Machining Variables Influencing High-Performance Wire EDM

While EDM speeds today are impressive, there are a number of machining variables that influence the machining speed of the wire EDM.

Throughout the past decade, many large and small companies have embraced wire EDM technology as a viable manufacturing process. Today, some EDM manufacturers boast advertised first-pass cutting speeds, using large- diameter coated wires, in excess of forty inch}/hour, which is a far cry from the twelve inch}/hour of the 1980s or the twenty inch}/hour of the early 1990s. In fact, it has been reported that wire EDM machines exceed fifty-two inch}/hour! In order to achieve these rates, a large (.014" O) cable was employed instead of wire, and consumable usage increased by a factor of 3:1.

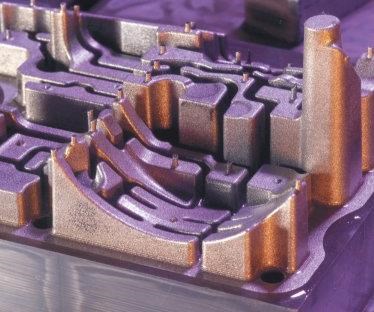

Though there have been improvements in machining rates, the accuracy and precision of the initial (roughing) operation will determine the number of finish skim cuts required to produce a quality part. Logically, as machining speed increases, so does the usage of consumable items and wear parts. Probably more important than the cost of these consumable items used during high-speed machining (HSM), is the resulting maintenance down time they cause. Wire guides and contacts, DI resin and filters are all consumed at a faster rate. Higher maintenance can be expected which also will result in some machine downtime. Although EDM speeds today are impressive, it is not the only factor that has an impact on high-performance wire EDM. There are a number of machining variables that influence the machining speed of the wire EDM.

Factors of EDM

Reliability

Reliability has more impact on machine throughput and productivity than on pure cutting speed. The very nature of the wire EDM and the systems required to control the (wire) cutting tool is critical to machine performance. Higher flushing pressures and premium wires (electrodes) all have had an impact on machine performance and cutting speeds. Faster machining rates result in the need for stiffer, more rigid machine structures and tooling.

Wire Types

The type of wire also will impact overall cost and performance. Standard brass wires are used more than any other wire type by a large-up to 80 percent-margin. What is more important is total time as it relates to part quality! When using standard 0.010" O brass wire you can expect a consistent, reliable wire EDM cutting speed of approximately eighteen to twenty inch}/hour. Unfortunately, the EDM process creates minute chips and debris that can adversely affect the reliability of this transport system. For this reason, a wire EDM machine requires much more maintenance than virtually any other conventional machine tool.

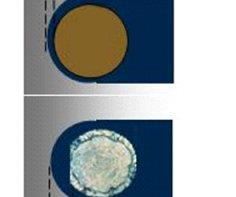

Premium coated wires offer enhanced performance for certain types of applications, overall operating costs caused by higher-wear parts and consumables including contacts, filters, resin and guides all will have an impact on the bottom line. Coated wires will machine faster than uncoated brass. The outer coating melts rapidly cooling the wire and increasing the size of the spark gap, providing better flushing (see Figure 1). Some wires may provide a better finish than brass. Knowing which wire to use for your particular application will help to make you profitable.

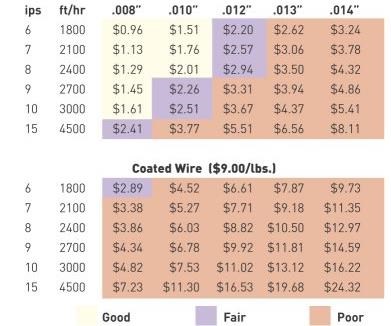

Sold by the pound, EDM wire costs between $3/lb. for brass to $12/lb. for premium wires. Chart 1 gives an example of wire consumption that can be used to calculate operating costs.

It is important to match the correct tool with the application. It is just as important to prevent throwing your money away. Obviously, the earning capacity of a CNC machine tool is more valuable than a few dollars worth of wire, unless of course the wire is simply being wasted. Depending upon the wire being used, the few dollars an hour can translate into thousands of dollars a year.

Wire Guides

There are two types of wire guides used by OEMs on their wire EDM machines. Round or doughnut wire guides are used by a number of EDM manufacturers and can provide a slight advantage when machining larger tapers. A round wire guiding system may help to produce a slight better finish in larger taper angles (greater than 15'). A round guide requires some clearance (~ 0.0002" or greater) in the guide in order to function properly. This clearance is required to thread the wire through the guide.

