Eden Tool’s latest investment is a molding press, to fully validate molds prior to installation. This is morphing into a new profit center, Eden Manufacturing, to offer full service to medical manufacturers. All photo credit: Eden Tool and Eden Manufacturing by Creative Technology Corp.

Four years ago, 14-year-old Jake Eden finally fessed up to his father that he had no interest in taking over the family's mold-building business. His reason was three-fold, and it set Eden Tool in an entirely new direction, but with a continued focus on performance:

- He wants people to respect him and believe that he earned the right to the business.

- He has no interest in working with his hands. He wants to create and design.

- He wants to build something of his own. He wants his own medical line.

The question became, "Dad, how can I take your business and grow it into something I can be proud of, and that's mine?" His father's answer was medical device manufacturing.

“Details make the difference” is a way of life at Eden Manufacturing.

Molding was something Mike Eden, owner of Eden Tool Company (New Freedom, Pennsylvania), was never around and something his customers were continually asking for — technology and services on top of their extreme mold-building capabilities. It was then that the concept of Eden Manufacturing, a manufacturer of engineered medical components, was born, and a plan was put in place to make it happen.

Today, Jake is attending Penn State's main campus with a major focus on biomedical engineering and mechanical engineering. He wants his own medical line, and is currently dreaming about prosthetic concepts alongside the vice president of Eden Manufacturing, Dave Tomic. Jake is a next-generation manufacturer in the making.

But let’s back up because this team didn't get here overnight, which makes for quite the story.

Eden Tool was founded on a penchant for high performance. These cars are a big part of life.

Hot Rods and Molds?

“Everything we’ve done up until now has led us to Eden Manufacturing,” Mike Eden says. After spending only a day-and-a-half at the shop, I learned that at the core of Eden's story lies a focus on the details and something they refer to as predictable manufacturing, which all comes from a love of hot rods.

Jake has been tinkering with hot rods for as long as he can remember, alongside his father, who took his love for hot rods and the required attention to details and applied both to the moldmaking process at Eden Tool.

MoldMaking Technology Editorial Director Christina Fuges with Mike Eden, discussing performance, even in classic Collector Cars.

"Hot rods are a part of me. My father was always into cars, and there was always someone in the garage where I hung out. It was there that I fell in love with cars and learned the importance of attention to detail and its impact on taking a car to the next level. So, when I started my own tool shop, my focus was on cleanliness, attention to detail and machine performance, which tie directly to the hot rod industry," Eden says.

One of Jake Eden’s custom designed hot rod parts, a fully machined air cleaner cover. Jake was 15 years old at the time.

Hence, the flames in the Eden Tool logo as well as the checkerboard floor across the shop. But it's not just about performance; it's about predictable performance.

Tooling Philosophy and Technology Relationships

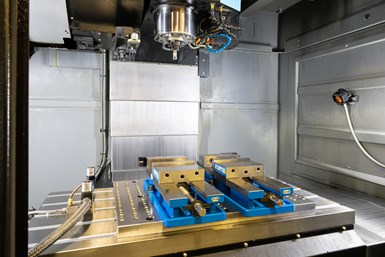

Eden Tool, a 12-person medical mold builder, known for its high-end EDM, grinding and hard milling capabilities, is about predictable manufacturing, and hard milling is a powerful tool in the toolbox of predictable manufacturing. “We don't just mill hard materials. Hard milling is part of our predictable manufacturing process,” Mike says.

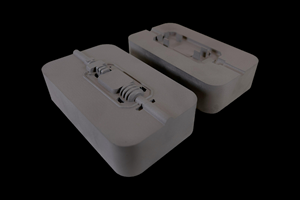

This mold for a respirator part is all about complex details with critical feather-edged mating surfaces. Inserts were hard milled to finish, with no fitting required.

He uses the word extreme when it comes to his equipment, especially for hard milling. He explains that their hard-milling process yields consistency from cavity to cavity — identical cavities — which is a very big advantage in the medical industry because of the required CPKs and validation.

So, where did this predictable philosophy come from? Well, it stems from a strong partnership between Eden and Tomic. Tomic graduated in 1995 out of high school and completed two formal trade apprenticeships — tool and die, as well as moldmaking. He excelled in CNC and hard milling in particular, but for him, it was more than a machining process; it was a manufacturing process. He wanted to use this process to impact and revolutionize how he built tooling. It was the whole system.

