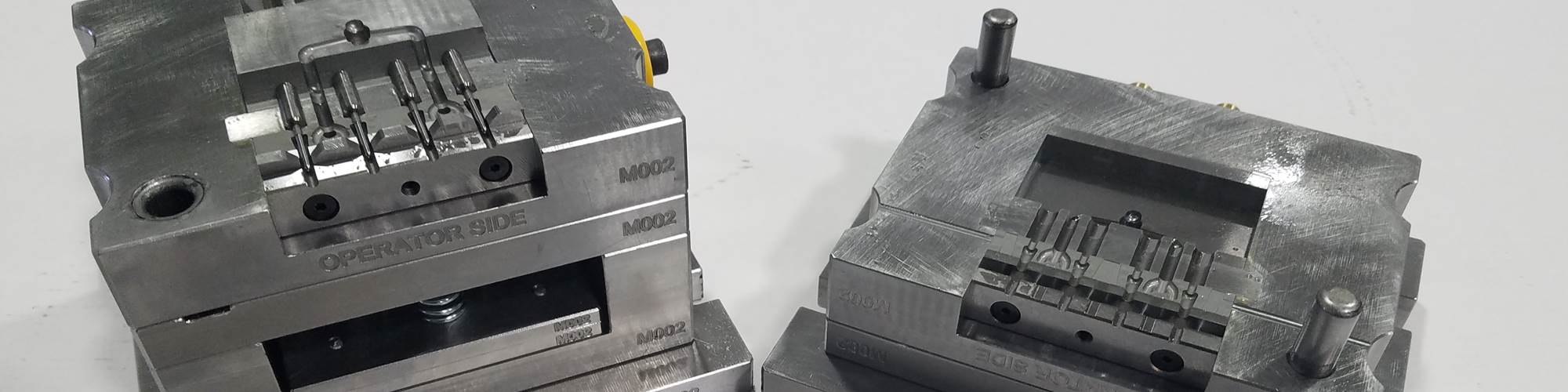

Prodigy Mold & Tool is a team of problem solvers with experience in engineering, manufacturing, quality and attention to detail. Photo Credit, all images: Prodigy Mold & Tool Inc.

Who is Prodigy Mold and Tool?

Steve Hack, Business Development Manager: Prodigy Mold & Tool is located in Haubstadt, Indiana. We celebrated our 25th anniversary last July 2021. Our shop is 15,000 square feet with state-of-the-art technology, including purchasing five new machines within the last year and a half.

Prodigy Mold & Tool is a full-service injection mold manufacturer of new tooling and molded components for its direct customers and other mold manufacturing companies.

We have 30 highly skilled and dedicated team members with more than 500 years of combined mold building experience. We specialize in demanding applications for the automotive, medical, motion control, safety and security, electronics and consumer goods industries, including precision gears, unscrewing, medical cleanroom, complex multi-action and high-cavitation hot runner molds.

Prodigy Mold & Tool is a full-service injection mold manufacturer of new tooling and molded components for our direct customers and other mold manufacturing companies. Prodigy’s experienced moldmakers are highly skilled in performing engineering changes, preventative maintenance and mold repair. We strive to combine traditional craftsmanship with state-of-the-art technology to design and manufacture the highest quality injection mold tooling.

The Prodigy Mold & Tool team is dedicated to solving complex problems by engaging early in product development.

We are problem solvers. Our experience in engineering, manufacturing, quality and attention to detail provides us with the tools to solve our customers’ complex problems. As a result, our customers can count on their molds being worked on by team members who take pride in their craft from start to finish.

What do you view as your chief competitive advantage?

Hack: We excel at solving complex problems and prefer to engage within the early stages of product development. Our design process starts as soon as the order is received. We collaborate with our customers from the beginning on part design, quality requirements, cost reduction ideas and design for manufacturability (DFM). We immediately focus on addressing gating, cooling, venting and mold processing optimization to manufacture a mold that will produce a repeatable process and a consistent, dimensionally stable part.

We are always looking for the latest equipment and technology that gives us a competitive edge in reducing cost and manufacturing lead times for our customers.

What is your role at Prodigy?

