the other side of Cleveland. Building a successful mold and die shop that thrived into the ’80s took persistence and vision, and those qualities served the company well even as it saw future competition—and opportunity—grow on the other side of the globe.

In its first two decades of business, Precise Tool & Die was producing mainly die work and injection molds for the automotive and electrical industries with clients such as GE and Packard Electric. While the company was enjoying steady growth, it was also observing changes in the mold and die industry. Frank Corrao, vice president of manufacturing and sales, explains, “Starting in the early to mid-80s, we saw mold and die work starting to head overseas and knew we were going to have to make changes to stay competitive.”

Precise Tool & Die made the decision to move into some production work, not very high volume by industry standards, but what Corrao calls “precision production.” With conservative ownership that requires solid planning, this decision wasn’t made lightly. Over the next two decades, the company changed its philosophy and investment decision to move forward with the transition to production.

“The integration of production capabilities wasn’t an overnight occurrence, but rather a steady transition,” says Corrao. “Within two decades, our machining investments changed from stand-alone vertical machining centers to single-operator work centers featuring three machines, and finally the Makino machining complex [MMC2] featuring the two a61 horizontal machining centers that you see today. As it stands, production orders now represent approximately 75 percent of our business.”

Change in Focus and Philosophy

Precise Tool & Die’s initial steps toward production-oriented work required a delicate balance of preserving its mold and die expertise and business relationships while also demonstrating commitment and resolve toward producing production parts.

“When working with molds and dies, our primary concerns were accuracy, surface finish and fit. However, production requires more emphasis on speed, process and repeatability,” says Corrao. “We knew there were other manufacturers out there that could generate higher throughput than our equipment at the time could handle, so we decided to focus our attention on precision part manufacturing markets such as aerospace and defense.”

One of the early investments Precise Tool & Die made to find this balance was a Makino S56 vertical machining center. “With the S56, we were able to replace two other verticals, improve our quality and still gain additional throughput,” states Al Large, the production manager at Precise Tool & Die.

As the company’s applications continued to diversify, the need for larger work zones became apparent. Rather than searching for independent solutions for both production and mold/die work, Precise Tool & Die began researching technologies that provided enough flexibility to meet the needs for both simultaneously.

“We looked at equipment from all of the major manufacturers, compared all the specs, ran all the numbers, did all the homework and ended with a Makino MCD1816,” says Corrao. “To see what kind of performance was available from this type of machine, we visited Makino’s facility in Mason, OH. The results we saw exceeded our initial expectations. With this machine, we could offer the precision and finishes necessary for our large molds, while also benefiting from the improved productivity of a horizontal machining center platform. It was the perfect solution for the transitional state we were in at the time.”

The trip to Mason not only satisfied Precise Tool & Die’s immediate need for a larger work zone, but also influenced its next phase of production capabilities. While at Makino, Corrao and Large saw a Makino machining complex and instantly recognized its potential for Precise Tool & Die’s production capacity.

Automation Integration

“The capabilities we saw with the MMC2 were inspiring as we looked to continue our expansion of production machining,” says Large. “We knew we needed that type of capability, and the concept of automation would be an easy sell to management with a clear return on investment, but what we didn’t know was how to utilize the equipment to its fullest extent.”

In 2009, Precise Tool & Die purchased an MMC2 featuring 24 pallets, Makino’s MAS-A5 cell controller and two a61 horizontal machining centers. However, the company knew that the equipment itself wasn’t the whole picture.. Based on the company’s previous experience with Makino, significant value was placed on the training and service that came with the investment.

“Makino’s service team has always proven itself valuable, offering fast and reliable support,” says Corrao. “They always make themselves available for even our most simple questions. It’s that level of support that has allowed us to focus on improvements in other aspects of our business.”

Precise Tool & Die quickly learned to leverage its experience as a mold and die manufacturer with the newfound flexibility of the MMC2.

“Serving the mold and die market required the highest achievable quality and innovative processing techniques,” says Corrao. “By carrying that mindset with us into our production work, we gained a leg up on the competition. While many production-oriented manufacturers struggle with tight tolerances in complex 3-D part geometries, we have the skills, expertise and equipment to produce precision parts under tight leadtimes.”

One of the skill sets Precise Tool & Die carried over was the development of custom tooling and fixtures. As it learned from several prior mold and die orders, development of custom equipment may require more upfront time, but the payoff of improved quality and throughput is well worth the wait.

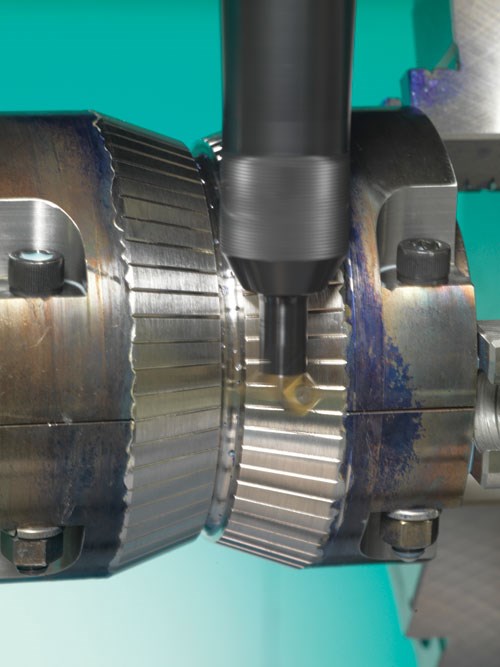

“Our operators don’t have to fidget with parts to get the right alignment. Everything just comes together perfectly,” says Corrao. “Tools are then designed specific to a setup, and with the added benefit of the a61’s 219-tool capacity automatic toolchanger, we can hold an even greater variety of tooling to aid our productivity. By combining these with the flexible scheduling and part management of the MAS-A5 cell controller, we’re able to improve our performance, revolutionize the work flow of our facility and diversify our part varieties.”

