2014 Leadtime Leader Awards Honorable Mention: Aalbers Tool & Mold Inc

A rush of recent change for this moldmaker belies a long-term growth strategy that’s anything but aggressive. Key aspects of this cautious approach include strategic expansion, continuous improvement, extensive data tracking, and investments in workforce development and environmental sustainability.

When Gary Aalbers and Toni Hansen retire, they’ll leave behind more than just a company. Judging from the way Hansen talks, they view the shop that bears Aalbers’s name as something more akin to an institution, one with long-term responsibilities to its workforce, its customers, its community, the broader industry and even the environment. “Gary and I want this company to stay healthy and provide a gainful place of employment long after we are gone,” he says.

All indications are that Aalbers Tool and Mold Inc. is well on its way to meeting that goal. The plastic injection mold manufacturer’s on-time delivery rate is 98 percent, approximately 20 percent higher than 10 years ago. The expansion that brought the Canadian company’s Oldcastle, Ontario, facilities to a total of 100,000 square feet of manufacturing space is less than a year old, as are some of the most critical pieces of equipment on the shop floor. The case is the same for a new division focused on manufacturing of standardized mold components in-house, as well as an entirely new plant in Mexico. Moreover, the operation was at 85 percent of total capacity by the time this article began to take shape. Barring any unexpected developments, Aalbers Tool and Mold has likely continued to add work, and it may have already made good on plans to add to its 124-person staff as a result.

However, these recent developments could lead an outside observer to form the wrong impression. This is not a firm that’s prone to taking gambles or making aggressive moves in the marketplace—at least, not without a great deal of planning, says Hansen, company president. Although the pace of recent expansion is unusual, he says the developments outlined here have been a long time coming. They’re simply the latest successes attributable to a philosophy of slow, steady growth that has driven the company for more than three decades.

This forward-thinking philosophy starts with a relatively basic premise: Don’t spend beyond your means. However, there’s far more to it than that. Strategic expansion of services helps bring in new business while simultaneously building on core competencies. Standardization efforts streamline operations in their own right while also fostering a culture of continuous improvement. Extensive data tracking aids decision-making by providing deeper intelligence into the shop’s own operations. Finally, investments in workforce development and improving environmental sustainability reveal a company that truly values long-term success over short-term gain.

Hansen says he and Aalbers view this long-term approach as critical to building a business that will remain a fixture in its industry and community long after they retire. In the meantime, the factors mentioned here make the company more than worthy of the “Honorable Mention” title in this year’s Leadtime Leader Program.

Sustainable Growth

After all, these pillars of Aalbers Tool and Mold’s big-picture strategy have taken it a long way since 1982. That’s when Aalbers, founder and CEO, rented space in the corner of another shop to accommodate just a few employees and machines. The company weathered plenty of lean periods during the next three decades as it found its niche in interior and exterior automotive trim molds, which now account for about 80 percent of business (tooling for recreational vehicles and consumer products rounds out the other 20 percent). Hansen credits the shop’s focus on the long term for its ability to maintain competitive pricing, quality standards and profitability without laying off a substantial portion of the staff.

He explains that this focus provided the wherewithal to add capacity only when needed—and only when the company could do so without taking on too much debt. That said, competitiveness has always depended on investing in the latest technology. Indeed, he credits advances in software, high-speed and five-axis machining, automation equipment, and more as critical to reducing average lead times from 16-20 weeks a decade ago to 8-14 weeks today. Asked how the company has managed these seemingly contradictory goals, Hansen says it all comes down to carefully prioritizing expenditures.

Consider the recent purchase of two OPS-Ingersoll Gantry Eagle 1200 EDMs from MC Machinery Systems that have dramatically reduced burn time, electrode wear and the need for polishing. In isolation, however, these benefits weren’t enough to justify the investment, Hansen says. After all, different machinery could likely provide similar gains in other areas of the shop. Nonetheless, EDM is always a priority, because this operation usually can’t be postponed or reshuffled in the process without delaying the build (as opposed to, say, gundrilling). Similarly, the purchase wasn’t motivated solely by the fact that the four EDMs replaced by the new machines were outdated. A greater concern was that those older machines were no longer performing. (In contrast, there are no immediate plans to replace a 15-year-old boring mill that still keeps up with the work assigned to it.) In short, the company has thrived by recognizing—and prioritizing—investments with the most potential to impact not just a single operation, but overall lead time, Hansen says.

Whether investments involve equipment purchases or broader endeavors, their viability depends one metric above all others: profit margin. As long as the goal is sustainable growth—as opposed to just growth—profit margin provides a far better indicator of success than raw sales, revenue or other commonly cited figures, Hansen says.