Prodigy Mold & Tool manufactures precision gears, unscrewing, medical cleanroom, complex multi-action and high-cavitation hot runner molds.

Hack: I have more than 25 years of experience in sales and business development in various industries and am excited to bring that experience to the mold and tool industry. After completing my degree in Tool and Die Design, I began my career working for a Tier 1 company designing water pump housings for the automotive industry, where I immediately got a crash course in meeting challenging deadlines and realizing the importance of attention to detail. Then I decided to pursue a career in sales and business development, which has allowed me to develop programs to streamline processes and reduce day-to-day challenges.

Prodigy Mold & Tool specializes in demanding automotive, medical, motion control, safety and security, electronics and consumer goods applications.

I have been with Prodigy Mold & Tool for almost three years in the position of business development manager, which was created right before I came on board. I work directly with the customer’s senior management team, purchasing departments, engineers, quality assurance and sales departments to ensure unsurpassed customer service, including on-time delivery of quality products and impeccable communication throughout the process and beyond.

What is Prodigy's most recent technology investment?

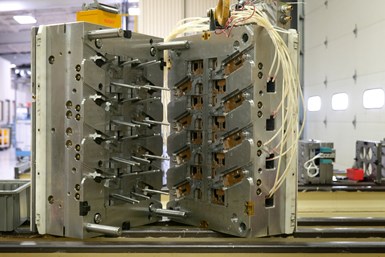

Hack: In the past two years, we have added five new machines with a cost of over $1.5 million, drastically improving our machining capabilities and adding to our competitive edge:

- Okuma MV460 five-axis.

Prodigy Mold houses an Okuma MV460 five-axis and an MB-66V hard mill.

- Okuma MB-66V hard mill.

- Makino EDAF3 sinker that shares an Erowa 196-position ERC 80 robot with our Makino EDNC 6.

- Makino U3 wire EDM with available wire down to 0.004 millimeters.

- Roeders RXP501 three-axis machine with an RCS2 Robot — very compact and flexible automation that can automate two machines.

- Cimatron CAD/CAM (three designer seats, five N/C seats and 11 viewers seats).

- ESPRIT software for our wire EDM machines.

How has leadership changed its general approach to business?

Hack: In September 2021, we started the process of getting ISO9001:2015 certified and received our certification in December 2021. Our customers are becoming more and more demanding when it comes to their vendors having a robust quality operating system. Our thought process was two-fold. First, we had a customer encouraging us to become certified. We believed the time was right to improve our quality systems and processes, knowing it would help take us to another level in our quest for excellence. Any company that has been through the certification process knows that achieving ISO 9001 certification is demanding.

Makino EDAF3 sinker sharing an Erowa 196-position ERC 80 robot with a Makino EDNC 6.

Each team member in our organization must be wholly dedicated to pursuing excellence in everything they do. By scrutinizing our enterprise at every level, we assure our customers receive superior customer service and the highest quality products. In addition, the process pushed us to start thinking more strategically about objectives to track and improve. It all begins with a disciplined approach to following our processes, tracking goals and objectives and hitting our KPIs. Achieving this requires a high level of accountability from everyone in the organization, creating standard operating procedures, and using them for new team members and as a baseline for continuous improvement.

The Leadership Team needed a fresh perspective on how to grow Prodigy to the next level, so we all read Traction by Gino Wickman, which is essentially “a blueprint for businesses that are stuck at a point where hard work and determination are no longer enough for them to survive and grow.” Wickman is a business owner and consultant who shares a step-by-step guide for structuring a business using his Entrepreneurial Operating System (based on practical experience) to remove typical frustrations.

As a result, we recently hired a general manager/integrator to take over the daily duties that were bogging down and preventing owner Darrin Schmitt from focusing on being the visionary who will lead us in the right direction with technology and new customer growth. The term “Integrator” is defined in Traction as the person who will collaborate with the visionary.

Let's talk sales and marketing.

Hack: We recently revamped our website which offers a more in-depth look into the shop, a portfolio page and a new company video. We are also ramping up our activity on social media, mainly LinkedIn and YouTube. We find it effective to post videos and images of our team’s work. We have received positive feedback from current and prospective customers that these videos help show our capabilities. In today’s day and age, it isn’t easy to get a customer to come in for a visit so they can see things in real time. This new way of life makes having an effective and current social media platform critical to creating more customer traffic and opportunities.