“We changed our tool designs. We designed for hard milling, then we leveraged the hard milling for those designs. It was a back and forth. You had to change the philosophy. Designers had to realize what hard milling could do to benefit from it,” Tomic says. For him, this meant development in CAD/CAM and better die/mold tool paths. He took on the challenge of improving programming techniques for hard milling.

Mike Eden explains these high-cavitation refurb stack mold inserts, hard milled mating surfaces with no fitting. Performance has demonstrated three times the life for these inserts as compared with traditionally EDM-produced inserts.

“When I started developing hard milling many years ago, it was centered around predictable manufacturing. How can we put a block in and how can we program it, macro-based with certain defined processes and come out with a very tight expected result — using lasers, macros, automation, specific CAM software and algorithms?” Tomic says.

He wanted accuracy first, predictability next, which equals speed. It's the order that he's always worked in. “If you can't deal with it accurately, there's no point in being fast. You just make fast garbage,” Tomic says.

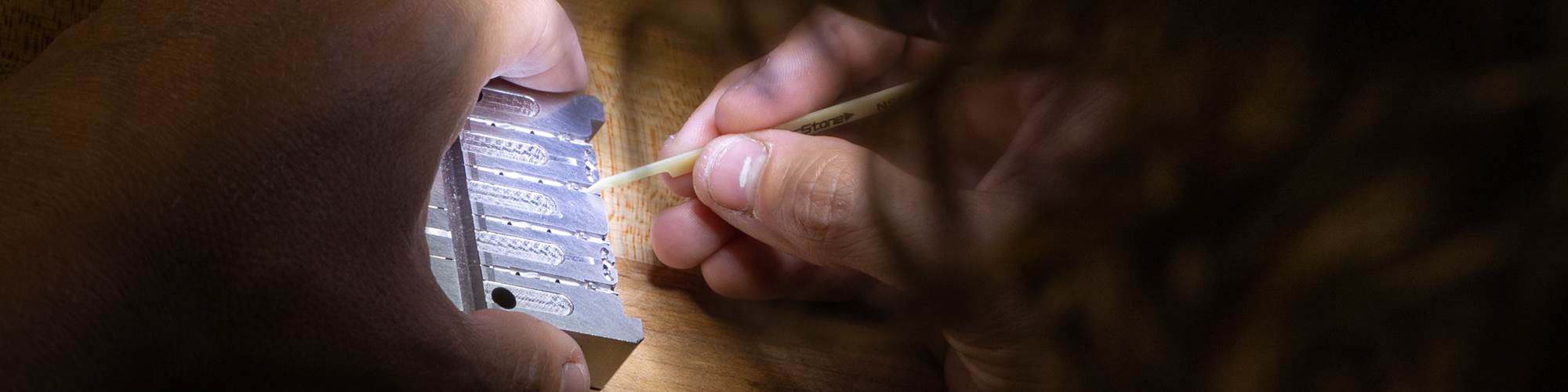

Polishing critical micro-mold details under a microscope.

All of this takes strong attention to detail, and it is that which Eden and Tomic have most in common. Initially, the two connected over programming assistance the Eden Tool team needed with its hard milling. Dave's attention to detail, software training, templates, tool macro library and consignment package were the answer.

Years later, as Eden decided it was time to grow and focus on the business more, he realized that he needed more qualified people. So in early 2019, as he evaluated metrology and hard milling equipment, he hired Tomic as a consultant because of his attention to detail and technology relationships. By that, I mean his relationships with the people who represent the technology. “The answer is not the equipment manufacturer's name. The answer is relationships to get the right technology for your needs and the partner who will quickly fight for a good resolution to any problem,” Tomic says.

Automated, high-volume machining cell for soft milling and deep-hole drilling. Note the checkered flag themed flooring, symbolic of the checkered winner's flag.

These relationships are now how Eden Tool integrates technologies into their facility and manufacturing processes. Plus, they don't run technology out of the box. They modify technology, so how they use it is distinctly theirs. For example, they run their own macros to give them more control and better predictability.

