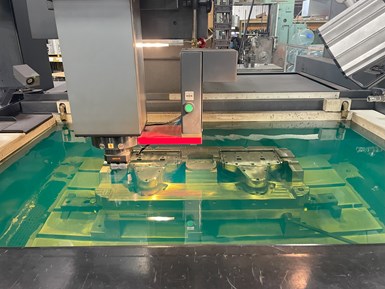

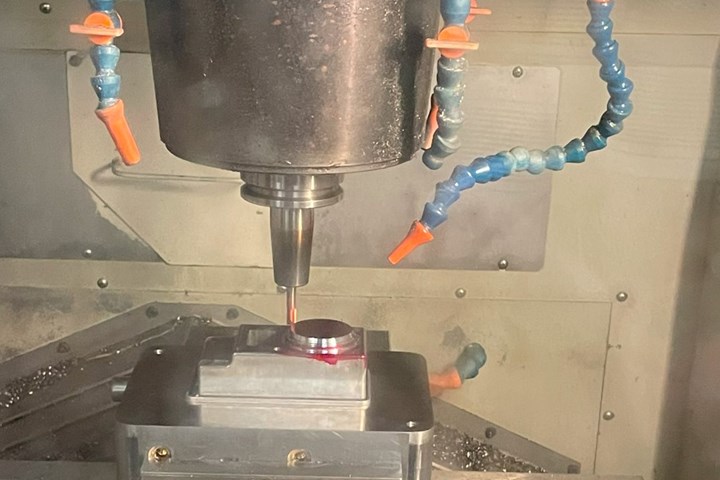

Mayer Tool & Engineering (MTE) specializes in designing and building quality injection molds for the plastics industry. From concept to completion, they handle everything from initial mold design and engineering to the final product. Photos Credit, all images: Mayer Tool & Engineering Inc.

What is Mayer Tool & Engineering, and what is your chief competitive advantage?

Patrick Roussey II, president, Mayer Tool & Engineering: Mayer Tool & Engineering (MTE) is a family-owned business founded in 1982 that sees customer success as the top priority. Our chief competitive advantage is the team’s ability to adapt, problem solve, brainstorm and work together to support our customers’ needs.

MTE relies on collaboration among its 30 employees working in office administration, project management and sales, engineering, molding, shipping, CNC/EDM, tooling and mold building to get the job done.

We are located in a 14,000-square-foot facility in Sturgis, Michigan. We specialize in custom injection mold building for the plastics industry, including product development from initial concept to mold sampling. For 40 years of business, MTE has provided exceptional tooling across multiple industries with the same end goal: customer success. Our company’s achievements can be credited to the collaboration of our 30 employees working in office administration, project management and sales, engineering, molding, shipping, CNC/EDM, tooling and mold building.

MTE provides exceptional tooling across multiple industries with the customer's success always in mind.

One of MTE’s biggest strengths is our diverse customer base, which continues to grow. Industries served include automotive, appliance, lawn and garden, hunting and fishing, RV, marine, packaging and consumer goods. Collaborating with these various markets enables us to adapt and proactively seek new manufacturing techniques that exceed our customers’ expectations. We have a supplier/partner in Shenzhen, China, to serve the offshore tooling needs of the industry.

In addition to mold building, we provide expert processing with our five in-house molding machines ranging from 77 to 500 tons. On-site molding capability provides customers with all of the necessary information from process reports, short shot studies, videos from the trial and sample parts. Nearly all molds are sampled at MTE before shipping.

MTE offers expert processing with five in-house molding machines ranging from 77 to 500 tons.

What is the ideal customer relationship?

Roussey: We value great working relationships with all of our customers. Whether with an OEM supplier or a molding facility, a high level of communication is key to best supporting our customers from start to finish of every project.

What is the most significant change in your general approach to business?

