Multi-Process Disease In Hot Runner Molds

Multi-process disease is a complex interaction between the mold, the manifold, the material, the machine and the mold temperature controller.

Hot runner molds are great. Everyone knows that. We eliminate runners, grinding them and reprocessing them. So what's the issue? All hot runner molds are not created equal. We have all seen the application where using a hot runner mold resulted in more scrap and more regrind instead of its elimination. Why would this be? It seems really simple. You heat the channel where the plastic flows, pressurize the injection unit and the plastic flows into each cavity. So what is so complicated? Why wouldn't that just always happen in a repeatable way? Well, this plastic stuff that we push into these wonderful molds simply doesn't behave like normal material. The only thing that we use regularly that behaves a little bit like plastic is catsup. You know what happens with a new bottle of catsup. You try to make it flow—it doesn't. Then, look out—when it flows, it all comes at once! Plastic behaves the same way, but to a much greater degree.

So what does this have to do with hot runner molds? If a hot runner mold gets pressurized and flow does not start in all flow channels at the same time, something sort of bizarre happens. The plastic starts to flow in some channels and it flows very easily for awhile. As pressure builds, other cavities start to fill. Many times the ones that were originally flowing stop flowing. The ones that get filled early don't pack very well. Why is that? It is because this plastic that becomes very easy to flow while moving becomes very hard to pack once it stops flowing. Cavities filling last usually pack first.

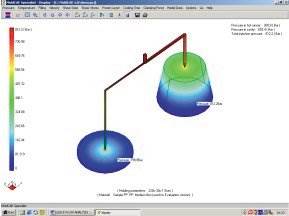

We have to step back a little bit and talk about why this happens. It is due to non-Newtonian flow. When plastic flows, the very long molecules that make up plastic align in the direction of flow. This untangles them and drops the viscosity. This allows plastic—which is relatively viscous—to flow much like water. The faster it flows the easier it goes. If a hot runner mold is designed in such a way that flow doesn't initiate in all of the channels at the same time, we have problems. Some cavities fill first and pack hard, and some cavities fill last and pack easily. Also, in a mold that is so-called balanced, where flow channels and directions are all the same from one cavity to another, there is a high possibility that the flow patterns will change over time. This is caused by the on- and-off heating of the tips, causing more or less resistance to flow in different drops over time. The end result: cavities that fill first on one shot do not fill the same on the next shot. Or in other words, the fill balance in hot runner molds tends to change from shot to shot. This is illustrated in Figure 1.

We term this phenomenon multi-process disease. All hot runner molds potentially have this problem, but to different degrees. The only sure ways to eliminate multi-process disease are to build single cavity molds or use sequential valve gating, which only allows one to flow at a time.

How to Test for Multi-Process Disease

People like hot runner molds if they behave. Behave means that the process doesn't change over time, as it does with multi-process disease. There are two easy tests to detect multi-process disease:

(1) A dynamic test where short shots (known as fill only shots) are intentionally made over a period of time, perhaps once every hour, while a mold is running. This can be done in the early stages of qualifying the tool (the earlier the better actually) so that effects can be anticipated. If the short shots are not the same every time, the fill pattern is changing.

(2) Monitor the individual cavity weights periodically—once per hour. This shows the distribution of plastic in each of the cavities. This is then plotted on a graph as shown in Figure 2. This plot also must include the average part weight (shown in red) in the middle of the pack.

What we would like to see is that the average of all cavities trends the same as each individual cavity, as is shown in Figure 2 for a cold runner mold. What this means is that all cavities' weights go up or go down in unison, indicating that there is really only one process to control here. Often, however, we see a graph that looks like Figure 3, where part weights for each cavity vary independent of one another. In this case, we have multiple processes. This four-cavity mold has four distinct processes or cavities that vary independently. Many times, as you can see, some of these cavities trend completely counter to other ones. As part weights go up in one area of the mold they go down in other areas of the mold.

A mold that does this can be highly problematic. Any mold that has multi-process disease will almost assuredly make defective parts and allow them to escape downstream to the customer. Currently, the only way to eliminate these escapes is to monitor pressure in each cavity with a cavity pressure sensor. This will detect when the pressure distribution has changed so that parts can be contained while corrective action is initiated.

Often the mold builder is the scapegoat for a multi-process disease situation. However, studies have found that it is a complex interaction between the mold, the manifold, the material, the machine, and the mold temperature controller that all contribute to the situation.

It is important that everyone involved understand this phenomenon and work together to make it manageable. There are no silver bullets and simply pointing fingers will never make the problem go away. In future articles we will discuss how each cavity of a mold can be controlled if independently actuated valve gates are installed. This is the only way to positively eliminate this problem.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Quick Flow Analysis of Hot Runners

Quick flow analysis technology can improve the selection, design and troubleshooting of hot runner tools.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)