From the Field

Keeping an edge over the competition.

One of the fastest growing materials in the medical implant market is polyetheretherketone (PEEK), an organic polymer thermoplastic. This material is highly resistant to thermal degradation and attacks by both organic and aqueous environments, making it ideal for orthopedic implants. However, many manufacturers are reluctant to mold PEEK parts due to the difficulties associated with the material during the molding process. This is what puts Plastic Design Corporation (PDC) ahead of the competition.

By using advanced processing methods and sophisticated micro-molds, PDC has successfully molded several highly complex PEEK projects. To obtain the ultra-high precision necessary for PEEK micro-molds, PDC relies on several high-performance machining centers from Makino.

To demonstrate their PEEK machining capabilities, PDC recently designed and produced a medical fixating device mold featuring several sharp barbed edges. Because the application of this part requires fixation to bones and ligaments, PDC was faced with the challenge to make each barb as sharp as possible while using injection molding.

“The traditional way of producing PEEK parts for implantable components is to machine them out of raw stock; however, at approximately $2,000 per kilo, this can result in some expensive waste,” says Mark Kinder, owner of Plastic Design Corporation. “To avoid this waste, we wanted to produce the part through an injection molding process, which would only use enough material to complete a net part. In doing this, we would produce a fraction of the waste while simultaneously reducing our cycle times for each part.”

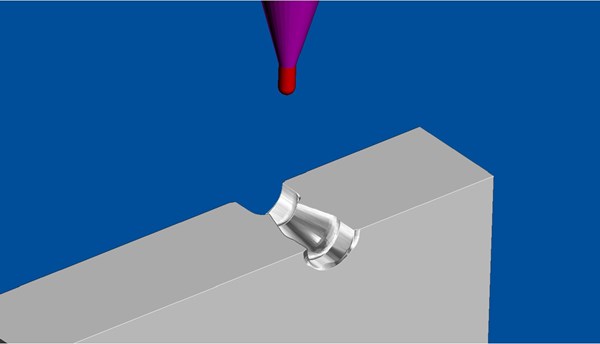

The benefits of injection molding this type of application are counteracted by the difficulties in creating sharp edges and corners via EDM, the most common practice for producing solid mold blocks. With EDM, even an electrode with crisp edges can produce corner radii only as big as the offset of the spark gap, oftentimes causing soft radii to be produced. And even if a solid mold block features perfectly sharp corners, the plastic wouldn’t completely fill the edges due to surface tension in the injection process.

“By producing a solid mold block using EDM, the best corner radii we could produce would be just under 0.001 inch, and even that requires some fairly sophisticated orbiting,” says Kinder. “In order to injection mold these parts with the required specifications, we had to take a different approach to how these mold blocks were produced.”

