Zero Tolerance designed and built this eight-cavity production tool and then took on molding the parts in-house. The shop used its Markforged 3D printer and design skills to 3D print a manual-loading claw to decrease cycle times and increase efficiency in the molding department. Photos Credit, all images (including landscape): Zero Tolerance

Who is Zero Tolerance LLC?

Steve Michon, President, Zero Tolerance LLC: Zero Tolerance LLC is a growing plastic injection mold machine shop in Clinton Township, Michigan. We have invested in the highest performance machinery and tooling along with staff, and are always willing to go the extra mile to ensure the best quality of customer service. Our team succeeds in moldmaking and production with a willingness to improve and learn new things. We strive to produce outstanding work by keeping up to date with the latest software, machinery and tooling. The most common-sized molds we build are medium-small in part size.

What’s in the name?

Michon: It’s two-fold: (1) The name defines the type of work we do and (2) it defines my wife’s tolerance for me.

Steve and Jamie Michon, owners of Zero Tolerance LLC, and loving parents of Evan, Noah, Wyatt and Eli Michon.

How did you get started?

Michon: Long story short, I’ve worked in the trade for about 15 years in Michigan. My wife and I then moved to Kansas and started a shop there. By doing that, I learned a lot about how the shop worked. Being an employee, you don’t really see what it takes. We saved for three years and put everything we could into the company. For help, I started with friends working as independent contractors for the services I needed. Otherwise, I was doing everything myself. Then our growing family needed support, so in 2011, we moved back to Michigan to continue the company there.

The Zero Tolerance 9,500-square-foot facility in Clinton Township, Michigan.

Fast forward to 2015 and I hired my first full-time employee — a young high school student who was a mechanical genius. He worked for me for three years. This year we are celebrating 10 years in business. We moved a year ago to a new 9,500-square-foot facility in Clinton Township. We currently have 14 employees and are working towards incorporating an apprenticeship program shortly.

Can you name one thing that motivates you at work?

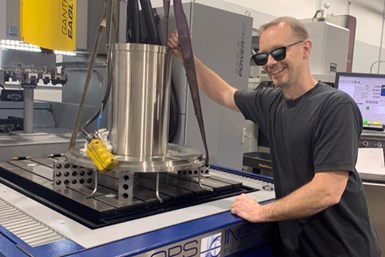

Co-owner Steve Michon putting in a large part to be EDM’d in an Eagle Sinker, using Sunspot Tooling extension chucks and holders to burn in areas that are difficult to reach.

Michon: Knowing that I’m using my skillset to serve someone. When I come up with an idea, design it, build it and then solve a problem with it.

What is the company’s sweet spot?

Michon: We thrive with the more complex tools with many actions — slides, lifters and complex geometry. We tackle jobs that are not super common. We reach for higher-end tooling projects across oil and gas, medical and consumer goods. We do not do much automotive work.

What do you consider your competitive advantage?

Michon: Solving customers’ problems quickly and on the fly. We’re known for our high quality in designing and building precise injection molds that last. Because we’re a small team of 14, we can make changes rapidly without a lot of bureaucracy. When something needs to be fixed, changed or modified, the customer is after speed, and we can offer that. We’re agile. We also credit Cimatron for our ability to make changes on the fly.

What is Zero Tolerance’s culture?

Michon: Embracing change. We have a nice blend of old-school-type mold builders and new-generation moldmakers, which helps us not fear change and embrace new technology, which is a big thing in my book. You must learn new technology even though initially it may seem harder. Processes become more efficient if you stick with the technology and take advantage of all it offers.

Run down your stated core values — innovation, transparency, accessibility and

Ethan Fleury, the shopfloor organizer and JobBOSS guru, keeps the shopfloor flow accurate and steady.

relationship.

Michon: Innovation is something I’ve craved since I was young. I always liked making something that didn’t exist. I grew up in the trade thinking about a square block of steel. How am I going to hold it? How am I going to machine it? Innovation is all about thinking outside the box. Can we do it differently, more effectively, etc.? Innovation is trying to see a project in a way that makes more sense.

Transparency ranks right up there with integrity. We’re not perfect. We’re going to try our best, but when we run into trouble, we’re straightforward about it with the customer — this is what happened and here’s our plan to fix it. We are proactive.

Accessibility is my struggle as an owner. I want to be able to help everybody that comes to me, but sometimes, I’m not accessible to everyone. So I’m learning to hand off a task to whomever I deem necessary to ensure the customer gets what they need when they need it. But, again, it’s about being there.

