VIDEO: The Value of Collaborating with Competitors

This story about a palletized HMC offers lessons about more than just technology. It also demonstrates the value of keeping lines of communication open with peers.

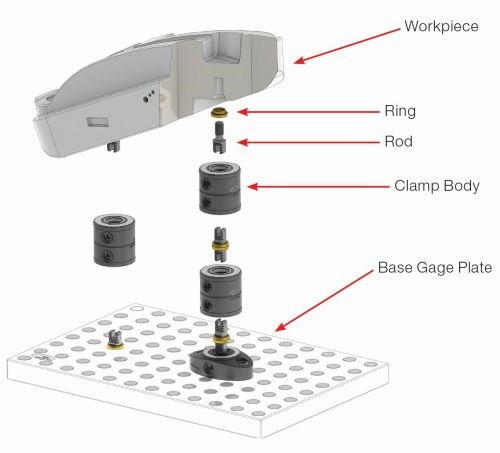

CS Tool Engineering, a mold manufacturer in Cedar Springs, Michigan, credits the addition of a Makino a82 HMC with a pallet changer and modular fixturing system for reducing setup time by half. The shop’s experience demonstrates that such features aren’t useful only for production environments. Streamlining setups can be equally beneficial for a high-mix, low-volume operation like a mold shop, particularly for engineering changes. That story is told in the video above, produced by Makino, as well as this January issue case study.

However, CS Tool’s experience with the a82 offers lessons not just about technology, but also the potential value of working with peers to address common challenges—including workforce development. Consider that the shop might never have been interested in a pallet changer or modular fixturing without seeing these features in action. Notably, operations manager Don Snow says some of the most convincing demonstrations occurred not at any Makino location, nor at the local Single Source Technology (SST) facility that supplied the machine. “It wasn’t until I saw this type of machine in action in other mold shops, and talked with other owners, that I began to see the benefits,” he says.

This sort of thing has become more common lately, says the 25-year veteran of CS Tool. “In the last 10 to 15 years of being in the trade, the relationships with peers and competitors has helped us grow,” he says. “Even though those companies compete with us, they opened up and showed us what they do. That really means a lot.” (Of course, this sort of collaboration goes both ways. For instance, one of the shop’s Tier 1 supplier customers purchased an a82 after seeing CS Tool’s success with it.)

What does all this have to do with workforce development? Snow puts it this way: “As we attract folks into the trade, we also need to mentor them in the trends and future initiatives. This is a changing industry, and to keep up, you must know what your peers in the industry are doing. There is a demand for it.”

Workforce development is a subject that Snow knows a lot about. In fact, his efforts in this area earned him the 2014 “Mold Builder of the Year” award from the American Mold Builders Association (AMBA), and one of those efforts is collaborative by nature. CS Tool is part of the Whitehall Township Tooling Coalition, an alliance of eight Western Michigan companies with a common need for attracting fresh talent to the trade.

That brings me to one final point. I understand why shops might be wary of anything that might shed light on “secret sauce,” particularly when it comes to manufacturing strategies. Still, however, I’m confident that even the most reticent businesses can find common ground somewhere. Workforce development is perhaps the lowest-hanging fruit, but there are plenty of other topics to discuss as well. For instance, as detailed in this article from last year, the OESA Tooling Forum’s discussions tend to revolve around broader, strategic topics like dealing with payment terms of automotive OEMs.

Regardless of the nature of collaboration, I hope that Snow’s comments about shops being more open lately are indicative of a wider trend. One encouraging development is the annual mold shop tour conducted by the AMBA. One business owner who opened his shop up for that event noted that competition is global, and in all likelihood, North American mold manufacturers will rise or fall together in the coming decades. Learning from one another and avoiding making the same mistakes can go a long way toward keeping customers sourcing close to home rather than abroad.

Related Content

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)