Roussey: The biggest push of late is finding and bringing in new talent ready to be coached, so Mayer Tool has invested in the training and apprenticeship program. It’s about finding talent and matching the skillset with the right mentors to facilitate that training through time spent on the bench and during machine operation.

Another thing to note is the push for less traditional manufacturing techniques. This may not have been the case in years past, but lately, MTE has been extremely open to new methods that may be more suitable than standard processes. For example, MTE has been exploring additive manufacturing (AM), conformal cooling and 3D printing improvements.

We are committed to evolving as a full-service mold builder by constantly improving our low-volume production and sampling capabilities, which has led to an enhanced and streamlined experience for customers who rely on our cost-effective tooling and molding to launch new products.

What is the most significant change in your use of technology?

MTE is committed to growing as a full-service mold builder, continuing to manufacture cost-effective tooling and molding to launch new products.

Roussey: Technology continues to evolve in the industry — from AM to improved automation practices. For MTE, an automated end of arm tooling (EOAT) robot has been the latest advancement added to the shop. The robot is linked to a new 500-ton Tederic injection mold machine that aids large part sampling. This upgrade in our molding department allows us to test and prove out any EOAT we build for our end customer’s high-volume production needs.

A newer update in office technology for us as a small business has been implementing a VPN login system for remote work. While we currently have two full-time, off-site project managers that use this daily, this option also allows additional MTE employees to be available to our customers while traveling or outside the office.

How do you expect your business to evolve regarding technology and business strategies in 3-5 years?

Roussey: Our key business strategy is to use the correct tools when our customers need us. We strive to do whatever is required to continue growing our MTE capabilities to contribute to our customers’ success.

For example, our recent focus is on software for CNC programming, job tracking and employee training. These areas provide the foundation for each mold build and the company. We will continue to invest in equipment and technology to assist our employees because numerous innovative and time-saving devices are on the market.

We are also committed to evolving as a full-service mold builder by constantly improving our low-volume production and sampling capabilities. This has led to an enhanced and streamlined experience for customers who rely on our cost-effective tooling and molding to launch new products. Typically, these customers come to us from niche markets and very quickly see the benefits of our full-service business model.

In addition to expanding capabilities, we are looking at new technologies that enable us to supply components quicker and as cost-effective as possible. Technology is changing quickly in this trade and staying at the forefront of technology is very important to us.

Does your company have a difficult time finding and attracting new employees? Please tell us how you are addressing the skills gap.

Roussey: There is no denying a shortage of qualified employees in the industry, particularly in the last 10 years. MTE is fortunate enough to presently employ very skilled, well-trained moldmakers. However, there will be a gap between this talent and the next generation of moldmakers. We are bridging that gap by providing apprenticeships and working closely with local high school (see “Reeling Them in Early: Exposing HS Freshmen to the Trades” sidebar) and university programs.

We see positive results by connecting the tried-and-true techniques of Mayer’s experienced team with those who come on board with an innovative perspective in manufacturing skills. The biggest point we try to make with those interested in moldmaking is that it is not just a job, but a career.

Besides investing in state-of-the-art equipment to assist with productivity, we believe fostering a healthy, family-focused, positive work environment helps pull in and retain the necessary labor force.

Describe the most interesting/notable mold project your company was awarded.

Roussey: This question is easy. The most meaningful project we’ve participated in was PPE tooling during the pandemic. The entire MTE team and our customers came together to build tooling to help protect the medical professionals, first responders and pharmacy staff fighting the virus. I hope and pray we never have to build tooling for something like this again, but it was great to see so many people working together for one cause.

During these particular tool builds, the focus was on speed and getting these components to the heroes on the front lines as quickly as possible. With everything they went through, it was great that the manufacturing community could help support them in this way. This is what being an American is all about. It’s coming together in a time of need and supporting each other through good times and bad. I am proud that MTE could be part of the PPE supply chain at that crucial time in our history.

Related Content

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreRead Next

Specialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreNext-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read More