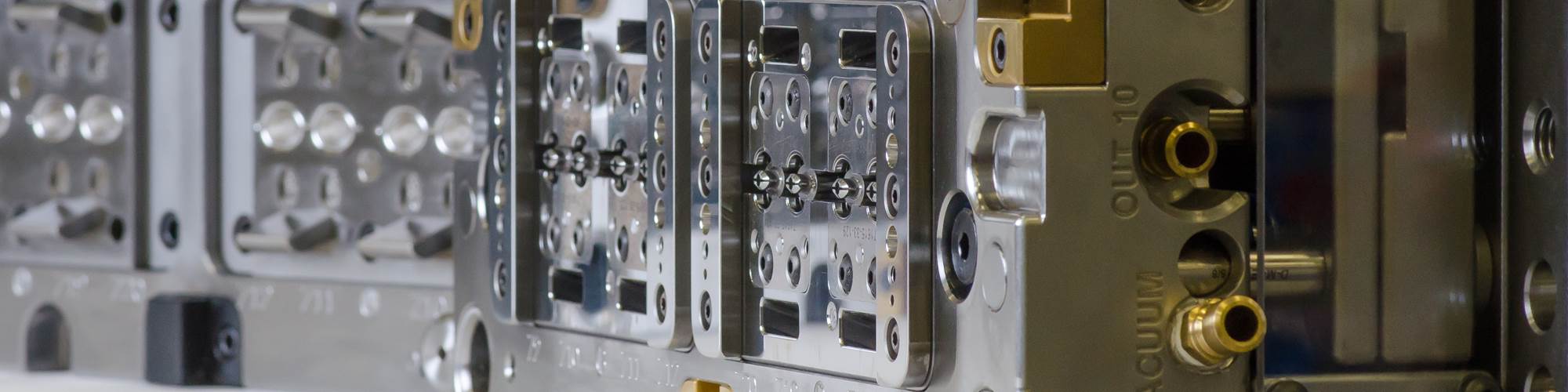

Every detail matters to the Mold-Tech team who takes total care of each mold by using the latest advancements in equipment, project management and training to continually improve quality, productivity and customer service. All Photo Credit: Mold-Tech.

What do you view as Mold-Tech's chief competitive advantage(s)?

Dave Parks, Business Development/Sales: Our people and our manufacturing processes. The key to our success is our highly-trained employees. They are continually looking for new technologies and process improvements to help design and manufacture high-quality molds, such as finding new machine tools for automating our grinding area, which has led to a reduction in the time required to grind cavity and core components.

They also have helped with the development and communication component of our new sinker EDM cell. This effort entailed the transfer of scanned data from RFID chips mounted on the electrode holders to the sinker EDM cell, the communication between the 3R robot that loads pallets of cavity and core components into the sinkers and loading the correct electrodes to correspond with the correct cavity and core components to complete the process. Also, people who run machines do their own programming, and we use horizontal machining centers for our pre-heat treat steel process.

Explain Mold-Tech's training approach.

Parks: Mold-Tech develops each employee through hands-on training with an organized one-on-one approach. Matching an employee with a designated trainer allows for constant and thorough feedback during the training process.

This training method is used for existing employee skills as well as incoming interns. Also, we focus on cross-training employees across various departments to allow for flexibility in production and employee growth. Cross-training also facilitates sharing ideas across departments as well as suggestions for process improvements and efficiencies.

Design for manufacturing, design control, in-house mold-flow analysis and regular comprehensive design reviews ensure an optimal mold design.

What is your most valuable asset?

Parks: Our entire team from conception to final assembly. Their experience and knowledge is the cornerstone of our business. We have extensive technical expertise and use an engineering-driven process. Our thorough production planning and tracking help us keep our projects on schedule with on-time delivery. We also use One Note for recording build plans and for tracking build progress.

Generally, the process is as follows: Most of our quotes start with a 3D design concept. Once we receive a purchase order, the project manager shares the concept with the engineering group.

We also put additional value into the design. For example, we apply a color-coding scheme to each component. This step helps communicate the overall build plan and brings value to the entire group involved with the project. Most of our staff, from project managers to sales and design, have a toolmaking background.

Then our highly-skilled moldmakers coordinate each job with the various departments to ensure a successful mold build. Once we complete the production planning meeting, the lead toolmaker then coordinates with each department, sharing the build plan and timeline. Every department keeps a separate schedule, which is connected to the overall schedule.

Our experienced staff is also dedicated to product quality and customer service, including project managers who maintain effective communication throughout the entire operation. A project manager is the single point of contact for our customers, from initial request for quotation (RFQ) to tool shipments. They are involved when we receive the purchase order, to the design, and kick-off meetings, up through the production planning meeting to ensure we meet our customer's needs.

They also provide weekly updates to our customers on their projects' status from the weekly project reports completed by the lead toolmakers. Our customers view the project managers as an extension of their engineering departments.

Mold-Tech continually invests in equipment and highly automated systems to produce consistent, highly accurate results in less time. For example, ultra-precise hard milling, electrode manufacturing and EDM machines, as well as precision fixturing and palletization.

