Technology Tuesday: Preparing for NPE with Plastics Review

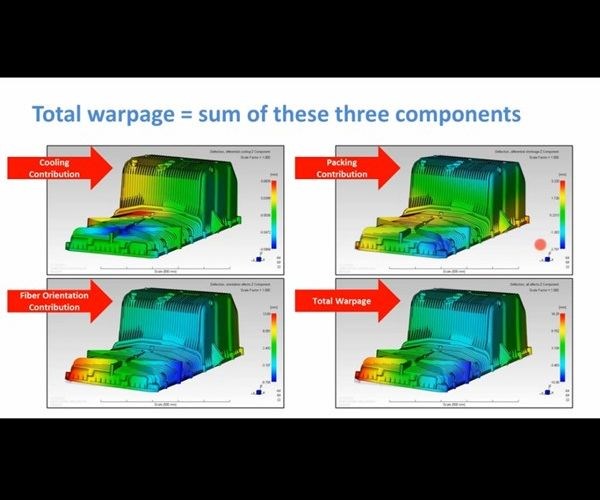

This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic.

T minus four months and 18 days till NPE2018. That’s right. With fewer than five months left till Plastics Industry Association’s big show, what better time is there to brush up on your knowledge of plastics in moldmaking? As Editorial Director Christina Fuges notes in her letter from January, 2018 is a big year. It is not too soon to start planning. This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic. Did you know that under the right treatment, recycled plastic can perform like virgin plastic? Check out the slideshow for August 2017’s TIP, in which the pros from Haidlmair and Erema weigh in on recycling. Think of the savings that using recycled plastic could bring to your wallet and to the Earth!

Need to start planning your trip to NPE2018? Be sure to check out the NPE zone, where you can find up-to-date information on show news, products and blogs, or visit the NPE event website for everything you need to plan your trip.

Featured in this week’s slideshow are articles and blogs on the latest plastics developments in moldmaking. Suppliers and consultants from RJG, Inc., Renishaw Inc., Directed Manufacturing, CAE Services Corporation, ARBURG, Inc., Erema, Haidlmair, VISI by Vero Software and Krauss-Maffei Corporation contributed to the articles and blogs in the slideshow. Links to relevant articles, blogs, series and other media are located in the slideshow captions.

Related Content

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.

-

Plastic Injection Molder Debuts EOAT, Mold Monitoring Solutions

NPE2024: Exhibiting for the first time, European-based Mouldpro ApS highlights new solutions — the Roborex and Flosense — alongside partner Globeius.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.