Getting Keyed Up About Math with Injection Molding

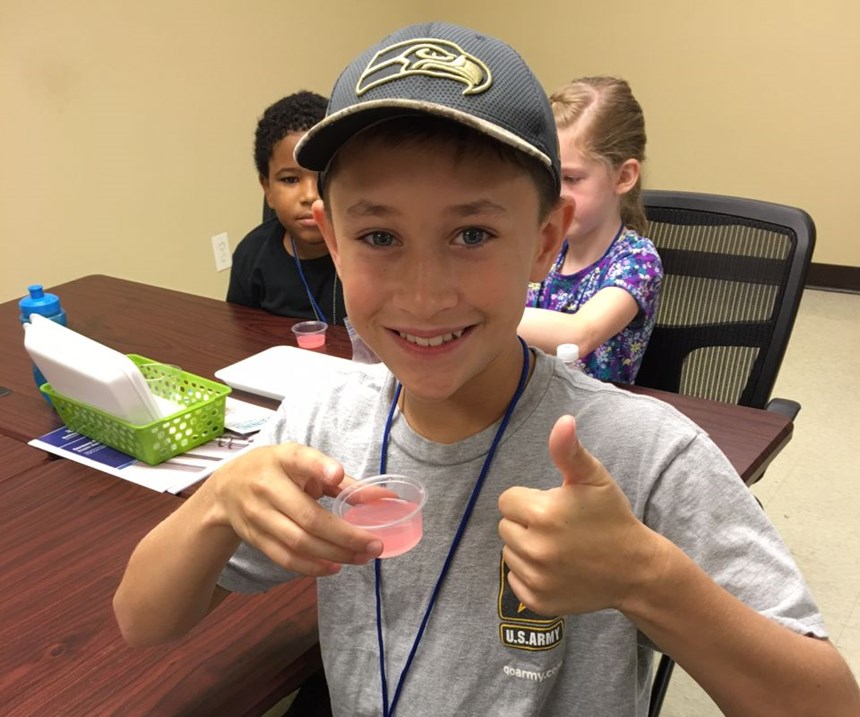

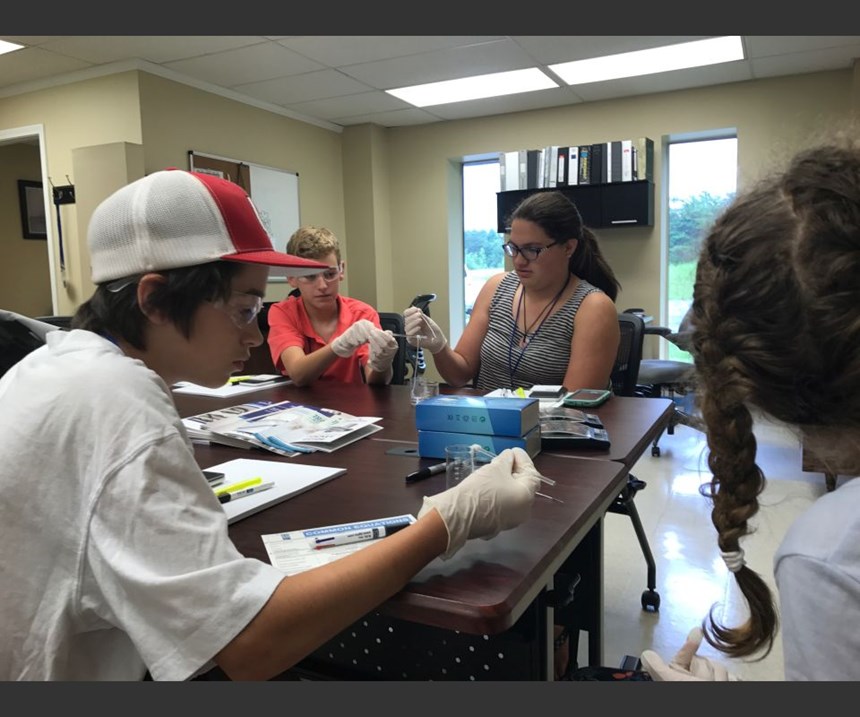

Starting kids' love of math and other STEM-related curriculum in grade school is what everyone agrees needs to happen so that they will gain an appreciation for careers in manufacturing. Mary and Marty Key are doing it.

Share

Everyone in this industry agrees that the sooner you expose kids to the idea of manufacturing as a career, the better. We all know that part of that process has to be getting kids excited about mathematics and other STEM-related curriculum while they're in middle school. Well, Mary and Marty Key are doing it by establishing a new program called Key Up Education.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreMMT Chats: The Science of Moldmaking, Part 2

In Part 2 of this two-part MMT Chat, Christina and Don continue their conversation by exploring lean manufacturing and tips on how to attract, train and retain the future workforce.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More