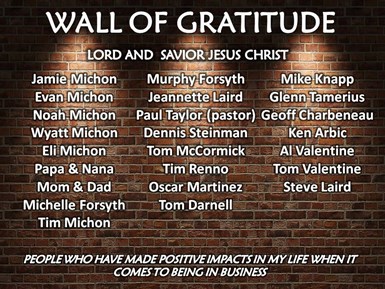

Relationship means what we do is personal. We have a lot of pride in our work. Hence our Wall of Gratitude.

What is the Wall of Gratitude?

The Wall of Gratitude is at the heart of what Zero Tolerance is all about.

Michon: I’ll say this: If you see a turtle on a fence post, you can rest assured he did not get there on his own. It is with this in mind that I created the Wall of Gratitude. I wanted to express my gratitude to the people who helped me over the years to get me where I am today.

I must mention that God is at the top of the wall. My faith in God is of the utmost importance. Someone designed all of this, and it surely wasn’t me. To have a small part of creation is my gift back. I put this wall together eight years ago, and it will continue to get bigger because the more the company grows, the more people we have to thank.

What do you look for in an employee?

Michon: Someone who is not afraid to make mistakes.

What is your number one challenge with the business so far?

Michon: Delegating more of my tasks to others. I don’t want to lose touch. So my challenge is giving people a task, believing in them and stepping away.

Talk about the technology. You mention investing in the highest performance machinery and tooling, so please explain.

Michon: The first machine I bought was really old and broken down. I purchased it with my tax return that year and spent 3.5 months rebuilding it, which taught me how all the mechanical components work. After that, I got it running and it ran for five years. Then I sold it for double what I bought it for! I have always been after accuracy in machine tool technology versus speed. If I could be more accurate, it would save me time, even if it wasn’t fast. The goal is to cut once and be done cutting.

Mike Tietschert is programming and setting up the Mitsubishi EDM sinker for the next job.

So, on the metal cutting side, key technology includes our wire and sinker EDM machines, with which we can do much more with less effort, reduced costs and more speed. EDM technology is powerful. When we moved into our new building, we purchased the Ingersoll Eagle EDM, and the technology behind this machine is impressive. We can burn faster and use fewer electrodes per burn.

Also, adding a five-axis Makino to our shop is one of our best decisions in the last three years. It changed the way we think and process mold details. The amount of work that can be done in one setup is truly a game-changer. This machine also allows us not to EDM many areas we would have typically needed to burn. We plan to add another larger five-axis very soon.

Steve is checking out the latest print started 20 hours ago on the shop’s Markforged desktop printer. An essential technology for Zero Tolerance is its Markforged X7 printer acquired with the help of Automation Alley.

On the plastics side of the business, we have our two injection molding presses. I believe having these machines in-house makes us a better mold builder. As a result, we can solve issues — via scientific molding practices — before they cause problems, resulting in better customer service and a better end product.

We also joined Automation Alley, through which we received a Markforged printer. This technology has opened our eyes to the endless possibilities for additive manufacturing (AM) in our industry today.

3D printing has changed the manufacturing mindset. It’s a different thought process. We work with Jason Murphy of Next Chapter Manufacturing and regularly discuss the possibilities and challenges of 3D printing. We have MarkForged printers that we’ve used to solve many in-house problems. For example, we’ve printed CMM fixtures, pad printing fixtures and end-of-arm tooling that helped us go from an eight-day molding process to four days. We call it the claw, and it loads eight inserts at a time. We’ve also made curved slides that needed a conformal cooling circuit. We print parts for ourselves and our customers. We can’t function without it.

Lead inspector Michelle Forsyth checks molded parts and packaging.

Talk a little bit about your journey with the molding side.

Michon: For the first five years we were in business, I tried to get involved with molding, but I couldn’t dedicate the time. Then, a customer presented a challenge that pushed us to invest in a press to take on some production molding. We bought a brand-new press, received excellent training, had the thing up and running and haven’t looked back. We ended up getting a second press. We believe our expertise in moldmaking assists in the molding process to guarantee high-quality parts to our customers. We have two in-house presses for mold tryouts: short and volume production runs. Our press specifications are:

- One hundred and thirty eight-tons.

- Six-ounce shot size.

- Minimum mold height (thickness): 9.9 inches.

- Maximum mold height (thickness): 21.7 inches.

- Minimum mold length (top of mold): 10.4 inches.

- Maximum mold length (top of mold): 25.6 inches.

- Minimum mold width: 9.4 inches.

- Maximum mold width: 18.1 inches.

What are a couple of recent process improvements?

Michon: We are implementing JobBOSS software to improve the workflow on the floor and maintain consistency in our processes. We’re building a video training series to help us transfer knowledge to others.

