Enhanced Decision-Making

Collaborative manufacturing, combined with systematic injection molding training, can help reduce the costs and time associated with design for manufacturing.

Today more than ever, OEMs are demanding increased supplier involvement earlier in the product development process. Collaborative manufacturing, in which all players work together to produce the end product, is one approach to meeting this demand. It provides a framework for sharing information between engineering and manufacturing in reviewing part design; and for simulating, optimizing and assessing the mold development process to avoid molding uncertainties. It also serves to educate all players about certain aspects of the process.

Making changes further down the line in the tool-launch process is expensive, so it is important to catch any necessary adjustments early and introduce the new mold using a documented, scientific plan. Hope is no longer an adequate strategy for a successful mold launch. Within the OEM, collaborative manufacturing requires early involvement of and transparency among the quality, design, material, tooling and manufacturing departments, because in almost all cases, concession made throughout this process by one affect others in the process chain. Decisions cannot be made unilaterally; they must be collaborative.

General collaborative exchanges between departments or among the various links in the supply chain should include performance specifications (key characteristics, dimensions); material selection (amorphous or crystalline, filled or nonfilled); part design (nominal wall, moldability); mold design (draft, slides and lifters); machine selection and performance (barrel capacity, speed, pressure); and process sustainability (decoupled molding and process control). Yet oftentimes there are silos or geographic distances between these functional groups, and “throwing it over the wall” to the next department is not a strategy for success.

At the root of collaborative manufacturing is education and training among these departments. This improves communication and data-driven decision-making, leading to a better process flow. The first step in this endeavor is looking at the molding process from the plastic’s point of view, so to speak, which entails systematic injection molding training. This training should include four key principles related to the molding process that will serve as the building blocks for every collaborative exchange in the process chain:

1. Heat – preparation of the plastic for the next shot (melt, residence time, barrel capacity).

2. Flow – introduction of the plastic into the mold cavity (alignment of polymers, shear rates, speeds, consistency).

3. Pressure – compression of the plastic into the cavity and length of compression.

4. Cooling – dispersion of thermal heat/energy out of the part and into the mold through the cooling channels (design and alloy options).

Such training provides a better understanding of how to develop a machine-independent process, how to make data-driven improvements to existing processes, and how to troubleshoot effectively using scientific and systematic approaches. It also teaches the cause-and-effect relationships among the machine, process, mold and material, as well as the influences of polymer behavior. Once this training is complete, a specific training plan based on job function and assessment test can be determined, which might include, for example, strategies for tool launch, part design or customized workshops.

Systematic injection molding training helps create a common language among those in the process chain, easing discussions over questions such as: Why did you gate into that thin section? Why did you add those ribs? Why are you changing the material? Prior to this collaborative training approach, common responses to these questions might be: “We copied the feature from the other design,” “We are not sure we need to have all those ribs,” or “It worked at tryout, but we can’t make parts in the home press.” The point is, collaboration at all levels gets everyone on the same page with a common level of understanding.

Take for example, a company that experienced a successful design, mold build and tool launch, despite the fact that the performance specification for airflow was not included from the beginning. This oversight would have been caught if the quality department had been engaged beyond providing dimensional criteria. Because it was not, however, a second mold was required to replace the one that failed the performance specifications.

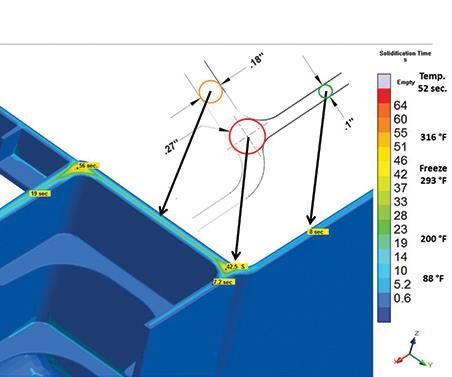

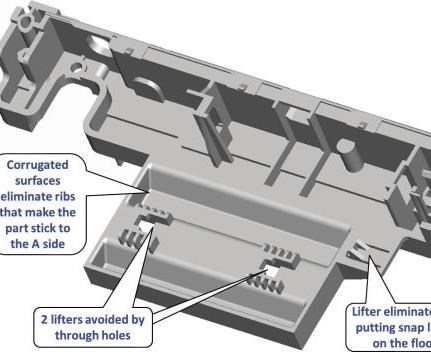

Another case (see example on page 51) involved a company with solid collaboration between its part and mold designers that prompted a negotiation with the design group to eliminate a lifter in a difficult spot. This collaboration also resulted in the use of conductive alloy inserts to reduce thermal distribution, which had a significant impact on cycle time and warp. These decisions were not made unilaterally, but by a team.

One essential point in collaborative manufacturing is this: Trade-offs will often be required when changes are made, but the trade-offs up front will allow strategic decisions to be made later. A collaborative manufacturing approach with some system-atic injection molding training is a long-term strategy that should not only increase margins, but reduce headaches.

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreRead Next

Molding the Future with 3D Printing

Dubbed the 3D Printer Project, three groups have come together in the hopes of generating interest and awareness of STEM education opportunities for educators and students.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More