Strategic Expansion

Using profit margin as a litmus test for decisions has helped the shop not only grow its core offering sustainably, but also expand into new services as painlessly as possible, Hansen says. Such services tend to both jibe with core competencies and attract enough new business to support themselves. For instance, the company’s 15-year-old dedicated gundrilling operation acts as a contract shop in its own right while eliminating the need to outsource an operation common to most tool builds.

Other examples are more recent. In 2009, an important customer prodded the company to produce tools that enable in-mold laminating, a technique used to adhere cosmetic fabric to interior trim parts during the molding process. Despite a significant learning curve, these tools provided an opportunity to eliminate various secondary processing steps for the customer. Moreover, adapting to the challenges of manufacturing a new type of injection mold was far preferable to taking on anything that might require significant capital expenditures, particularly in the midst of a recession. And although Hansen estimates cloth-inlay molds account for only about 5 percent of the interior trim market, this specialty has already opened the door to plenty of new work. “If there’s a program that involves cloth-inlay tooling, we’ll likely be on the quote list,” he says.

The company’s latest foray is a new plant in Queretaro, Mexico, that will provide local service and support for the increasing volume of tools shipped to molding facilities in that area. Consisting of a rented facility and just a few machines, the new operation should generate more than enough return to sustain itself, Hansen says. That’s because it will help capitalize on demand for a single-source supplier, just as the company did with cloth-inlay tooling, without the expense and delay associated with travel. In fact, plans are already in the works to add end-of-arm tooling services and possibly even a sampling press.

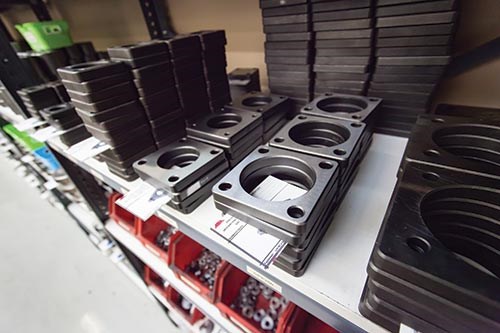

That’s not the only new endeavor expected to provide an additional revenue stream. As part of its recent Ontario facility expansion, the company dedicated space to a new business division focused on manufacturing standardized mold components, which the company will likely bring to market. However, Hansen emphasizes that the components division is not so much a work in progress as the culmination of years of efforts to streamline the manufacturing process—efforts that have already driven a transition to what can only be called a culture of continuous improvement.

High Standards for Improvement

Although phrases like that are common in manufacturing circles, Aalbers Tool and Mold rarely goes more than a few months without improving some aspect of its production process, Hansen says. Moreover, this change tends to be driven from the bottom up. What he refers to as “some of our greatest productivity gains” trace their origins to the same place as the company’s growing collection of patent-pending component designs: monthly meetings where employees discuss recent tool builds and suggest improvements to the overall process.

Standardizing wear plates was an early instance of a shopfloor suggestion that led to significant productivity gains. Batch production of standard plate sizes and configurations has reduced not only the time required to design and manufacture these previously customized components, but also the potential for error, Hansen says. Additionally, personnel can simply pull a plate from stock rather than waiting for one to be machined, whether for a new build or to ship to a customer.

All in all, the company has created more than enough components to dedicate an entire division to manufacturing, storing, and possibly even marketing its designs, Hansen says, noting that the pace of new ideas from the shop floor shows no sign of slowing down. “When people care, they do better work and produce better tools,” he explains. “Seeing their suggestions successfully implemented helps encourage even more ideas.” He adds that this model is particularly important for long-term success because engaged employees set a good example for apprentices and new hires.

Data-Driven Decision Making

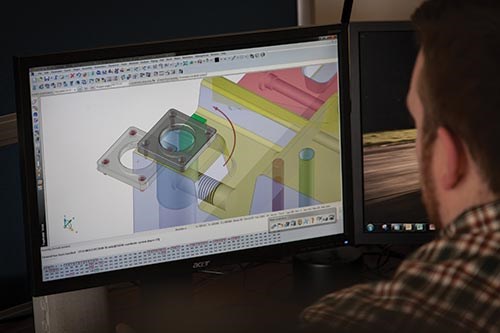

Recognizing that the people closest to a process are best equipped to improve it has been critical to streamlining and standardizing operations—and by extension, improving lead times, Hansen says. Just as important, however, is the fact that process changes are guided and measured not just by inherently subjective human beings, but software that tracks every step in a tool build.

Informally referred to as “overview,” this home-grown system developed gradually over the course of about 15 years. As a mold progresses through the shop, employees in each department check off each step in the process and enter the amount of time it required. The system then compares that data to how long each step should take. This determination is informed heavily by previous data, but project managers also tweak the numbers to account for process improvements as well as the intricacies of a particular job, Hansen explains. Based on this information and the overall delivery date for the completed mold, the software automatically determines an individual deadline for every department and issues an alert in the event of a delay.