Consistent, Accurate Performance

“Precision part production isn’t just an extravagant name for our sales staff to pitch, but a reality through the a61s,” says Corrao. “The accuracies and finishes these machines produce are of such high precision and consistency that we’ve been able to dramatically reduce inspection times for improved work flow efficiency.”

Equipped with a 14,000-rpm spindle and high-pressure through-spindle coolant system, the a61s provide Precise Tool & Die with the speed, cooling and improved chip removal necessary to achieve excellent finishes. Since installation, the company has reduced hand-finishing labor on its mold work by up to 40 percent across the board.

“We are running plus or minus 0.0005, and the Makinos are holding tolerance easily from one run to the next. The repeatability is just there; we don’t have to make any adjustments regardless of material or geometries,” describes Large.

With the MMC2 and its MAS-A5 control system, Precise Tool & Die’s ability to set up fixtures one time without breaking anything down provides additional consistency between part loads. The additional use of broken-tool and spindle-monitoring options prevents broken tools from impacting the flow of production by switching to a spare tool if available or the next job and delivering a message to the operator to replace the tool.

Corrao emphasizes these benefits by stating, “We have no worries about the results we produce. They’re the same today as yesterday, and we’re confident they’ll be the same tomorrow.”

Efficient Workflow

According to Precise Tool & Die, the cellular system has significantly changed the way that materials flow in and out of the shop.

Corrao sums it up this way: “All that’s left of setups is mounting parts and delivering them to their respective storage racks. The fixture is in the pallet stocker permanently, and the tooling is in the machine permanently. We don’t have to give 100-percent first-article inspection before we can start running parts. However, because much of what we produce is complex, precision medical applications, we are required to send each part through our quality lab for final verification. That being said, we rarely see parts come back.”

Precise Tool & Die estimates that it has seen a 40 to 60 percent reduction in cycle times on all jobs moved to the cell. Citing some examples, the company is seeing jobs that once required five operations on a VMC now take only three operations on the a61s, and jobs that previously took three operations currently require only one or two.

“With the a61s, we can complete a part in three operations for a total cycle time of two hours and 20 minutes, where it previously took five operations and seven hours,” states Large. “In extreme cases, the time between casting arrival and finished part is now down to two hours, where it used to be one week.”

At this level of increased throughput, Precise Tool & Die has been able to redeploy eight positions to other areas of the shop floor in order to increase efficiency in other departments.

“The MMC2 has not only improved efficiency within the job orders running on the machines, but workflow as a whole,” says Corrao. “Even jobs that once required outsourcing are now running in the shop, providing us with an even higher return on investment than we originally anticipated.”

New Market Entry

As Precise Tool & Die has developed its production capabilities, it also ventured into the medical industry, servicing parts for CT scanners. One of the primary service components has been a unit inside CT scanners that focuses X-rays for precise imaging. Due to environmental radiation, these parts typically require servicing after frequent use.

The entire assembly comprises more than 100 parts, and Precise Tool & Die uses its arsenal of Makinos to refurbish the units, running 80 of the parts between the a61 cell, MCD1816 and DUO64 wire EDM in order to refurbish the units.

The high speeds and production optimization possible with the Makino machines enables Precise Tool & Die to deliver 30 to 50 refurbished units every week, where the previously contracted shops had serious issues producing the array of necessary parts within quality requirements, much less at the rate the customer specified.

A Road Less Traveled

“If there’s any advice I have to offer other mold and die manufacturers interested in production work, it’s to stay up to date with technology and true to their commitment for quality,” says Corrao. “In a global market, you simply can’t win with old technology or quality that just gets the job done. It takes high-performance machining centers that can provide the perfect blend of speed, flexibility and precision.”

While Precise Tool & Die experienced transitional periods in its move to production, Corrao expresses concern that the competition today doesn’t lend itself to this practice. “Investments in automation aren’t easy to swallow, especially if production isn’t your forte, but it’s a necessity. By partnering with right machine tool provider, the pathway can be navigated much easier for a secure and profitable future.”

Although the performance, flexibility and throughput of the a61s and MMC2 have far exceeded expectations at Precise Tool & Die, it’s the system’s scalability that excites them and drives them forward.

“We were probably conservative with just the two a61s and MMC2, but we’re going to change that,” says Corrao. Precise Tool & Die recognized the scalability of production capacity that is available with the MMC2, and it knows that the only limitation is the business’ ability to invest in the technology to expand the MMC2 quickly and easily for huge increases in production capacity.

For now, the company’s immediate plans are to start by growing the pallet system with an additional 24 pallets to double its current total. Two additional machines equipped with larger tool magazines will also expand the cell. Corrao explains, “Al and I are old school. We never thought we’d see true lights-out operation. It’s just amazing what these machines are capable of producing.”

For More Information:

Precise Tool & Die

(440) 951-9173

precisetoolanddie.com

Related Content

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Using the Internet to Start Your Diversification Strategy

Rather than downsize or give up, one mold shop decided to find new opportunities to apply their skills and equipment, outside of the local moldmaking industry using an online marketplace.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)