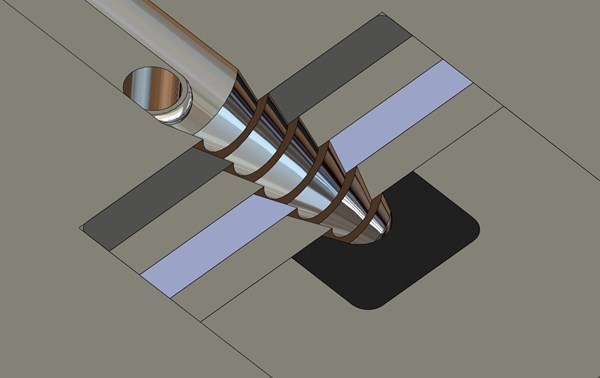

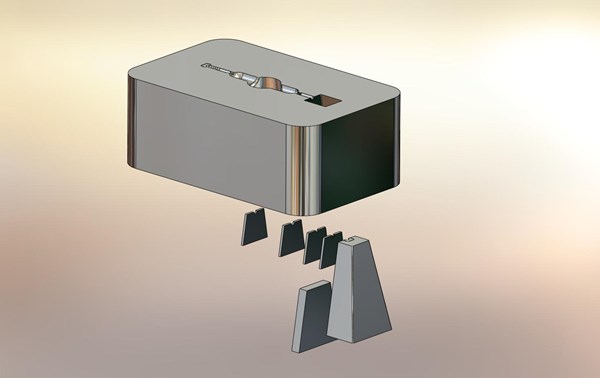

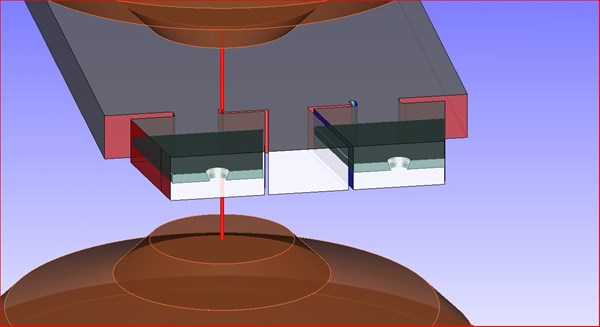

PDC’s solution to this issue was the development of a six-layer laminated mold cavity. The extremely thin space between each lamination would provide an escape for heat pressure created during the injection process, enabling the plastic to fill out to every edge of the mold. This cavity was created as half of a two-cavity mold that also featured a cavity burned solid on a sinker EDM using a barbed electrode. With this solution, the company would be able to measure their success against standard practices.

The accuracy requirements for each lamination demanded extremely tight tolerances due to PEEK’s ability to flash at 0.0003 inch. To meet these requirements, PDC used a Makino V22 vertical machining center to hardmill the conics of the barbs and an U32j wire EDM for finishing.

“It would be incredibly difficult to surface grind a 0.01-inch-thick lamination,” says Kinder. “EDM offers a lower stress environment where we can cut the lamination thickness down from 0.040 inch to 0.01 inch worry-free.”

Each lamination featured tapers for self-centering to locate and position them appropriately within 0.000050 inch. Once the laminations were stacked together, a larger end block featuring tapers on three sides was used to create a lateral thrust load, firmly squeezing all the laminations together. The resulting space between each lamination ranged between 0.000050 inch and 0.0001 inch, allowing just enough space for gas to permeate for a crisper edge to the barb.

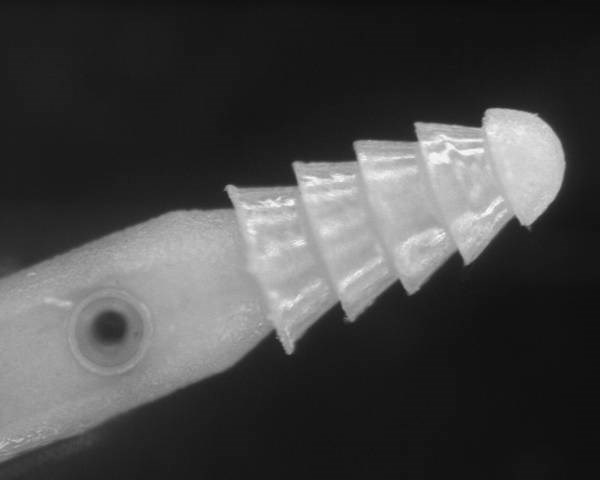

The final parts were compared under a microscope to observe any noticeable differences in quality. PDC came to the conclusion that surface quality, edge thickness and corner radii showed dramatic improvements under the laminated cavity, fulfilling their demands for crisper, sharper barbed edges.

“This project was not an easy process but has become an exemplary piece for the capabilities we have here at PDC,” says Kinder. “Our knowledge and expertise combined with high-performance machining capabilities from Makino give us the edge we need to stay one step ahead of the competition even in the most difficult applications.”

Related Content

The Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

New Business Opportunities: New Equipment Investment Solidifies Medical Mold Prototyping Niche

Investing in an additional high-speed machining center and converting to electric presses rather than hydraulic has allowed mold manufacturer/molder Injection Mold, Inc. (North Vernon, IN) to step up its game by speeding up already quick delivery times.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More