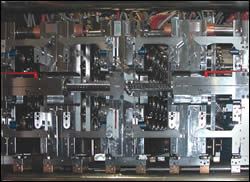

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

The ability to develop high cavitation molds for thinwall parts is a growing requirement for moldmakers in the medical market. With product cost as critical to design as performance and functionality, medical OEMs and the companies that supply them look to save as much money as possible when specifying parts. Two of the most important areas for this are materials and productivity: reduce the first and increase the second, and costs come down.

Toolmakers, consequently, report growing demand for molds that produce thinner parts in greater volume. “Part costs are thinning parts out, almost to the point of failure,” says Tony May, Technical Sales Director at Pyramid Mold & Tool (Cucamonga, CA). “This has been going on for years, but lately it’s more prominent.”

The trend isn’t limited to any class of products—most, even the lowly emesis basin, are being aggressively downgauged and molded in as many cavities as feasible. It’s not uncommon, moldmakers say, to have customers with four-cavity molds request quotes for 16-cavity tools. And that’s at the low end of the multi-cavity scale. Jordan Robertson, General Sales Manager a stack mold specialist StackTeck (Brampton, ON), says his company produced a 2x32 mold for a disposable medicine cup 1.75 inches in diameter by 1.25 inches high and 0.0015 inches thick. High-volume output coupled with material reduction gives the molder enough margin to be profitable.

StackTeck has notched impressive developments in high cavity molds. The company unveiled last year a 4x32 mold that Robertson says is the highest-cavitation stack mold ever made. Though developed for three-inch lids and not medical parts, engineering features of the 35,000-pound tool have much in common with those of multi-cavity medical molds—one of which is designing the tool to operate at the same fill speed and cycle time as a smaller, less complex mold. Robertson says all four stacks fill in 0.25 seconds. Depending on lid thickness, cycle time is between 5.5 and 7.5 seconds.

The mold can achieve these process times because of recent advances in injection machine design, especially large-tonnage presses. “As cavitation increases, you don’t have the flexibility with thin parts to extend fill time because the injection machine can’t keep up. Thin parts will freeze off,” Robertson says. “The demand [for high cavitation molds] is there and the machinery builders are increasing their ability to fill large shots.”

The focus on materials reduction and productivity presents numerous challenges to moldmakers. Thinwall parts require high injection pressures. Produce them in molds of from 16 to 128 cavities and the engineering problems increase. These include assuring precise alignment in how a mold and its components come apart and go back together; balancing a hot-runner system; optimizing thermal characteristics to maintain resin integrity over long flow lengths; designing an appropriate cooling system; balancing flow requirements with fast cycle times; and synchronizing mold operation with robotic handling equipment—all of which has to be done while working with a large and heavy mold.

“And, of course, you have to have bulletproof repeatability with respect to being able to mold the same part to extremely fine tolerances in every cavity,” says Robertson. This is especially true when part volumes run into the tens of millions—as with devices like syringes, pipettes, needle shields and luers.

Moldmakers, of course, have their own techniques for optimizing the design of high cavitation molds. May cites one area of Pyramid’s expertise: thermal management. “We try to design with as much cooling as possible.” The key to this is water flow and back pressure. An incorrect calculation of either, especially in a large mold, will result in a process that falls short no matter how well designed a mold is, he says.

A toolmaker’s proprietary techniques can be enhanced by continuing developments in equipment, components and materials. Following are examples of products that suppliers say will optimize the development and performance of high cavitation molds.

Machining

No matter how complex or precise a mold is, the market still wants an economical mold build process with short leadtimes. A number of machining suppliers cite features that achieve this.

Moldmakers wanting an EDM unit with microfinishing capability might check out the FA-PS wire machine from Mitsubishi EDM (Wood Dale, IL). A replacement for the company’s FA-P series, the unit has a wire diameter range of 0.002-0.012 inches, says Greg Langenhorst, Technical Marketing Manager. The fully automated unit offers precise positioning of workpieces and digital controls for cornering accuracy and other functions. It can simultaneously machine pieces of different size and weight.