Another example is the small Mitutoyo CMM with a Renishaw five-axis head Eden purchased and modified. “Someone could buy this same machine but not get the same outcome because of our modified parameters. You have to understand what's behind a piece of technology to make it work for you,” Eden says.

He notes that most people use CMM heads for speed and not accuracy, so most algorithms are for speed. However, for those in moldmaking, it's not speed, it's consistency and accuracy that matter, which makes it predictable.

Dave Tomic and Mike Eden explain the importance of the metrology department, including five-axis CMM, both for the certification of tooling components and validating molded parts.

Tomic advises to invest in technology and the process and then go one step beyond the superficial to achieve predictable manufacturing. That is exactly what he continues to do as Eden’s partner in Eden Manufacturing.

Organized Consistency

The key to this predictable consistency and performance at Eden Tool is hard milling. They rough fast and finish accurately. So what is predictable consistency? What are the factors? How do you manage it? Eden believes it's more than the operator. It's knowing the machine, the programming, the tooling, etc. It's everything. It's the whole process.

Examples of Eden’s next generation, both in equipment and toolmakers, taking the details of hard milling to the next level.

“Our first hard-milled mold was not medical; it was for a cap mold for a snuff tobacco can in 2008, and we hard milled everything,” Eden says. This job opened his eyes to the extreme nature of his team's capabilities.

When this customer ran the mold, they learned that every single cavity was consistent. “In this case, the differential between cavities was less than 1% because we hard milled everything — runners, cavities, etc. There was no handwork or polishing. The mold went directly into a vapor hone for finishing,” Eden says.

On top of the tolerance of a plastic part, there is also pressure displacement, as Tomic explains. A molder is trying to inject the same pressure displacement in the same timeframe between each cavity. So, it's not just about a tight cavity that does not flash; it's about leaking pressure — the same. If there is any difference, the result is cavity imbalance.

“It's all about consistency and becoming predictably consistent — from cavity to cavity and shot to shot,” Tomic says. “Then you start gettingbig-picture tooling benefits like interchangeable inserts as well as seeing other advantages. It all starts with predictable manufacturing from tool to product.”

Critical to efficiency and accuracy is modular fixturing and automation. Also note the laser tool probe and automatic part probe receiver shown. You can’t see the high pressure through-spindle coolant, the precision linear scales, or the cooling system for thermal stability, all for high precision. This four-year-old machine is a great reflection on the attention to details paid to the precision equipment as well.

It comes right back to cars. Winners in racing don't just build a fast car; that car has to run consistently. Consistency wins the race.

Hard Milling Success Translates to Molding Success

Today, they are applying predictable consistency to Eden Manufacturing. To the company, predictable manufacturing means doing proper development work and manufacturing engineering up front to work through the details and setting up a robust process. Ultimately, that means that they are on time with high-quality parts to the customer.

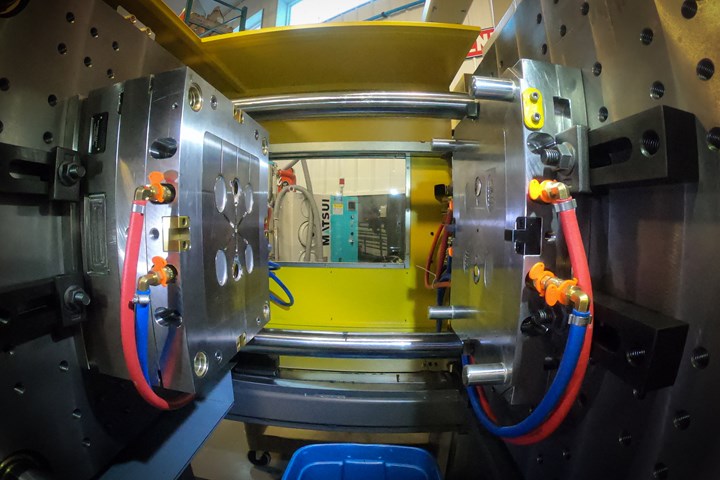

Eden’s latest investment is this new fully-automated plastic injection molding machine and the talent to use it to maximum advantage. David Tomic joined the Eden group in 2019 to form Eden Manufacturing, specializing in high-end medical molding, sampling, validation and metrology.

