RJG Inc.

3111 Park Dr.

Traverse City, MI 49686 US

231-947-3111

info@rjginc.com

rjginc.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

RJG Inc. Supplies the Following Products

- Consulting Services

- Pressure Controls, Sensors, Monitors

- Process Controllers

- Training and Workforce Development Services/Software

- Valve Gate Controllers

Trade Names Offered by RJG Inc.

Editorial, News, and Products

-

2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

-

State-of-the-Art Machines, Custom Manufacturing to Reduce Injection Molding Waste

NPE 2024: Sodick-Plustech and more than 20 vendor partners are demoing five injection molding machines, in addition to dryers, loaders, robots, molds, temperature control units, materials and more.

-

Educating the Next Generation of Plastics Professionals

These schools and local industry are working together to close the workforce gap in the plastics industry by offering hefty plastics curricula and training programs for degree-seeking students as well as current plastics employees looking to upskill.

-

Smart Assistant Bridges Injection Molding Skills Gap

NPE2024: MAX the Process Advisor, as well as free presentations and training by RJG Inc.

-

Intelligent Equipment Solutions Alleviate Moldmaking Pain Points

Whether it’s purchase quoting, mold cleaning and tracking or intuitive process control, the following new or improved technologies could potentially keep your shop on the cutting edge.

-

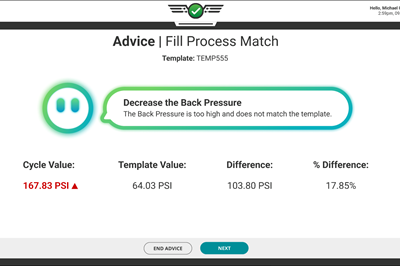

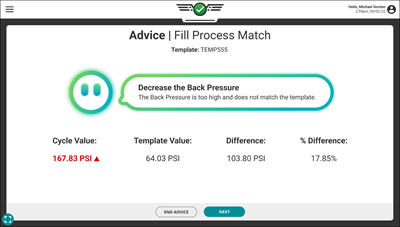

AI Augments Injection Molding Process Control System

MAX, a new process advising feature added to RJG’s Copilot system, is engineered to help troubleshoot and optimize the injection molding process and addresses industry skill gap.

-

Free, Assisted Data Transfer for Injection Molding Monitoring and Control Platform

For a limited time and free of charge, RJG will help users of its eDart platform transfer data to its CoPilot system using a new data migration tool.

-

RJG Announces 2023 Qualified Trainer of the Year

Craig Potthast of Central Community College is recognized for his dedication to a molding education.

-

Annual RJG Global Mold Smart Award is Now Open for Applications

Potential 2024 award candidates are dedicated to transforming their injection molding company using RJG technology or service solutions. Applications are due by Dec. 31, 2023.

-

Editorial Advisory Board 2023-2026: Meet New Board Member Adam Nartker, Diversified Technologies International

The 2023-2026 version of MoldMaking Technology’s EAB features a new crew of industry professionals. Meet Adam Nartker.

-

RJG Inc. Adds LS Mtron WIZ-55E Molding Machine to North Carolina Training Facility

Partnership brings cutting-edge training in scientific molding to RJG’s new facility to further develop future workforce skills.

-

“Graph Interpretation for Injection Molding” Course Available to Moldmakers

The new three-day RJG course offer classroom-style learning and hands-on applications for technical and non-technical personnel. The first course is to be held Dec. 13-15, 2022.

-

Technology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

-

Free Injection Molding Training, Hands-On Demonstrations

Visit RJG’s booth at the K Show to watch training segments from its trainers worldwide, receive hands-on demos of the CoPilot system and view the power of The Hub networking system.

-

RJG Appoints New CEO

After 24 years at RJG, Dale Westerman has begun the transition to retirement as he hands off the reins to incoming CEO Rob Nugent.

-

RJG Announces Winners of Inaugural Mold Smart Award

RJG’s Mold Smart Award celebrates injection molding companies that have fully committed to improving the quality of their products, lives and the world by implementing a variety of RJG solutions.

-

Online, Self-Paced Injection Molding Training Course Bridges the Skills Gap

RJG releases the “Essentials of Injection Molding” eLearning course. Portioned out into digestible segments, it can help new hires efficiently familiarize with industry terms and foundational concepts.

-

Injection Molding Process Control System Provides Traceable Data and Valve Gate Control

RJG showcases its CoPilot injection molding process control system, which is said to be user-friendly and enable users to collect traceable process data and now includes valve gate control.

-

Injection Mold Networking Software Application Reduces Mold Transfer Inefficiency

The Hub for Mold Transfer offered by RJG facilitates standardized processes, improves organizational efficiency and ensures proper mold and machine matching across global facilities.

-

What Is the Difference Between Knit and Meld Lines and Why Does It Matter?