Beyond just keeping builds on track, the system helps identify recurring problem areas that might make good targets for improvement. Meanwhile, data tracking helps evaluate the true effects of any changes. The software also plays an important role in forecasting how changing existing workflow or adding new jobs might affect the operation—and profit margins. “We understand our capacity; we understand our capabilities; we understand how long something will take; and we quote all our jobs using this knowledge,” Hansen says.

Aalbers Tool and Mold isn’t stopping there. The company is working to migrate data from overview to E2, an ERP system from Shoptech Software (Glastonbury, Connecticut). Once fully implemented, E2 will cover not only job tracking, but also such business functions as accounting, shipping, inventory management and more. Hansen expects these additional synergies to improve future decision-making by providing deeper insight into the intricacies of the company’s own operations, just as overview did in the past.

However, he emphasizes that even the deepest insight doesn’t always lead to the best decisions. Whether strategizing about a single task or the direction of the entire company, much depends on the judgment of individuals. Given that this isn’t likely to ever change, investing in people is far and away the most important factor in ensuring success long after he and Aalbers leave, Hansen says.

A Bottom-Up Approach

That starts with providing a good place to work, he says. As evidence of the company’s success, he cites an employee turnover ratio of 7 percent and an average length of employment of 11.5 years. In part, that’s due to a willingness to make simple gestures—a barbecue, a long weekend—that show employees that they’re appreciated. It’s also important to keep employees engaged through such activities as the aforementioned improvement meetings.

Beyond that, a strategy of promoting from within avoids stagnation and discontent by ensuring plenty of opportunities to advance, Hansen says. In the event that no one has the needed skillset for a position, the company often encourages—and pays for—an existing employee to pursue any needed training rather than hiring from outside. “There are only two people in management today who didn’t start out on the floor,” he notes.

Advancement opportunities can be particularly encouraging for the shop’s apprentices, which constitute almost half the people on the shop floor in any given year, Hansen says. Most come to Aalbers Tool and Mold through the Ontario Youth Apprenticeship Program (OYAP), which enables them to complete their secondary (high school) education while gaining real trade experience. Starting in grade 11 or 12, the students spend a few half-days a week learning the basics of the trade at the shop. After graduation, the company accepts them as official apprentices. For the next three years, they spend most of their time at the shop, although they supplement their toolmaking education with more generic courses at a local community college.

Apprentices emerge from the program with years of paid, real-world experience, a journeyperson certificate, and, typically, a job—all for a modest cost (less than $2,000) that’s often alleviated by government tuition subsidies. Of course, for a forward-thinking company like Aalbers Tool and Mold, the time and cost investment pales against the benefits of ensuring a viable future workforce, Hansen says.

A Responsibility to Posterity

The company’s long-term focus is also evidenced by its willingness to invest in environmental sustainability. Examples include replacing sodium lighting with high-efficiency fluorescents and petroleum-based coolant with a biodegradable formulation. Last year, the company planted more than 50 trees on its grounds, and another 50 are slated for planting this year. The most significant recent development is the installation of rooftop solar arrays that, when completed, will make Aalbers Tool and Mold the fourth-largest producer of solar power in the city.

Some of these investments provide an immediate, tangible benefit. For instance, recycling excess steel and carbide provides a modest revenue stream, Hansen says. Mostly, however, the company is motivated by a sense of responsibility to posterity. After all, he isn’t just president of Aalbers Tool and Mold—he also operates a 14-acre farm and a small vineyard. Aalbers, for his part, once donated a significant parcel of land to local conservation efforts. They’re also both parents. Suffice to say the company’s top leadership views environmental sustainability as critical to their legacy and the company’s future. “We’re not tree-huggers by any means, but being environmentally conscious is not just an option for us,” Hansen says. “We have a responsibility here.”

Related Content

MMT CHATS: Navigating Challenges and Innovations in Large-Scale Mold Manufacturing

MSI Mold Builders shares how to overcome large-scale mold-building challenges, sustainability efforts and future technological advancements.

Read MoreMMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVIDEO: Hot Runners and Sustainability

Oerlikon HRSflow North America Sales Director Robert Harvey breaks down hot runner technology that addresses sustainability opportunities and challenges.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreRead Next

2013 Leadtime Leader Award Winners

Through this year’s Awards—presented by MMT and Progressive Components—we honor two outstanding mold manufacturers who demonstrate excellence in overall innovation, efficiency, quality and commitment.

Read MoreCommon Keys to Success

This year’s Lead Time Leader award winners have more in common than meets the eye, including heavy investments in workforce development and a bottom-up, employee-driven approach to continuous improvement.

Read MoreCritical Equipment at Aalbers Tool & Mold

EDMs that have slashed burn time by a third and two five-axis machining centers are among the latest equipment implemented at the winner of this year’s Lead Time Leader—Honorable Mention award.

Read More