Langenhorst says an important feature of the FA-PS model is an internal cooling system that assures thermal stability and thus process accuracy. It is based on the cooling system of Mitsubishi’s MA2000 die sinker EDM, an ultra-high-precision model that reportedly holds tolerances of +/- 0.002mm.

Much larger workpieces are fabricated on the Exeron die-sinker EDM from Methods Machine Tools (Sudbury, MA). The machine comes in six sizes. The largest, the 316 XXL, has a travel range of 70.8 by 45.2 by 23.6 inches (X, Y, Z), handles workpieces up to 13,227 lb., and electrodes to 1,100 lb. Standard features—many of which Methods Machine Tools claims are options on competitive machines—include a granite worktable, automatic rise-and-fall fluid work tanks, chiller, cartridge-free reflush system, automatic lubrication and a carbon dioxide fire-suppression system.

One of the newest vertical machining centers from Makino (Mason, OH) is the V22, which Marketing Manager Mark Rentschler says is suitable for high precision finishing of small, complex molds. The unit mills intricate cores and cavities with a 40,000-rpm spindle that operates with a high degree of accuracy. As an example of its precision, all full-stroke axes of motion are guaranteed to deliver levels of straightness and perpendicularity within 3 microns.

The V22 has travel of 12.6 by 11 by 11.8 inches (X, Y, Z). The work table is 17.7 by 13.8 inches. The machine can handle a 220-lb. workpiece, and the maximum tool weight is 1.1 lb. Rapid traverse is 787 ipm, and the cutting feedrate is 394 ipm. A 30-tool changing system is standard, and a 60-toolchanger is optional.

The UPZ-210Li profile grinder from Okamoto Corp. (Buffalo Grove, IL) is described as a high-precision unit that reduces part handling, process inaccuracy and cycle time. Victor Truelsen, Technical Sales Engineer, says that although the wheel runs at a relatively slow 3,600-8,000 rpm, the UPZ has a high speed reciprocation motor that achieves 300 strokes per minute. The high stroke count gives the machine greater accuracy, especially in forming cavities with tight tolerances, than high rpm systems that remove larger amounts of material with every pass. The grinder’s speed prevents heat buildup and minimizes wheel wear.

A key feature of the 210Li is an internal CCD camera that measures a workpiece in the machine. Truelsen says a CAD image can be overlaid on the part to compare dimensional data. Removing the workpiece for inspection offline and reinserting it can affect wheel and part alignment and grinding accuracy. Reduced part handling also speeds the process. Designed for small pieces like mold inserts, the grinder has a 6.8- by 4-inch chuck area and an 11-lb. table capacity.

Haas Automation (Oxnard, CA), meantime, touts its VM-6 vertical machining center for milling high cavitation molds. Features include an inline, direct-drive spindle that reduces heat generation, and a choice of three spindle speeds—18,000, 24,000 and 30,000 rpm (see Packaging Molds Go High-Tech to Improve Productivity and Economy).

Software

Enabling many of the advances in milling systems is software, specifically CAM programs that translate design data into cutting commands. Among developments in this area is TrueMill from Surfware Inc. (Westlake Village, CA).

Developed for CNC milling machines, the software uses a special technology to control a two-axis cutting tool’s “engagement angle” with metal, says Glenn Coleman, Vice President of Product Design. The result is that the cutting tool is never overloaded, and related machine operations like spindle speed, feedrate and depth-of-cut proceed in a smooth, trouble-free manner.

TrueMill can cut a range of intricate shapes. The guaranteed strain-free toolpath is said to significantly increase feedrates and reduce tool wear.

Components

There are a number of ways toolmakers achieve the high part tolerances medical molding demands and optimize functions of high cavitation molds. Many of these are found in offerings from component suppliers.