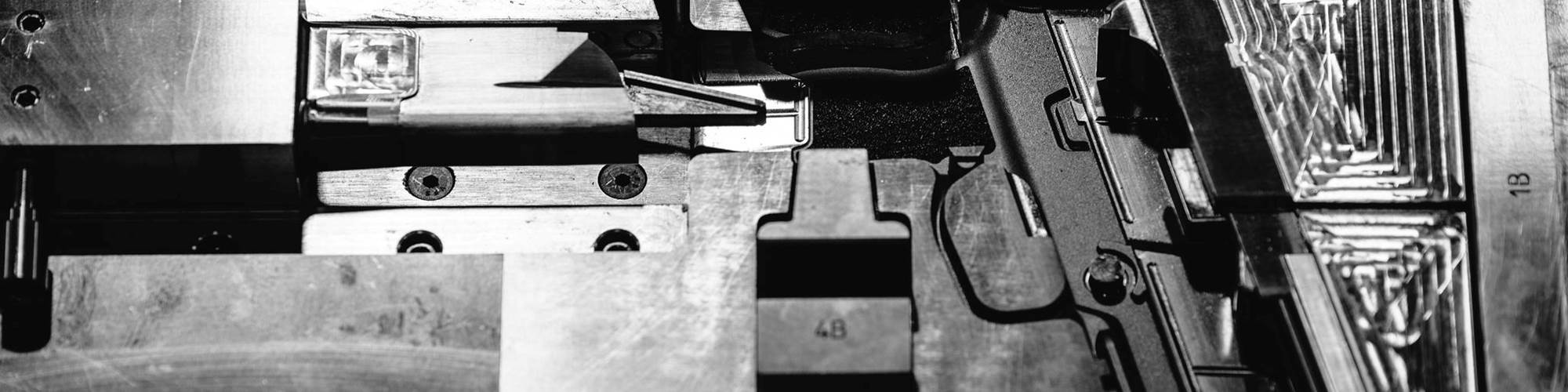

Two-cavity production mold for a gun magazine that required 3D-printed slides enabled Zero Tolerance to have conformal cooling where needed.

Share a challenging mold project that put the team to the test.

Michon: It has to be the 30-round AR15 gun magazine we designed and built (a curved magazine with hydraulic cylinders). It was a two-cavity mold with three slides coming together and an internal slide that made an undercut inside the gun frame. The overall function of this mold was cool to watch. One was a grip; the other was the magazine. The gun had a lot of action — multiple slides and then a slide-in-the-slide combination to make features and undercuts in the plastic.

A curved, 30-round AR-15 magazine for a two-cavity mold, finish machining on an F5 Makino.

Then the challenge was getting it to fill. We had to have a hot valve-gated hot tip on one point of the part that was very difficult to get to. Even the manifold manufacturers did not want to do it because the shape would void their warranty. We identified a manifold partner and made it work. We used a lot of software to simulate a hot manifold and where it should go. The magazine had a lot of unforeseen shrink in the part, so we had to go back and forth. Moldflow helped us solve their warpage problem.

What technology or process was vital to this project’s success?

Michon: Everybody talks about efficiency with getting a program to run perfectly. However, I believe it’s not about going faster; it’s about maintaining accuracy, which makes setups priceless. A key technology is our use of automation on our five-axis machine because of how the machine was designed to work around the fixture.

A two-cavity gun grip tool with hot drops and three slides per cavity.

You are active on social media. Can you share your strategy?

Michon: Five years ago, I read a book about exposing who you are and not what you do. Fortunately, my niece, Murphy, working part-time, was into social media and helped us build a campaign. She is the wizard behind the curtain. Our plan is focused on pictures and videos. But these are not random; it’s typically something that I think is interesting or that I’m proud of. It’s also a matter of being interactive. You have to engage. The key to all of it is feedback. We get a lot of questions, so we are sure to answer and help them solve a problem.

How do you measure success?

Michon: The company’s growth, number of repeat customers and better profitability. On top of those metrics is more family time. So, if I set it up correctly, manage it right and put the right people in place and let them do their jobs, then that’s a success.

Let us in on some future plans.

Michon: Our focus is on expanding the molding area and investing in more automation in the tool shop, making it easier for us to do what we do and keep speed and accuracy at the forefront. We wouldn’t have had the molding if we didn’t have a good mold shop. In addition, we see more training and apprenticeships that bring the younger generation into our business.

Related Content

Speed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Local Moldmaking Expertise with Global Competitiveness Takes on Tooling Innovation and Training

From quick-change solutions and world mold systems to offshore tooling consulting and project management and apprentice training, this Pennsylvania mold builder continues to advance.

Read MoreCurrent Technology and Trends in a Micro Molding Tooling Center

Contract manufacturer of medical micro components and finished devices discusses current trends and challenges with micro molds—micro milling, cutting tools, mold coatings, CAD/CAM, micro welding, mold design, micro molding, validation, automated assembly and training.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read More

.jpg;maxWidth=970;quality=90)