Packaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

An array of equipment and materials enables moldmakers to produce tooling systems for packaging that combine product performance with process economy. From new grades of metal to the use of high-speed machining centers and components that provide flexible production capabilities, moldmakers are zeroing in on these products to squeeze every cent of profit from a market where margins are low and under constant pressure.

The route to increased competitiveness and profitability in packaging isn’t through the use of inexpensive molds, suppliers argue, but with advanced design features that make tooling more productive. “Now more than ever, the demands on packaging molds are for these tools to run cleaner, faster and with more predictable performance and maintenance practices,” says Glenn Starkey, President of Progressive Components (Wauconda, IL).

Key objectives in the effort to improve the efficiency and economy of packaging molds include reducing the time it takes to build a tool and engineering molds for greater productivity. “The economics come with decreases in cycle times,” notes Martin Baumann, Business Development and Marketing Manager for Husky Injection Molding Systems (Milton, VT). “The faster you produce parts, the more you drive costs down.”

Also important is minimizing or eliminating post-mold handling of products. Moldmakers are achieving this through greater use of in-mold finishing and assembly operations, and by designing molds that optimize process automation. Being able to use a robot to demold parts, stack and package them speeds downstream processes and reduces the cost of labor. “Automation is key from a mold-building point of view,” Baumann adds.

Combining productivity and automation in a mold gives a packaging producer a formidable means of offsetting costs, especially when it comes to dealing with the continuing escalation of resin prices. “These are among the steps a molder in North America can take to compete globally,” says Tim McCulley, General Manager of Accurate Mould Co. (Rexdale, ON), a division of Wentworth Technologies (Burlington, ON).

Upgrading Your Process Capabilities Via Technology to Compete

Machining

One area where moldmakers are looking to upgrade process capabilities is machining. A number of companies offer equipment that’s designed to dramatically reduce build times through such features as high machining speeds and improved finishing capabilities.

Makino (Mason, OH) plans to introduce this fall the V99 vertical milling machine, an addition to its V series machining centers. The V99 will have a larger work area than the V77, Makino’s current size leader, according to Marketing Manager Mark Rentschler. The work zone of the new model will feature travel distances of 1500 mm in the X axis, 1000 mm in the Y axis and 800 mm in the Z axis. The V77, by contrast, has travel distances of 1200 (X) by 700 (Y) by 650 (Z) mm. Based on the V99’s travel specs, it should handle workpieces with dimensions of around 59 by 39 by 31 in. The V77 accommodates workpieces of 55.1 by 27.6 by 21.7 in.

“This machine will permit larger molds and mold plates to be cut with high degrees of accuracy and speed,” says Rentschler. The V99 will be equipped with Makino’s proprietary SGI.4 (super geometric intelligence) control that permits high definition milling of complex shapes at high speeds. The SGI.4, which is tuned to Makino’s servo technology and machine design, can reportedly reduce mold milling time by an average 15 percent and by up to 30 percent in some applications. The SGI.4 control also cuts down or eliminates hand polishing of some tools.

Performance details about the V99 haven’t been released, but features of the V77 include spindle speed of 12,000 rpm, cutting and traverse rates of 787 ipm and 5-s tool-swap time. It has a table-weight capacity of 5,500 lb. Rentshcler says one packaging producer, thermoformer Prent Corp. (Janesville, WI), has used an earlier control, the SGI.3, with the V77 and another vertical machining center, the S56, to reduce some milling operations to six hours from an average of 23 hours.

Another supplier with a new vertical machining center is Haas Automation (Oxnard, CA). The VM-6 machines relatively large molds, making fast cuts and contours with a 12,000-rpm spindle, says Bob Burrows, Sales Product Manager for vertical machining centers. The model has a 64- by 28-in work table, which is not only drilled and tapped but precision-bored for dowel pins and equipped with T-slots in X and Y directions. The VM-6 has travel of 64 (X) by 32 (Y) by 30 (Z) in, and feedrates of 540 (X) by 600 (Y) by 600 (Z) ipm. Table-weight capacity is 4,000 lb. The VM-6 also features a power-failure detection module that shuts down the servo controls when it detects a power outage to prevent mold damage.

To reduce heat and maintain thermal stability, the unit uses an inline, direct-drive spindle. Burrows says that with this configuration there is no need for a spindle chiller, which adds an extra component. The VM-6 also controls heat by circulating coolant through the head. The model can be equipped with 18- and 24,000-rpm direct-drive spindles, as well as a 30,000-rpm version, though this option requires a belt drive and conventional heat-containing components.

One machining center designed for high-speed work is the Johnford SHV-1000, manufactured by Roundtop Machinery Industries Co. (Taiwan), and distributed by Absolute Machine Tools (Lorain, OH). The unit, which Applications Engineer Jerry Hill says is the fastest Absolute offers, achieves cutting speeds of 787 ipm. It is a true C-frame machine with linear ways on all axes for rigidity and precision. The Y axis utilizes four ways for accuracy, and the Z axis has a ram-type head that operates without a counterbalance for fast acceleration and smooth cutting.

