Doubling and Quadrupling Machining Speed, Capacity and Output

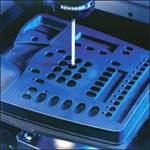

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

For over a decade, Prent Corporation was committed to one machine tool company to supply the vertical machining centers it needed to manufacture the cavity and plug assist tooling for its rigid plastic custom thermoform packaging. These parts supply a substantial percentage of the world’s packaging needs for leading medical device manufacturers.

Six Sigma manufacturing methods, and the company’s philosophy of capital reinvestment to not only meet but also exceed customer requirements, resulted in Prent researching how to improve its current capabilities and speed.

While they had long and faithfully invested in their former machine tool supplier, the machines were simply no longer able to keep up with the necessary demands, pace and quality requirements.

The Janesville, Wisconsin-based company does not make such major equipment or procedural changes lightly. Such moves come under close scrutiny, as guaranteed success is mandatory.

As the largest medical packaging thermoformer in the world, Prent strives for uniform processes and short tool and production leadtimes. They began an extensive research effort on what equipment should be acquired in order to surpass their critical customer requirements.

They looked to Makino to acquire multiple, high-performance vertical machining centers to achieve the rapid tool production time they needed. Prent has never looked back, and the change in machines has never been challenged. The results have doubled and quadrupled various production elements at the company.

With this acquisition, Prent has achieved a 60 percent reduction in run-time in its cavity and plug assist tool production. They also have dropped polishing time by 75 percent, and in many cases have eliminated it altogether.

“The added value that we offer via the Makino mills is tighter tolerances and improved speed,” says Jim O’Dierno, senior vice president of marketing. “Prent continually re-invests in leading technology and equipment to better handle the critical tolerances and market needs our customers require. This transition has helped us further distance ourselves from our competition.”

Global Growth

Prent Corporation started in Janesville in 1967, and they have grown to be a global operation of more than 600 employees, with facilities in Flagstaff, AZ, as well as Puerto Rico, Singapore, Shanghai and Malaysia. They also have a European alliance with Nelipak Thermoforming in Ireland and The Netherlands.

The company began making cake decorating kits and evolved into consumer product packaging. But due to market compression, they took the value-added skills and capabilities they had developed and moved toward dominance in the demanding and challenging medical and electronics industries.

The largest portion of Prent’s business is in medical and electronic protective packaging. They also produce packaging for the consumer and automotive markets. Much of this is cleanroom-based sterile packaging, with the company producing 100 percent of in-house prototyping and tooling to support its volume of thermoforming.

Precise flanges, sidewalls and corner radii are needed in this type of tooling, as cavity and plug assist tooling precision is essential in pressure forming plastic prior to it being cut, inspected, nested and shipped. This precise cavity and plug assist production, and the control of the negative and positive air pressure in the forming process, drives the production efficiencies and output.

Prent utilizes aluminum for its cavities and plug assist tooling, with molds up to 60 inches long and eight inches deep. They form products out of a variety of plastic rolls—including PVC, polystyrene, polypropylene, polycarbonate, barex, electronic, GOSTAT ESD, XT, PETG, APET and RPET.

Doubling the Tooling

Don Handrow, senior package designer at Prent, says the company is producing twice the amount of tooling with Makino than it had with its previous machine tools. “The S56 and V77 machines have allowed us to add capacity to build more tools. We went from two pieces of tooling built on the CNC to the capacity to build eight, with the extra mounting tools and fixtures formally done by hand now done on the Makinos.

“This results in quadrupling our capacity and output. Quite frankly, we were not expecting to see that. It ended up being such a huge advantage for us to have a machine that runs much faster and more efficient. It produces in six hours what used to take 23 hours, and reduces our labor costs.

“We wanted the higher capacity level and the durability provided by Makino,” adds Handrow. “I would not have been that comfortable buying into different advanced technology machinery if the machines were not high quality and durable. We were only getting a three-year average life out of our former CNC machines. With Makino, we plan to get 10 years out of each machine.

“We were walking before; now we are running. We invested in the training and technology to transition to Makino, which was an expensive transition for any company to go through. Prent has now learned the tooling, software, techniques and processes of high-performance machining from Makino.”

Exceeding Expectations

Handrow noted his primary goal in transferring to Makino equipment was to increase speed to better meet customer needs. Essentially, it was to do more work faster with the same amount of people—which would help eliminate escalating labor costs and better utilize those resources. He also was pleased to gain speed and performance in other areas, and exceed expectations for polishing, which often took as much time as the machining did.