For example, I’ll feature a short video highlighting the type of work the team in the toolroom does, like assembling a 4+4 rotary side insert shuttle tool on a Friday afternoon, or a project with electrodes cut with a 0.3-millimeter end mill.

Prodigy is always looking for customers who value partnership. We are developing a sales strategy to aggressively search for and add new clients who understand our capabilities and the value of our expertise that will help them through their projects, from initial talks to (DFM) design for manufacturability.

What are the most significant ways you expect your business to evolve in the next three to five years?

Hack: Prodigy is always looking for customers who value partnership. We are developing a sales strategy to aggressively search for and add new clients who understand our capabilities and the value of our expertise that will help them through their projects, from initial talks to DFM.

We will continue to focus on cross-training and team member development to prepare our next generation of highly skilled moldmakers, CNC machinists and designers. We will also continue to focus on growth and expansion by researching and investing in new technology and automation. Advanced technology will allow us to branch out into other markets besides our core business, the medical and automotive industries.

Darrin is committed to upgrading our current equipment and investing in new technology if a need is present. In addition, Indiana has a great non-profit organization called Conexus, which is a robust network of industry, education and public-sector leaders working to strengthen Indiana’s competitive advantage in advanced manufacturing and logistics (AML). Right now, they have more than 250 partners. They leverage innovation and technology and address the most pressing talent needs to make AML more productive and profitable by offering grants up to $200,000.

We recently were awarded a $160,000 grant to help implement an advanced machining platform that involves an integrated robotic transfer system to improve our production capabilities. We put the funds towards our investment in a Roeders RXP501 three-axis machine and an RCS2 robot. That purchase was right around $520,000.

Roeders RXP501 three-axis machine with an RCS2 Robot.

Tell us how you are addressing the skills gap in the industry?

Hack: We work with Southern Indiana Career & Technical Center’s (SICTC) Precision Machine Program. We have also worked with the American Mold Builders Association (AMBA) to provide SICTC with two grants to date for $15,000 used to update the CNC machining area with two upgraded computerized vertical milling machines and the purchase of new seats of CAM software.

We’ve had some interns who have decided to come to work for us full time after completing their classes. It’s interesting to watch how quickly the younger guys and gals pick up the technology and instructions on how to run the new equipment.

Our 30 employees range from 18 years old to 65 years old. We try to motivate our younger team members to take the initiative to want to learn more and do more. We expose them to all areas of the facility to see where the best fit is and allow them to provide feedback on where they are comfortable. For example, one of our newest team members was an apprentice in the technical school program and worked in different areas of the facility. He ended up settling in the EDM Department after taking the initiative to try and learn as much about all the areas so he could make an educated decision on his path forward. We had an opening in the EDM Department and he jumped at the opportunity.

He now runs five sinker EDM machines with little supervision. He has expressed interest in becoming a moldmaker, so the cycle will continue with training his replacement as he moves on to what interests him. Having buy-in from our new team members is paramount to developing the organization's future talent.

Describe the most interesting/notable mold project your company was awarded.

Hack: One of our newer customers in automotive asked us to make a 4+4 rotary side insert shuttle tool for electronic overmolded components. This mold wasn’t your everyday tool as it was made up of 968 purchased components, 179 purchased/altered components and 382 custom-built components in-house, so a total of 1,529 total components. Did I mention that we built four of these tools, each with an extra bottom half? We had carts and carts of components all over the shop.

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

Current Technology and Trends in a Micro Molding Tooling Center

Contract manufacturer of medical micro components and finished devices discusses current trends and challenges with micro molds—micro milling, cutting tools, mold coatings, CAD/CAM, micro welding, mold design, micro molding, validation, automated assembly and training.

Read MoreThermoset Mold Builder Takes on EV Market

New Dynamics and NDC International provide complete tooling and molding solutions for the electric vehicle market and electronic encapsulation technology.

Read MoreStrategically Located Mold Builder Offers Precise Tooling and Molding

This small family-owned U.S./Mexico mold builder moved to the next level of precision with next-generation technology investment.

Read More