Seasoned Moldmakers and Advanced Technologies Give Del-Tool A Cutting-Edge Advantage

For Del-Tool Co. Inc., a seasoned crew using automation, five-axis CNC and shop management software is the edge needed for continued success.

Share

Read Next

What is your company’s chief competitive advantage?

Doug Brinker, president: Our company’s five-axis capabilities and use of automation. Also, we are a very custom shop, and most of our employees in each department are moldmakers, which is an advantage for the customer because our people know all the aspects of moldmaking. They know what they are doing and why they are doing it. For example, our EDM operator and our electrode designer/machinist are both moldmakers, and they understand shutoffs. They know how to adjust the burns they are making so when it’s a shutoff, it has steel there for properly shutting off. Those are the kinds of little things that are hard to teach if you haven’t actually built a mold. Their experienced eyes see problems before it is too late, often as early as the design stage, but also as they are working on the mold in the shop, which is so much better than finding out after the mold has been assembled and shipped. Some customers ask us what needs to be done in order to make a part more manufacturable. While we do not offer full product design, our team can assist with refining their part models to ensure good shut-offs and properly positioned draft angles and so on. This kind of contribution to a project is what ultimately affects our ability to perform the five-axis machining, not to mention other processes like carbon cutting, and using automation effectively.

How is your company using automation to advance your operations?

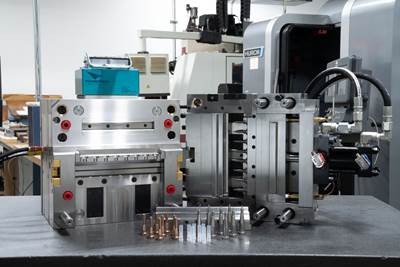

Brinker: We are using automation very successfully within our sinker EDM and CNC carbon cutting departments. We currently have four Mitsubishi sinker EDM machines, two of which are integrated with a System 3R WorkPartner robot, an 80-position electrode carousel and 10-position pallet storage system. We can run workpieces large and small in this cell and we operate it 24/7.

In our carbon cutting area, we have three high-speed machining centers: a Röders RFM 600, Röders RXP 500 (each with a 42,000-rpm spindle) and a Makino S56, which has a 20,000-rpm spindle. These three machines are set up with a centrally located System 3R WorkMaster robot that changes out electrodes, work pallets and cutting tools. This work cell also runs 24/7 and, combined with the EDM automated work cell, reduces our lead times and costs, which also benefits our customers.

Let’s talk five-axis machining. In what way has that been an advantage for your company?

Brinker: In addition to several high-speed, three-axis vertical and horizontal machining centers, Del-Tool has two DMG DMU 100P five-axis universal machining centers equipped with X, Y, Z footprints of 40 by 40 by 40 inches and 18,000 rpm spindles. Five-axis capability gives us the advantage to machine on five sides of a component in one setup, which saves time and increases accuracy. Our goal for every job, for example when performing such operations as machining tall coring, deep cavities and parting lines, is to ensure that we can design it to be machined as much as possible and reduce the need for EDM.

Scheduling is a critical part of the scenario as well. We use Shoptech-E2, a web-based enterprise resource planning (ERP) system that helps us manage quoting, scheduling, purchasing, shipping and invoicing. But it is the scheduling that’s key, not only to see where you are at with jobs but to be able to manage workflow more efficiently by knowing which jobs need to be done during working hours and which can be set up for running unattended. We've been focusing on scheduling and automation so that we can get more work done with fewer people. We are also cross training our team so that as workflow moves through different areas of the shop, our employees can help manage any bottlenecks.

In what other ways does Del-Tool ensure the satisfaction of its customers?

Brinker: I think it's the service after the sale, so to speak, and doing whatever we can to work on the molds as efficiently as possible. We have trucks here that are out on the roads every day to try to save days on different types of deliveries. Whether it's a repair or revision, or a new tool, all those days add up. If you're just shipping U.P.S. or common carrier, you lose at least a day on each end of that shipment for services on the outside, so we do what we can to save time and deliver the completed mold on schedule, ready for production.

We have one shift, but it starts at three or four in the morning and goes until five or six at night because some employees like to start early. I like having our employees’ hours staggered throughout the morning and into the evening. It’s like having two overlapping shifts, plus we run our machines unattended every night. It enables us to get more work completed faster this way.

How does your shop deal with the ups and downs of the automotive market?

Brinker: The automotive market is not a majority of our customer base, but when there is a slowdown in that particular industry, we will take on some custom machining projects and job shop type work to fill in the work schedules. Also, we can give our customers an advantage by reducing costs and/or lead times when we have less of a backlog of work. The flow of mold repair and revision work is generally pretty steady, so we are able to react to customers’ needs in this area a little more quickly than when operating at a higher, new-tooling capacity.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

Strong Design and State-of-the-Art Equipment Gives Omega Tool a Competitive Edge

Design expertise, supported by cutting-edge CNC, materials, software and inspection enables Omega Tool Inc. deliver notably robust molds.

Read MoreExperience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

Read MoreBuss Precision Mold Reaps Success from Building Complex and Reshored Molds

A shift in core competencies, including re-shored molds, gives Buss Precision Mold an edge on high-precision moldmaking and laser-focused customer service.

Read More