A 24,000-rpm spindle is standard, and a 50,000-rpm version is optional. The SHV-1000 utilizes Cam-Tool CNC software (distributed by CGS North America, Inc., Oldcastle, ON) that Hill says provides benefits in such areas as torchoidal roughing and high-quality finishing. The machining center has been used to build commodity molds profitably for cost-sensitive applications like thinwall seed containers for garden shops.

Another unit designed to reduce process time is the Super Mold Maker 2500µ from Mazak Corp. (Florence, KY). Engineered for complex molds, it combines speed with high-precision machining and has outstanding finishing capabilities. In many cases it cuts molds accurately enough that hand-polishing isn’t required. The Super Mold Maker utilizes a 25,000-rpm spindle with three-phase balancing that holds vibration to as little as 0.000059 inches. The machine is designed to maintain a high degree of rigidity, and uses linear guides and a large inertia motor to control servo accuracy and keep interpolation variance to less than a micron.

Table dimensions are 47.2 by 22 in. Travel distances are 40.1 (X) by 22 (Y) by 18.1 (Z) in. The machine has a 30-tool magazine that’s expandable to 40 tools, and does a tool swap in as little as 0.8 seconds.

Fast, accurate machining benefits a program from Accurate Mould. Called “Fast to Market Tooling,” the company will build production molds for select parts in two to four weeks. McCulley says these molds are for customers who need to get large numbers of new product samples to distributors but don’t want prototype-quality parts. Cavitation is limited, but otherwise molds are the same as production tooling, he says. They run automatically and use no hand-loaded inserts.

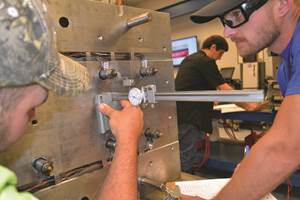

Components

Once the cutting is done, moldmakers look for components that assure accurate and repeatable processing while minimizing downtime due to maintenance and repair. A number of suppliers are developing parts that not only meet these needs, but serve as economical alternatives to components that moldmakers previously engineered themselves.

D-M-E Co. (Madison Heights, MI), for example, introduced at NPE in June a pre-engineered centering device for stack molds that’s sold off-the-shelf and designed as a drop-in replacement for similar components that are custom made. According to Chuck Azzopardi, Product Manager for Mold Components, the device utilizes a helical gear shaft and two nuts. It translates the motion of a stack mold as it opens and closes into a centering action that assures alignment. The device, called a two-stage ejector and lifter system, is for use with two-level stack molds, but Azzopardi says multiple devices can be ganged together for a four-level stack mold. D-M-E provides design guidelines for installation. Moldmakers generally need to drill and tap in the mounting screws and drill and ream the positioning dowels. The component, made by D-M-E in Germany, is reportedly less expensive to buy than it would be for a mold builder to make.

Progressive Components also is expanding its line of off-the-shelf parts. Recent products, primarily for cap and closure molds, include collapsible cores. Starkey says that the ability of moldmakers to order finished cores with undercuts helps them meet delivery deadlines. The cores can also eliminate the need to add long gear racks for unscrewing actions, thus reducing cycle times.

The value of off-the-shelf components is being extended to an innovative multicomponent molding concept—the Spin Stack mold, developed by Gram Technology (Scottsdale, AZ). Spin Stack utilizes horizontally rotating mold segments to fabricate parts and complete in-mold operations like overmolding, insert molding, labeling and decorating, painting and assembly. In packaging, especially, the technique provides benefits of productivity, reduced secondary operations and economy, according to Gram Technology President Jes Gram. Moreover, because Spin Stack molds utilize a greater percentage of their molding area than conventional molds, they can be used in smaller-tonnage injection machines with no tradeoff in productivity. Progressive is developing a standardized mold component package for Spin Stack molds.

Stack molds are a growing option for molders looking to maximize productivity and profitability, especially with ultralow-margin parts like lids, closures and dairy containers. Izon Industries (Brampton, ON), which also is a division of Wentworth Technologies, has developed a quick-change system that reduces downtime and increases the process flexibility of four-level stack molds. Mario Giansante, General Manager, says the design relies on a mainframe and two sets of inserts, and on special air, water and electric connections that don’t need to be unplugged during changeovers.

The utilities are connected to the mainframe of each mold and remain in place during operations. Each mainframe has two modular mounting plates—a core and a cavity side. When a processor wants to change molds, he only needs to unbolt and remove the modular plates and replace them through the front of the mold with a different set. “There’s no need to shut off the heat, drain the water or wait for the heat to come up to temperature again,” says Giansante. Conventional stack molds can take a half-day to change, he notes. Customers say these stack molds—some are 62 inches tall and 44 inches wide—can be changed over in less than an hour.

Hot Runners

Stack molds also influenced one of two component introductions Husky unveiled at NPE. The Split Sprue Bar, for 2-, 3- and 4-level stack molds, provides full mold access without the obstructions common with full sprue bars. The Ultra Packaging Nozzle is for use in hot runners exposed to the high injection pressures of thinwall packaging.