What is your latest technology focus?

Parks: We invest continuously in new technology. Each department is being evaluated for automation opportunities to increase throughput and decrease bottlenecks. We have focused on adding automation through the use of robots in many of our new machining centers. Along with robots, we have added pallets to allow our machines with robots to maximize machine run time.

Take us through the automation in the shop.

Parks: We've expanded our automation capabilities in many areas and have invested millions in new equipment over the last several years. For example:

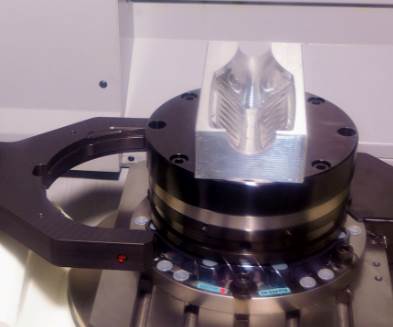

- A sinker EDM cell with two Makino EDAF3 sinker EDMs, and a 3R robot that has a 200-position electrode carousel and a 20-position carousel for pallets that hold cavity and core components.

- Makino 5-axis graphite mill with a 60-position 3R robot.

- Two Makino 3-axis graphite mills with 60-position 3R robots.

- Two Makino hard mills with 20-position 3R robots.

- Two Makino A51 horizontal machines with rotating tombstones permit machining on multiple sides of one block, improving throughput time.

- We have implemented palletizing to streamline efficiencies within the different manufacturing areas.

What is the impact of automation on your workforce?

Parks: More CNC machines are helping us remove manual labor. Over time, we have transformed our workforce from one with a heavy reliance on manual labor to one using automation to drive manufacturing.

Our workforce has also increased. We currently have 60 employees, and we still need more people to help with the setup and programming to run all of the automation.

To solve this, we work with a couple of technical colleges and one local high school to promote moldmaking and to find new young talent. We give tours each year of our shop and usually get a few people from these events interested in Mold-Tech who return to inquire further. Over the last several years, we have offered technical internships at both the college and high school levels. All of our interns have returned after completing school to begin employment with us.

Our workforce has increased. We still need more people to help with the setup and programming to run all of the automation.

How does Mold-Tech define quality?

Parks: Our quality systems are an integral part of our manufacturing process with document-controlled processes. Quality control is found throughout the entire moldmaking process.

Our quality lab is a climate-controlled environment with dedicated personnel. Our capabilities allow us to measure everything from simple parts to the most complex components and features. The lab is equipped with an OGP SmartScope Flash 500 with ZONE3 Pro metrology software, an Accucentric auto-calibrating zoom lens, scanning probe and touch probe and an MTR rotary indexer. We also have a Hexagon Global Perf 575 coordinate measuring machine, and a Hexagon Global S Blue 5.5.5 coordinate measuring machine with Leitz LSP-X1C quill mounted scanning probes.

Furthermore, we have simplified our inspection operations with software that extracts part data directly from CAD models assuring maximum accuracy. We even use PC-DMIS software for inspection that allows us to share that data with our customers efficiently.

In-house mold sampling is much more than just molding parts. Mold-Tech's RJG Master Molder-certified staff are molding professionals, trained in the most advanced techniques and equipped with in-house eDART capabilities to visualize and quickly optimize your mold’s performance.

Any additional value-added services?

Parks: Mold-Tech focuses on production-ready molds, and making our in-house sampling a value-added service. This offering allows us to make any necessary mold adjustments quickly and efficiently. We have three dedicated engineers to facilitate sampling, including the use of scientific molding processes.

We also do mold repair. Our in-house laser welding technicians create precise welds with minimal downtime for our customers. This process is useful when completing modifications, revisions and repairs. With a dedicated staff and in-house laser welding, we address customer needs on a timely basis.

We also build mold bases in-house, provide in-house mold polishing services, and we engrave or laser mark our mold components for easy identification and service.

Additionally, we offer end-of-arm tooling for total mold integration. Our team designs end-of-arm tooling to suit our customer's needs for the handling of parts and runners.

Related Content

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreTechnology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreAchieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read MoreRead Next

Diversification and Departmentalization Drive Growth for Wisconsin Mold Builder

New ownership at Innovation Mold & Design (IMD) grows the company by investment in technology that serves a departmentalization and diversification, business model.

Read MoreA Blueprint for Die-Mold Shop Automation

An increasing number of mold and die makers are considering automation to get better utilization of their equipment and skilled people. While it will take good planning and execution, there is a manageable path to automation that will bring efficiencies to tool shops in ways hardly imaginable only a few years ago.

Read MoreTips for Selling the Value of Automation

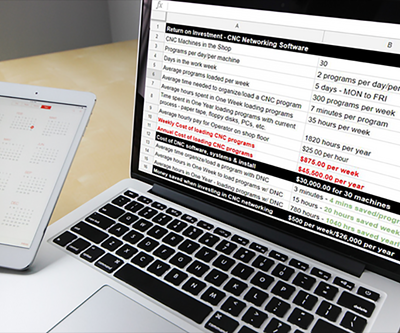

How to prove automation saves time on the shop floor.

Read More