Three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Meld and knit lines are actually both different types of weld lines. Here is a look at the differences between them, the causes of meld and knit line imperfections, and their impact on part durability.

-

5 Questions to Ask Before Instrumenting a Mold

Instrumenting an injection molding machine with sensors can be a daunting task. It is a huge investment, after all, so how do you ensure that it will pay off in the end? The key is knowing the right questions to ask before you even begin. Here are the 5 most important questions to ask in chronological order.

-

RJG Germany Opens Injection Molding Training Facility

RJG Germany GmbH opened the doors to their new training lab on January 1, 2020.

-

How to Use a Conformally Cooled Sprue Bushing to Reduce Cycle Time and Ease Cost Pressures

Use of a new conformally cooled sprue bushing helped solve Midwest Mold Services’ problem with a big sprue that was hard to cool and preventing faster ejection times.

-

Cavity Pressure Sensor Ideal for Tightly Packed Ejector Pins

RJG releases a 250 lb 6 mm cavity pressure sensor ideal for high cavitation molds with small, tightly packed ejector pins so users can measure cavity pressure in order to improve quality and reduce costs.

-

Noteworthy News: Teaming Up

Catch up on the latest business partnerships within the moldmaking community from Hurco Companies, Inc., iD Additives, Inc., PCS Company, RJG and HRSflow.

-

Tech Trends: All the Small Things

These products from RJG, Tungaloy, Rhino Products, LLC, Walter and Gesswein are designed to fit within moldmaking processes.

-

Noteworthy News: Weekly Wrap-Up

There’s always something interesting going on in the moldmaking industry. See the recent news releases below from iD Additives, Ingersoll Machine Tools, RJG, and more to see current happenings for this week!

-

Partnership Advances Process Control Using In-Mold Sensors

RJG and HRSflow have partnered up to provide an advanced process control solution, specifically for servo valve gate technology or independent cavity control.

-

The Effect of Pressure and Temperature on Part Quality and Dimensions

Injection molding is a complex system of machinery, fluid dynamics, and thermal conductivity. And that’s just the tip of the iceberg. Let’s simplify it. Let’s break the mold down into two simple parts, the heat exchanger and the pressure vessel, and review how they can impact overall part quality and dimensions.

-

The Plastek Group Wins RJG Training Excellence Award 2019

RJG announces The Plastek Group as the 2019 winner of the Training Excellence Award.

-

Noteworthy News: Develop Your Skills

These recent news releases present a wide range of options for industry education, from courses both in classroom settings or online to earning credentials to networking events.

-

RJG Partners with Central Community College, Opens Training Facility

Central Community College (CCC) and RJG have partnered to bring injection molding training to Nebraska.

-

Injection Molding Simulation Prediction vs. Actual

Simulations have come a long way in the last three decades, but if we seek to prevent dimensional variation, we must understand what provides the highest level of accuracy so we can make good injection mold engineering decisions.

-

A 'Quality Without Compromise' Mindset and A Diverse Customer Base Gives Delta Mold More Peaks Than Valleys in Business

Quality-driven processes and focus on diversity in the markets served are key to Delta Mold’s continued success.

-

Incoe Celebrates Its New Global Headquarters

Hot runner supplier hosts open house in Auburn Hills, Michigan.

-

Engineering-Driven Mold Builder Specializes in Difficult One and Two Shot Molding Applications

Ameritech Die & Mold continues to be an engineering-driven builder of complex, one and two shot molds.

-

2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

-

RJG Opens Training Facility in Mexico

RJG opens a training facility in Mexico in partnership with Yanfeng Global Automotive Interiors.

-

RJG Students Receive Consignment Machine from Maruka

Maruka USA recently consigned an FCS HA-65SV injection molding machine to an RJG training facility.

-

RJG Partners with SA Engineering

RJG partners with SA Engineering to offer students an additional location to attend the company’s injection molding training courses as well as a place to test out its equipment.

-

Redefining Learning Labs

Training facility partners with a local North Carolina community college to challenge advanced manufacturing students to design parts, which will then be converted into mold designs for the training facility.

-

Proprietary Systems and Expertise in Rubber Gives Roembke Mfg. and Design a Global Footprint

From the very beginning, Roembke Mfg. and Design has engineered and built molds for rubber products while also developing proprietary solutions for customers worldwide.

-

RJG Receives Machine from Maruka

Maruka has consigned a 65-ton servo hydraulic molding machine to the RJG hangar lab.

-

RJG Technologies Wins Best Business Initiative

RJG Technologies wins Plastics Industry Award.

-

RJG Awarded Niche Training Consultancy of the Year

RJG received an award in recognition for the quality of their courses and apprenticeship training.

-

RJG Receives Consignment Machine from Krauss-Maffei

RJG students will be able to interact with the machine in a variety of ways in order to put into practice what they learned in the classroom.