Back to Jake Eden. Remember, I mentioned earlier that Jake did not want Eden Tool, but was very interested in growing the company into an advanced medical component manufacturer instead, with dreams of his own medical line. This became Eden’s growth plan and legacy.

“I recognized that I'm not going to get to where we need to go by myself. I needed help,” Eden says. So, he continued talks with Tomic about molding, Swiss turning and production machining capabilities and created a high-level framework for a new company. They were looking in the same direction now, and it was time to fill in the details, but first, Eden needed to put some good people in place. He brought on Tomic as his partner in the newly-formed Eden Manufacturing, and they set out to broaden Eden’s current medical customer base.

As a result of COVID-19, medical manufacturers now need a redundant supplier base. As a matter of fact, redundancy will be part of every risk analysis moving forward, which means those manufacturers need more suppliers and will need to dish off smaller portions for risk aversion. And that's Eden Manufacturing.

“We're not a big fish, but we'll take their 15% risk analysis aversion, and by the way, we'll manage their tooling while we're at it. That's what we want,” Tomic says.

Another example of mold components, all hard milled complete, for critical shut-offs.

For example, Eden Tool builds the first mold for a customer that goes to the bigger molders to run 100 million parts. Eden Tool then builds a second, identical mold. They validate the first one and can now stock inserts for both molds for which they have the steel certifications. So, if a customer has a problem, they'll send another piece of tooling. The customer will not need to revalidate with a steel certification. Then the customer will give Eden Manufacturing 5 million parts a year to run off of the existing tooling to keep things rolling. Then 10 million parts a year. Eden Tool/Eden Manufacturing will be their redundant supplier.

Tomic is interested in growing both companies, and both Eden and Tomic understand they need each other. “Now, I have a succession plan, an exit strategy. Dave and Jake can take it over when I'm ready to retire,” Mike says.

Part of the Eden crew. Original employees alongside a new generation of plastic injection mold professionals.

Future Focus

Eden held off building the new facility because of COVID-19. Still, as much as he wanted to hold back on buying new equipment, he had to capitalize on the opportunities they saw for both companies.

Eden and Tomic have recognized an issue with high-end molding and high-end tooling support across North America. There is a capacity constraint and millions of dollars of investment. These companies are struggling with capacity to meet demand. Plus, this is not easy work. That is the type of work Eden and Tomic want — difficult parts and real problems to solve.

A current customer and other connections are already interested in using Eden to secure redundancy for intricate parts. They are struggling with high-end molding on high-end parts. High-end means critical components where failure has serious dollar value consequences, such as respiratory equipment. These are optically clear, polycarbonate parts that require light sensing to get blood discoloration spectrum readings, etc. It is not simple molding or fill patterns.

In the long term, within their new building, Eden Tool and Eden Manufacturing teams want to be designing and building the molds as well as complementary manufacturing processes to produce insert overmolded parts for emerging medical technologies. “Some of these parts are complex, and can be very difficult, but we want it! It's the future,” Tomic says.

Plastics is one half, metalworking is the other half, and combining them into insert molding is ultimately what Eden and Tomic want to do. It is all high-risk tooling that you can't offshore. They want the difficult stuff. They don't want the easy stuff.

The Eden Tool and Eden Manufacturing teams have work to do from an ISO and regulatory standpoint, but they have their eyes on the details to get there — medical device advanced manufacturing. So stay tuned!

Related Content

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreInnovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read MoreRead Next

MMT Chats: 5 in 5 with Eden Tool Company and Eden Manufacturing

MoldMaking Technology Editorial Director Christina Fuges reveals five best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive in 5 minutes with Eden Tool Company and Eden Manufacturing.

Read MoreICYMI--MMT Chats: Hot Rods, Performance, Predictable Manufacturing and Building a Legacy

MoldMaking Technology Editorial Director Christina Fuges chats with three team members of Eden Tool Company and Eden Manufacturing to learn the "details" about how this mold builder also became a manufacturer of engineered medical components. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMMT Chats: Relationships Are Key to Conquering Supply Chain Challenges

This mold shop owner built his shop with a focus on relationships, and this has become a clear advantage, as the industry works through the impacts of the coronavirus. Sit back and watch this MMT Chat as MoldMaking Technology Editorial Director Christina Fuges interviews two key members of the Eden team.

Read More