Do You Make a Lasting Impression on Customers... and Youth?

Cavalier Tool and Manufacturing Ltd. (Ontario, Canada) is one mold manufacturing company that likes to leave a lasting impression.

Cavalier Tool and Manufacturing Ltd. (Ontario, Canada) is one mold manufacturing company that likes to leave a lasting impression. It’s not accomplished just by showing customers the company’s extensive facility filled with advanced technologies and standardized processes (though these characteristics helped them win MMT’s 2015 Leadtime Leader Award). It’s also a matter of showing them (along with students, their instructors and parents) the personality, or culture, of the company. It’s very people-centric and driven for success.

I had the privilege of touring Cavalier Tool a couple of weeks ago with my MMT colleague and editorial director, Christina Fuges. As we took in the many scenes from department to department it was clear the company was focused on its people and providing them with the tools they need to succeed. I’m referring to efficiency-building features, like adding wheels to every saw-horse to enable faster movement of tooling across buildings, and installing cranes in such a way that molds can “hop-scotch” over other workstations without disrupting anyone’s work or having to transfer the large tools from one crane or table to another. Cavalier Tool also developed a system for collecting and selling (for scrap) the tons of metal chips its machine tools produce each day. The system collects the chips and compresses them into hockey-puck-sized metal disks, which economizes on bin space and helps keep the floors cleaner. I could go on, because Brian Bendig, president, never stops searching for ways to push the envelope on building efficiencies in his plant. “I don’t give my guys any excuse for not getting a job done right and on time,” he says. Bendig also mentioned that MFG Day is a big deal at Cavalier. “One of the biggest local events is Manufacturing Day,” he says. “We love hosting tours of our company year-round, in fact.”

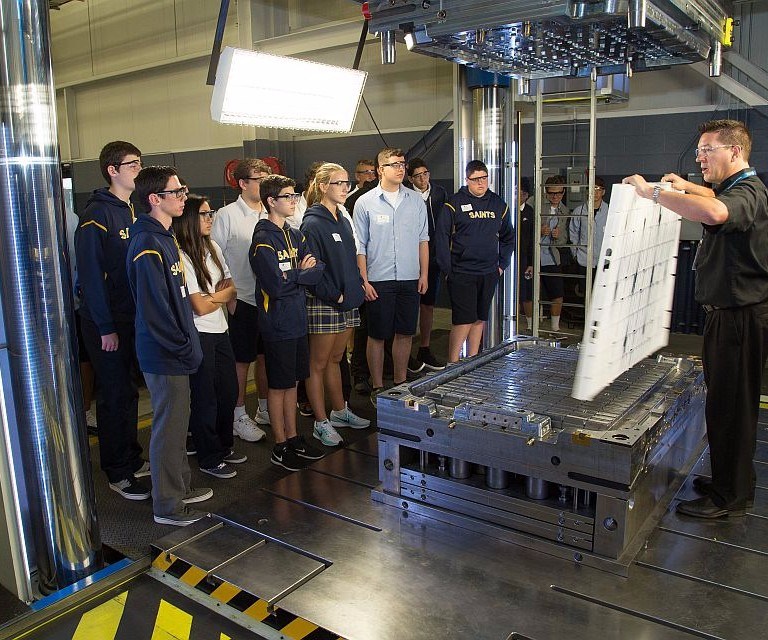

In recognition of MFG Day, Cavalier hosted more than 200 students and educators from Belle River High School, St. Anne’s High School, Westview Freedom Academy, and Maryvale to tour its facility, so they could gain a deeper understanding of the careers available within our industry. In the spotlight were the many high-tech machines, like the OPS Ingersoll Productions Systems Eagle 1200 sinker EDM machines and Gantry Eagle 1400 sinker EDM, the impressive array of CNC machining centers including several Makino (MCC 2013 VG HMC, A92 dual-pallet HMC, A82 dual-pallet HMC, V99L_50 VMCs (2), F9 VMC, F5 VMC), a DMG MORI NH 400 DCG HMC with pallet changer an Okuma America Corporation Geno M560-V VMC, a Hermle Machine Company C62U Dynamic five-axis HMC and an OPS Ingersoll Eagle V9 five-axis machining center. “Every year we challenge ourselves to outdo the previous year, creating different interactions to keep the students interested,” Bendig says. “We have informative videos for them to understand the process that goes into making a mold, plastic resin samples in various colors to encourage them to think about what have they seen manufactured in these colors. We also had a mold running and we set up our Millutensil spotting press to make small wax parts.”

Lasting Impressions

Lori Kennedy, who works in the human resources department at Cavalier, shared a couple of stories related to past MFG Day events that left some lasting impressions.

“I recently covered orientation for our HR department for an employee’s first day. After introduction and learning a bit of history on the employee, I learned he had been to our facility in the past and he remember me from giving his school a tour in the past,” Kennedy says. “He said enjoyed learning about us then, and reached out to us when he was ready for employment because of the impression we made on him.

“Tim Galbraith, our sales manager, also shared a great story with me,” she continues. “He led a tour for Manufacturing Day a few years ago and a mother and daughter both attended. Very recently, Tim bumped into the mother and she shared the effects of our tour. Manufacturing Day helped pave the way for her daughter, as she selected a career in the skilled trades and is now a welder.”

How do you leave a lasting impression? We all know it’s important to impress customers who visit our plants, but when youngsters visit, be it during a MFG Day event or other occasion, do you strive to engage them both visually and cerebrally? Tell us about it! Contribute to this blog discussion, or ask a few questions, share some thoughts and suggestions.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)