SLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

By all accounts K 2016 was a success. All 3,285 exhibitors were extremely pleased, according to show management, and companies reported a lot of new leads, with many closed deals over the eight days of the trade fair. A total of 230,000 attendees from more than 160 countries took part in the event. The next K show will take place October 16-23, 2019 in Düsseldorf, Germany.

According to show management, “attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. More than 70 percent of visitors stated that they received information on news and trends, 60 percent of industry decision-makers visited the show with solid investment plans and 58 percent found new suppliers. With these new purchases attendees pursued three main objectives: expand their product portfolio, extend production capacity and increase efficiency. The results of the attendee survey also confirm the positive business condition in the downstream sectors of the plastics and rubber industries: 60 percent of attendees rated current business levels as “very good” and “good” while the same percentage even expects the condition to improve over the next 12 months."

This slideshow is just a sampling of the technology highlighted at this international plastics and rubber event.

Related Content

-

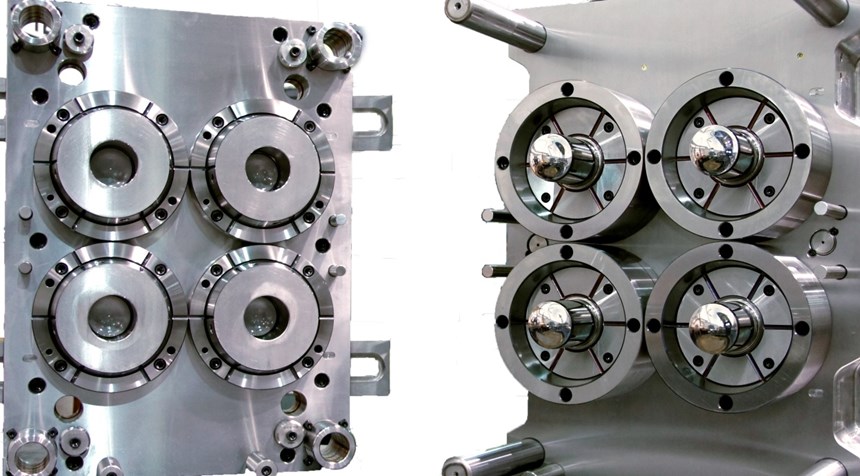

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

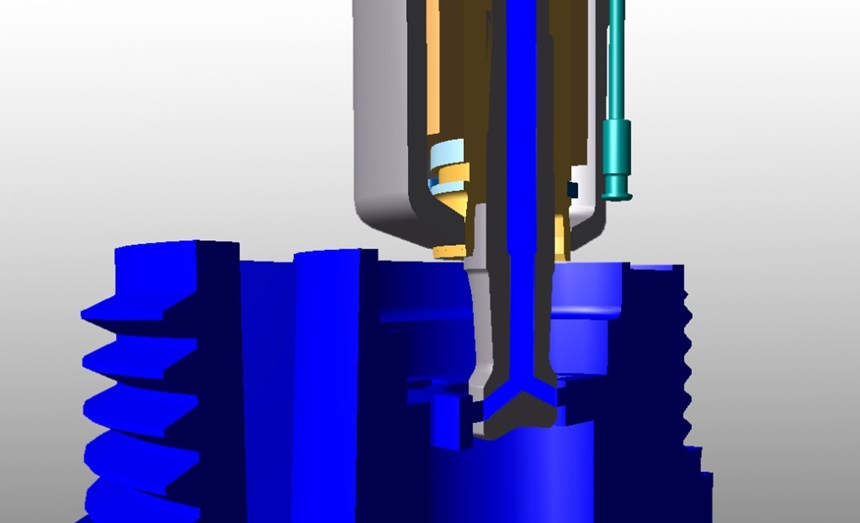

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.