“Recently, we had to replicate a mold that ran on a former CNC machine, which had taken 24 hours to manufacture,” Handrow notes. “We replicated it on the Makino V77 in six hours. That is a savings of 75 percent.

“We did not expect to see the high level elimination of machine marks or grooves that would have required polishing,” he continues. “This allowed us to trim 13 hours of fine, detail polishing down to four hours, far surpassing our expectations. We were told we could run Makino 24/7, which was very attractive and unusual for us. And we are pleased that Makino has proven to be able to handle that workload. Technical support is very good, both in person and on the phone, when we need them.

“We were challenged to try to wear the Makinos out, and it doesn’t appear to be possible as of today,” Handrow adds. “We are no longer running spindles at slower than their potential speed, having to monitor them for an extended period of time.”

Additional Benefits

“The level of accuracy that we are able to produce at Prent also has been enhanced,” says Handrow. “We are milling to 0.0001 and 0.0002 inches, which is unheard of in our industry. Many of Prent’s customers are locating around 150 to 160 datum points on these part finishes, and holding them at extreme CPK levels of accuracy. We were only able to handle 0.0005 inches of accuracy at best on our previous machines.

“The previous machine tools had large variations and limited repeatability. With the Makino machines a high level of accuracy and consistent repeatability is the standard,” says Handrow. “Our level of scrap with inaccurate molds and our time spent fixing the cavities and plug assist tooling has virtually been eliminated.

“We have been able to develop higher quality thermoform tooling, and to develop a system within our thermoform process for changing our tooling quicker,” he adds. “We see Makino as helping provide us with a 400 percent increase in our tool manufacturing.”

Handrow notes that Prent also is pleased with the space the Makino technology saves. “Prent operates in a cellular manufacturing fashion, with individual team leaders and designers who run two mills each. The space these pieces of equipment take up is so much smaller than our older equipment it helps us with our lean manufacturing principles.”

Programming Improvements

Another key time savings for Prent is in equipment programming. “Each part that we do is a unique part. We may only run three or four tool programs a day,” says Handrow. “We do not have any canned programs that we will run over and over again. So program and setup is unique, and we need to run fast to keep on top of our workload. We can better program now toward performance. We do not have to program the machine; we can program with the tool. This is something that we have not been able to do in the past.”

This performance enhancement by Prent is primarily due to the advanced control capabilities of the Makino Pro 5 high-performance control and the SGI.4 super geometric intelligence technology. It has cut post file run time from previous machinery by 75 percent.

Jim Appel, senior CNC programmer, says it would have normally taken him two to three hours to program the setting for a job on the previous machines. With the Makinos, that setup time is shortened to 30 minutes. “I am able to program and upload the settings from my office,” says Appel. “The Makino machines also enable us to save over 10 program settings in memory. So we can recall those settings at the push of a button instead of having to reprogram them.”

User-Friendly Results

Appel also notes the Makino control functions and user-friendly touch screens are much easier to understand. “Even our employees with limited Makino experience are easily handling the Makino machines,” says Appel. “They can’t comprehend life without the machines now because they are so much more efficient.

“From my perspective, there is no comparison between Makino and our previous machines; Makino is faster, better, stronger and has enhanced capabilities,” Appel continues. “The high level of Makino training, the remote download capabilities and memory settings, quicker setup and tool change times, machine rigidity and repeatability and the overall machine balance all make them far superior.

“We have programmers who are now true believers in Makino,” Appel adds. “There is a little bit more to learn, but it is easier to understand. And the touch screen capabilities are easy to follow. Once we program something, it is ready to go. Setup time is also a lot quicker, and the finishes achieved are superior. What Makino has achieved, and what we can achieve by using them, amazes me.”

“Prent is continuing to see a dramatic decrease in run time,” says Handrow. “On average, a mold that would have taken eight hours on our former equipment will now take three hours on Makino. The company is enjoying the benefits and rewards of having high-speed spindles running at capacity to achieve a real-time 400 ipm on the S56 and 700 ipm on the V77. Makino is just a different animal than anybody else in the industry.”

Handrow notes, “Our customers say, ‘We need it and we need it now.’ The investment we made in Makino results in our ability to respond quickly to those customer requests. I am pleased that our transition to Makino has made such a big impact for our customers, and on Prent Corporation.”

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreOvercoming Barriers to Automation Integration in Precision Moldmaking

It’s easy to imagine the advantages automation offers the moldmaking process, but it's challenging to change one’s mindset, develop a plan and invest.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreRead Next

How to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)