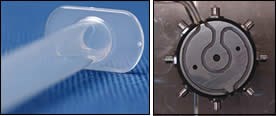

The Melt-Disk from Mold-Masters Ltd. (Georgetown, ON) is a circular manifold for edge-gating parts. Each disk molds eight parts. When mounted in a mold, an array of Melt-Disks can be used to create up to 192 cavities. Ideal for small, thinwall parts like pipettes and syringe shields that can’t be molded through the center of a cavity, the device processes most commodity and engineering resins, says Neil Dewer, Senior Technical Liaison.

Thermal control is critical to process efficiency. Even heat profiling is maintained during injection with hot runner components from D-M-E Co. (Madison Heights, MI). Stellar micromolding nozzles, designed for thinwall parts, have low conductivity heads and high conductivity tips to regulate heat, says Robert Starr, Global Marketing Services Director. Galaxy manifolds distribute heat and balance flow as a means of maintaining pressure drop, shear rate and residence time within preset limits. Galaxy nozzles, meantime, have tips made from a highly conductive metal that transfers enough heat to reduce gate vestige and assure part aesthetics.

Some molds, because of part geometry or other reasons, use cold runners. For moldmakers who prefer to install hot runners, Incoe Corp. (Troy, MI) may have an answer. The Micro Multi-Tip nozzle adds flexibility to mold design by permitting close placement of hot runner nozzles within a tool. According to Jim Bott, North American Sales Manager, pitch dimensions go as low as 6mm. Nozzles can be specified with two to six injection points within a 12mm gate circle.

A line of Roller Pullers from Progressive Components (Wauconda, IL) controls the opening sequence for parting lines. Designed as replacements for mechanical latch locks, the devices are made with a “friction-free” metal so they can be used in cleanrooms where external lubricants are not permitted, says Glenn Starkey, President.

The products have “sight windows” that allow adjustment of their pull force, and industry-standard mounting patterns. They are reportedly easy to install and designed to last for more than one million molding cycles.

The pullers can also be used to pull or retain double ejector plates and other floating mold plates.

The growth of high cavitation medical molds is bound to have builders of stack molds taking another look at the Split Sprue Bar from Husky Injection Molding Systems (Bolton, ON). The device—for two-, three- and four-level versions—seals itself off and splits at the parting line when the mold opens, says Bill Gunn, Market Manager for Medical. In contrast to full sprue bars, this provides unimpeded mold access. As a result, robotic part removal is facilitated, along with gravity drops, since there are no heated parts of a sprue bar in the mold opening to impede such operations.

Surface Treatment

Coatings are usually viewed as a way to improve mold hardness or achieve chemical or corrosion resistance. One company is promoting a coating as a means of reducing cycle time. Bales Mold Service (Downers Grove, IL) offers Nibore, an electroless nickel phosphorous coating that provides a high degree of lubricity, as well as abrasion and corrosion resistance, and hardness.

Steve Bales, President, says the material has an extremely low coefficient of friction. When applied to a mold, this yields a substantial improvement in the release characteristics of the mold halves, which reduces pressure and lowers cycle time. Bales estimates that a 32- or 64-cavity mold coated with Nibore could achieve a 6 to 8 percent reduction in cycle time. The material also achieves a 54 Rockwell hardness rating, which increases to 67 after heat treatment, a level just below that of chrome.

Summary

The trend to high cavitation molds for medical parts reflects the large and intensely competitive nature of the sector. With a U.S. market valued at around $80 billion in 2006, annual growth of 8 to10 percent, and a viable export business, there are plenty of opportunities for companies with the vision and discipline to be part of the market, and the skills and stamina to compete.

Patrick A. Toensmeier has been writing about the plastics industry for 20 years. He can be reached at toensmeier@sbcglobal.net, or visit www.moldmakingtechnology.com anytime.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Medical: The Right Rx for American Tool Builders

When technology, quality and speed step to the fore in the medical world, so does the North American mold and die industry with some innovative products and processes.

Read MorePackaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More