Intelligent Equipment Solutions Alleviate Moldmaking Pain Points

Whether it’s purchase quoting, mold cleaning and tracking or intuitive process control, the following new or improved technologies could potentially keep your shop on the cutting edge.

Photo Credit (clockwise): Gunther Hot Runner Systems Inc., PCS Company, Globeius Inc. and Regal Components

As we continue to transition into 2024, keep yourself abreast of industry technology developments with this latest MoldMaking Technology roundup. The highlighted companies and pieces found below provide a brief glimpse into the intelligent products/services that are targeting mold and die applications. Editors also provide a look at software-specific products in the upcoming February 2024 issue (find all archived and recent digital issue versions here on the 1st of each new month).

Never seen some of these before? We publish new or proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar for a more streamlined approach. Follow each title link for the full product post.

Click here for our most recent cutting tools roundup.

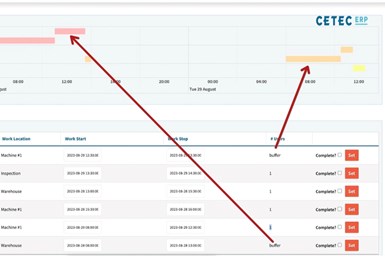

Valve Gate Sequencer Gives More Exacting Moldfilling Control

PCS Company introduces the Polimold Valve Gate Sequencer, a state-of-the-art system designed to provide injection molders with more exacting control of the moldfilling sequence during production when using valve gate hot runner systems.

According to the company, injection molds, large and small, can be more profitable by using the Polimold Valve Gate Sequencer, which enables the molding operator to control the opening and closing of the valve gate pins.

Digitized Localization Solution Precisely Pinpoints Injection Molds

Photo credit: Hasco

The Mould Track System, offered by Hasco, provides an intelligent solution with precise indoor localization to injection molding shops. As it is common for a company that has several injection molds to place some of those molds into storage after the production of a batch, knowing where exactly they are located could avoid production bottlenecks and optimize manufacturing processes.

3D Printing Tool Steels Reformulated for More Flexible, Less Brittle Filaments

Markforged’s newest versions of H13 tool steel and D2 tool steel filaments were developed to be used with its Metal X 3D fused filament fabrication (FFF) printing system and feature an updated binder that results in a significantly more flexible and less brittle filament. The additional materials are part of the company’s strategy to strengthen manufacturing resiliency by enabling industrial production at the point of need.

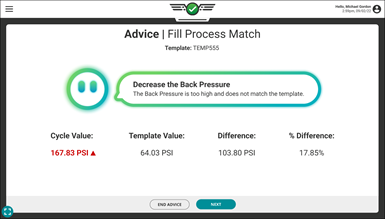

Temperature Control Unit, Hot Runner Heating Enhance Injection Molding Reliability

Günther Hot Runner Systems Inc. presents its BlueFlow hot runner heating technology, which it describes as significantly slimmer, more powerful and more energy-efficient than predecessors. The company says the BlueFlow hot runner nozzle has faster thermal reactions and is well suited for processing high-temperature resins.

Heated Nippers Enable More Efficient Degating, Plastic Part Cutting

Globeius Inc., a provider of machinery, equipment and technical support to the North and South American plastics industry, now offers heavy-duty heated nippers from MouldPro that make degating and cutting plastic parts easier and more efficient. They also help reduce hand and wrist injuries amongst operators by making the degating process less strenuous.

Intuitive Inspection Software Increases 3D Measurement Data Compatibility

With the release of its novel Zeiss Inspect 3D metrology software, Zeiss Industrial Quality Solutions offers customers numerous new functions. Zeiss Inspect Optical 3D is a solution for the inspection and evaluation of any 3D measurement data (e.g., optical 3D data, volume data, image moving data). With this release, data acquisition is accelerated, and evaluation functions are further improved. The new Autosurfacing app also automatically converts scan data into a high-precision CAD model.

Read Next

Maintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

Read MoreHow to Use and Protect Remote Machine Monitoring Data

Collecting, analyzing and securing machine data in real time can substantially improve productivity, profitability and customer satisfaction.

Read MoreProducts/Services for the Everyday Mold Builder

Happy New Year! MMT is bringing back its monthly technology/service roundups. Learn more about new and familiar companies, and the products available to the moldmaking industry.

Read More