However, several manufacturers use V-type wire guides on their systems for very specific reasons. One of the biggest advantages to the V-type guide in the EDM environment is the reliability they offer for automatic wire threading. Similar to a precision V-block, V guides provide the accuracy of three-point contact. Though maintenance demands vary widely, the amount of downtime necessary to maintain an AWT system that uses a V-type guiding system is usually less than ten minutes per week. Because of the very nature of the V guide, automatic wire threading is much simpler and more reliable.

Easily cleaned in just a few short minutes, much less time is required to maintain a V-type wire guide. Also, they can be cleaned without being removed from the machine and there is no need for additional cleaning equipment or hardware. Debris from the cut and wire shavings have no effect on a V guide. Lastly, though guide life will vary, V guides tend to provide much longer life and therefore lower per hour cost and downtime. In fact, this type of guide can often provide many years of accurate service.

Maintaining High Precision

Though traditional machining forces are not encountered, wire EDM machines must withstand other forces. For example, the lower head is suspended on the end of an arm that extends from the column. This lower arm must be constructed well to withstand the extreme flushing pressures used during rough machining. Accuracy and surface finishes may be adversely affected as machining speeds increase. Overall downtime replacing worn parts and general upkeep also will increase, not to mention the overall consumption of the wire itself.

When we look at the basic structure of all wire EDMs, it becomes apparent that the location of the wire guides, especially in the lower arm, can be affected by these higher flushing pressures. This can affect wire position in the spark gap. A more rigid mechanical structure is better capable of withstanding higher flushing pressures and may actually help to improve machining speed.

The accuracy of a wire EDM can be affected by the sum of the components that make up the entire system. The CNC control, servo drives and feedback systems obviously are important. But what makes a machine tool accurate? Unfortunately, machine design and construction rarely is a topic of discussion when talking about EDMs. Machine weight, ballscrew diameters and construction are not considered as important. However, machine weight will have a direct impact on the rate at which a machine tool will grow. Regardless of the feedback method, thermal expansion also will have an adverse affect on machining accuracy and even more important, repeatability.

The Key to Real Productivity

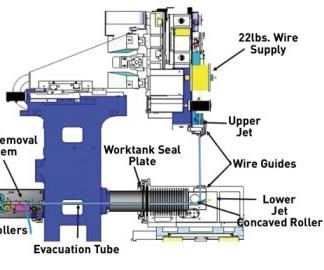

The complexity of the wire transport system and automatic wire threader (AWT) both have a direct impact on performance (see Figure 2). Since the wire used in the wire EDM is small and flexible, no more than two times larger (0.008" to 0.010" O) than a human hair, threading reliably over long periods of time without extensive maintenance has been perceived as a problem. However, the most important feature of a wire EDM machine, in terms of real profitability to the end user, is the AWT-a reliable AWT system can add many hours of available machine time every week, month and year. The AWT makes it possible to schedule work more efficiently on the wire EDM machine based upon the importance rather than the length-time-of cut. Most AWTs use a high-pressure water jet as the main wire transport system between the upper and lower guides. The entire transport system must be maintained according to the manufacturer's recommendations. Wire guide types, the complexity of the jet, the cutting system, drive pulleys and tensioning all have an impact on reliability and performance.

When it becomes possible, depending upon your application, to operate in an unattended environment overnights, weekends and holidays, it is realistic to gain hundreds of machining hours per year. In general, the AWT alone can improve your ROI on a wire machine by 2 to 3:1. In fact, a highly reliable machining system, operating on a continuing basis will outperform a less reliable system cutting at high speed. Failure to properly maintain this valuable machine feature will cause lost production hours and money.

Operator Conveniences

Ease of use and a more friendly user interface has become critical to the user. New Windows-based controls offer many enhanced features that are designed to make the life of the operator easier. New touch screen controls with many built in routines to optimize the wire EDM setup and operation has simplified machine operation and improved reliability, which in turn improves overall throughput. The learning curve also has been reduced dramatically since there are fewer screens that the operator has to learn. Also, this reduces the amount of time necessary for training. On average, these new style CNC controls have improved setup and part processing times by as much as 20 to 30 percent, freeing the operator to perform other tasks.

Taking Advantage of EDM

New machine technology and EDM wires are helping to improve machine performance and, in the right application, cutting speeds, making it possible to produce parts faster than ever before. More accurate control of the wire electrode and various adaptive servo technologies are reducing the number of trim passes required to produce an accurate part.

HSM does not necessarily translate into profitability; it should be evaluated based on the requirements of the application. New EDM opportunities are appearing everyday. Taking advantage of these opportunities will challenge your creativity. It is important to determine for yourself what makes the most sense based on your application's needs.

Related Content

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read MoreRead Next

How to Decrease Wire EDM Burn Times

High Energy Applied Technology will produce the accuracy, geometry, speed and surface finish that is required of today’s high quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More