The Split Sprue Bar improves robotic part removal, especially with thinwall containers (down to 0.3 mm). Baumann says that robots remove parts faster than gravity drops and thus reduce cycle times. Robots also can stack parts in containers for shipping—eliminating the need for this to be done by workers. “With the cycle times that are required these days, you have to have a robot,” he remarks. “If you have a robot, you have to have accessibility to the molding surface. The Split Sprue Bar facilitates this.”

The Ultra Packaging Nozzle, meanwhile, was designed to withstand 35,000 psi. “Other suppliers don’t publicize their numbers,” Baumann says, “but we are in the upper segment of the market, for sure.” A robust nozzle is more important than ever, because as packagers continue to reduce wall thickness, injection pressures rise. “The entire system has to keep up with this,” Baumann remarks. The nozzle is designed to be leak-proof, and comes with a three-year guarantee. The tip can also be easily removed for fast replacement of the heaters.

One feature of the nozzle is the Ultra Flow Tip, which Baumann says has a mixing function that speeds up color change. When producing parts like closures, frequent color changes are necessary. The tip mixes the residue of a color that remains in the nozzle in such a way that it’s concealed under the incoming shot of a new color, hiding it from sight in the molding. Baumann claims this can yield up to 50 percent faster color change and increase throughput by as much as 30 percent since there is less scrap. The Ultra Flow Tip is not brand new—it was introduced at NPE 2003—but has been upgraded.

Another specialist in nozzle technology is Gunther Hot Runner Systems (Buffalo Grove, IL). The company, which does a lot of work with high-cavitation packaging molds, has developed a nozzle with two fronts. The benefit, according to General Manager Joe Podge, is it permits removal of the nozzle from the hot-half or parting-line side of a mold for easy maintenance.

Gunther also has developed an actuation method for valve gates that increases the pitch density of nozzles. Without revealing details of the system, Podge says the company can install conventional nozzles within about 23.5 mm (0.9 in) of each other. The system not only maximizes the use of mold space, but contributes to process efficiency by eliminating the need to actuate two nozzles on one cylinder.

Materials

Parallel efforts to upgrade mold engineering are underway in metals technology. Suppliers are developing or refining grades to improve such features as mold durability, thermal properties and corrosion resistance. One such company is Böhler-Uddeholm North America (South Boston, VA), which recently commercialized several grades of mold steel and alloys that combine high hardness with properties tailored for diverse process needs.

The company’s newest product, Stavax Supreme, blends the toughness of H-13 steel (up to 50 HRC) with good corrosion resistance in a premium stainless grade that achieves uniform hardness in large cross sections. Patricia Miller, Senior Technical Manager, explains that the key property is corrosion resistance, which not only suits the steel for use in PVC molds, but minimizes the potential for corrosion from water lines, thus improving heat-transfer characteristics and cooling efficiency. Corrosion resistance coupled with the grade’s hardness also means reduced maintenance over the life of the mold. Stavax Supreme is said to provide an outstanding surface finish and high ductility, which suit it for use in complex molds.

Another grade that combines hardness with good heat-transfer properties is W360 Isobloc. Miller says the steel has a 52-57 HRC range and better thermal conductivity than H-13 grades. The material is claimed to be ideal for high-speed molding and for components like core pins.

Böhler-Uddeholm also is distributing an innovative copper alloy developed by ECOMold Products LLC (Milwaukee). Called ECOMold 95, the material has no beryllium, an ingredient that has raised health concerns among some moldmakers and end-users who believe that inhalation of minute particles causes respiratory ailments. For customers that want the conductivity of copper without beryllium, ECOMold 95 is an option. The material has a Rockwell hardness of 30, five times the thermal conductivity of steel and good tensile strength.

Summary

The ability to build packaging molds that produce high-quality parts at low cost is key to the competitiveness and profitability of North American moldmakers and processors. Most packaging doesn’t travel well, experts say, meaning local producers generally have an edge over offshore suppliers. But this advantage doesn’t guarantee profitability or market share. Utilizing fabrication and component innovations that speed tool building and assure fast cycles and repeatability in processing will give moldmakers the means to increase business and margins in this cost-sensitive market.

About The Author

Patrick A. Toensmeier has been writing about the plastics industry for 20 years. He can be reached at toensmeier@sbcglobal.net.

Related Content

Hot Runner Nozzles: Internally Heated Vs. Externally Heated

Why internally heated nozzles make more economic sense.

Read MoreSix Key Factors for Evaluating a Hot Runner System

Details matter when it comes to selecting and integrating a hot runner system. This guide makes that process easier by covering those details thoroughly.

Read MoreBreaking Down Hot Runner Maintenance

Improving a manifold’s maintenance plan requires specific skills and knowledge of its functioning areas.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Medical: The Right Rx for American Tool Builders

When technology, quality and speed step to the fore in the medical world, so does the North American mold and die industry with some innovative products and processes.

Read MoreIt’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreModular Mold Shell Design Increases Bottle Configuration’s Flexibility

In the beverage industry, bottle producers have been focusing on hotfill and heatset bottle applications such as juices, sports drinks, sauces, etc.

Read More