-

Designing Injection Molds to Meet Validation Requirements Without Rework

In injection molding, fixing molds that produce nonconforming parts is an expensive proposition. Here’s how to design and build tools that produce good parts from the start.

-

RJG and Key Up Education Offer Field Trips

Third graders enjoyed field trips to an injection molding lab, allowing them to connect with math and science in the real world.

-

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

-

Technology Tuesday: Preparing for NPE with Plastics Review

This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic.

-

How to Proactively Engage Educators with Plastics

RJG Inc. participates in Tuesdays for Teachers initiative to further engage educators with plastics industry career opportunities and STEM teaching resources.

-

RJG Hosts Teachers at North Carolina Facility

The “Tuesdays for Teachers” program at RJG brought local teachers into the discussion on getting high school students interested and involved in technical and manufacturing fields.

-

Limiting Stress Limits Chances of Plastic Part Failure

Molders can reduce excessive stress in plastic parts with a deeper understanding of part design, mold design and material selection.

-

Collaboration Key to Completing Puzzle Mold for Training

Collaborative manufacturing is what helped make an apprenticeship training program and a scientific molding training program come together in the form of a puzzle mold on July 21.

-

Getting Keyed Up About Math with Injection Molding

Starting kids' love of math and other STEM-related curriculum in grade school is what everyone agrees needs to happen so that they will gain an appreciation for careers in manufacturing. Mary and Marty Key are doing it.

-

Cavity Pressure Selection Options and Solutions

According to RJG Consultant and Trainer Shane Vandekerkhof, whether you are a first-time user or a seasoned veteran, cavity pressure selection and placement can at times be a confusing decision. Here is a look at the options available to fit your application to make you successful.

-

Study Shows Advantages of Mold Heating and Cooling Technologies

RocTool, a developer of mold heating and cooling technologies, shares the findings of a study it conducted to identify a range of resin materials that successfully use RocTool’s molding technologies to produce high-quality parts with high flow and reduced cavity pressure.

-

Third Graders Becoming Molding Experts?

Third grade students from Chatham Charter School got energized and inspired during a day of learning and real world problem solving in injection molding at RJG's North Carolina facility.

-

Technology Tuesday: Hot Runners and Mold Components

This week’s Tech Tuesday blog brings readers a review of several products announced during the last few weeks, namely hot runner and mold componentry.

-

SLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

-

Enhanced Decision-Making

Collaborative manufacturing, combined with systematic injection molding training, can help reduce the costs and time associated with design for manufacturing.

-

The Power of Knowledge

Although technology is the main draw at a show like NPE, equipment and process carry an operation only so far. Here are a few new initiatives in industry education.

-

Molding the Future with 3D Printing

Dubbed the 3D Printer Project, three groups have come together in the hopes of generating interest and awareness of STEM education opportunities for educators and students.

-

Advanced Process Monitoring and Control System

eDART

-

Easy Interface on Process Control Monitoring System

eDart.

-

The Evolution of Process Training for Mold Builders

Process training coupled with cavity pressure data provides mold builders with value and information that can be passed onto customers.

-

Electronics Market Needs Complex Molds Fast

Meeting the stringent requirements in the electronic/electrical products market improves moldmaker’s overall processes.

-

Extreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

-

Setting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

-

Mold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

-

Understanding the Effect of Pressure in the Cavity

Molders offer a moving target for moldmakers to adjust to by producing parts with different cavity pressures.

-

Has the Molding Machine Been Tested?

Knowing how a machine is tuned will improve your decision making for mold construction and adjustments.

-

Part Two of a Two-Part Series Valve Gate Sequencing Strategies

More valve gate strategies and how they help moldmakers and molders work together to develop a mold that will provide the most consistent performance.

-

Part One of a Two-Part Series Valve Gate Sequencing Strategies

Ways to use valve gate control strategies to improve quality, efficiency and profitability

-

Multi-Process Disease In Hot Runner Molds

Multi-process disease is a complex interaction between the mold, the manifold, the material, the machine and the mold temperature controller.

-

Post-Show Highlights — The Need For Speed

The show's racing theme was no accident as exhibitors and presenters showed the latest products, equipment and strategies designed to speed up the mold design and build process so moldmakers can win the race for better leadtimes.

-

Is the Part Design Good?

Basic part design is always a concern and is the starting point for a robust process that is profitable.

-

Rigorous Mold Tryout: Do Your Homework

If moldmakers strive to understand how an end user will use the mold, they will help their customers become more profitable and more confident in the shop’s abilities leading to a strong partnership.

-

Ready-To-Go Molds

By properly designing and building molds that are ready-to-go, moldmakers can shorten leadtimes and stay competitive.

-

Adding Value to Your Mold

Moldmaking shops must evaluate the need for a pressure transducer in an injection mold to assist them in gaining valuable information as the mold is developed.

-

Designing Molds That Work for You

Mold design approaches include full 2-D, a combination of 2-D and 3-D, and full 3-D.