Electronics Market Needs Complex Molds Fast

Meeting the stringent requirements in the electronic/electrical products market improves moldmaker’s overall processes.

For Wakefield, MI-based Extreme Tool and Engineering—a manufacturer of pre-production molds, Class 101 production tooling, hot runner molds, auto unscrewing molds, insert molds and manual transfer two-shot over-molds—the electronics/electrical products industry has served the nine-year old company well. Like the consumer products market, this industry also is in a constant state of change as people are always on the lookout for the latest and greatest gadgets. Extreme Tool services three distinctive areas in this large market: design and build of molds in the cellular phone market for a major global molder supplying to OEMs such as Nokia and RIM; provider of a majority of the development tooling and molding for a major OEM who builds computer periphery equipment including printers; a significant volume of insert mold tooling for automotive applications; and a great deal of work in a non-insert molded electrical application for automotive—including under the hood and the interior.

Although work in the electronics/electrical products market is primarily done overseas, Extreme Tool and Engineering President Mike Zacharias believes the work can be brought back into the U.S. “This industry needs parts faster,” Zacharias states, “and the molds need to be cheaper. However, parts are more complicated, as they often have combined parts to reduce overall cost. Tolerances are often much tighter, which in many cases is not due to end requirements but rather automation and assembly issues. This is a good market to build molds—and due to complexity and speed needs—there is room for shops in the U.S. to play.”

After opening its doors in 1998 with six people, Extreme Tool and Engineering was on the fast track to success—growing to as high as 55 people in 2005 in response to a specific job and the need to increase capacity. However, times were tough in the industry, and in 2007, Zacharias made a difficult decision to reinvent the company and had to downsize as a result. “Using a tool called Hoshin Kanri (see What Is Hoshin Kanri? sidebar)—and with the guidance of MSOE Business Excellence Consultants—we completed a short- and long-term strategic plan and made many organizational changes and employed lean initiatives, which increases our sales per man 64 percent. We just added a 10,000 square foot building to our campus and have plans for two additional remote facilities opening within the next six months. Our total square footage at this point is 22,500 feet.”

Electronics Challenges

Extreme Tool’s extra capacity makes the company well equipped to handle the challenges that come with working in the electronics/electrical products market. According to Zacharias, cosmetic requirements within telecommunications work are very stringent. “It took us several years to develop systems and processes that would enable us to meet the requirements consistently,” he elaborates. “Wall thicknesses are very thin, which causes issues of fill and ejection. We now have a much better understanding of the tooling requirements to combat, with regards to polishing, venting, ejection, etc.”

Accuracy is another issue. “The accuracy required on these molds is often at one tenth’s level in plastic, which most often means 20 percent or so of that in steel,” Zacharias explains. “On most of this tooling, it must be built to numbers and interchangeable—very little old world/fitting and traditional moldmaking occurs. Surface finish on the inside of phone molds is often much more controlled than outside surfaces on other applications (e.g. automotive). We had to develop electrode finishing techniques—including diamond polishing of electrodes and inspection—to meet cosmetic needs on the same. We also have developed detailed tool inspection plans to meet the dimensional needs of components on these tools (CMM or OGP Vision Systems).”

The Need for Speed

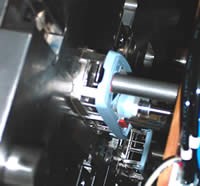

According to Zacharias, the need for speed has been the biggest hurdle the company has had to face with regard to molds in the electronics/electrical products industry. “We often build multi-cavity, Class 101 production molds with a ton of action in them in four weeks or less,” he notes. “Many of these molds have four CAM actions and six to 12 lifters per cavity. Although the parts and molds are small, they have a lot going on inside them. Further compounding the challenge, many of these programs had multiple identical and mating components that all had to be completed in same timeframe.”

Zacharias and his team tackled this challenge from several angles. “The first area we looked at is modular tooling,” he recalls. “We began to think of molds in a modular fashion versus the traditional method of everything being custom. In my opinion, this mindset is the way all or most molds will be built moving forward and is part of the natural evolution from moldmaking to mold manufacturing. As our equipment and technology has become more advanced and accurate, the art of moldmaking has been transformed to a controlled, efficient, procedure-oriented manufacturing process. It has changed our company for the better throughout. We now produce molds in half the time, hours, and cost that we did only five or so years ago.

“We also are also are privileged to work with some very good customers that have proprietary platforms/systems in place for the same as well, and I feel it is a competitive advantage for them as well as us,” Zacharias continues. “The reality of what we do is that consumers of plastic parts really don’t want to buy a mold, they want to buy plastic parts. Modular tooling systems ensure that the end customer does not buy any more than he needs to, to get the job done. This enables us and our molding customer to provide a more cost-competitive solution than what we previously would have been able to do, and as a result, we both land more business and deliver faster.”

Secondly, the company examined its scheduling and manufacturing systems. “Early on, we found out that in order to meet the needs of these customers in leadtimes needed and deliver on-time consistently, we had to manage and plan these jobs at a micro level,” Zacharias says. “We looked for off-the-shelf job shop MRP (market resource planning) systems, and struggled for several years with trying to make them work for moldmaking. In the end, we developed custom software solutions by examining all of the shortcomings of the off-the-shelf MRP systems we had tried to implement, reviewed our actual needs, and wrote integrated spreadsheets and programs that gave us the best of both worlds. I am blessed to have a ton of young, smart, engineering types working with us here at Extreme, and they are great at think outside the box type stuff like this. Our system has quoting, job planning, scheduling, costing and tracking—all integrated and highly automated. Our system is visual in nature/mostly electronic, and everyone in the company has access to it and uses it to do their job. We schedule every operation on every component, and can tell at a minute’s notice if a job is on track. This enables us to accurately forecast available capacity, give customers accurate information quickly and avoid surprises.”

The third criterion in Extreme Tool’s plan of attack was validation. “Many years ago, we determined that building a mold and throwing it over the wall was not going to cut it for these applications,” Zacharias emphasizes. “In many/most cases, we now take molds through a full validation process—including rigorous mold process development and full validation, which includes first article inspection and capability study before the molds leave our facility. We have invested heavily in training within our facility in this area, and are one of a handful of RJG Certified Mold Build and Tryout shops (see RJG Certification sidebar) in the world. Our customers now look to us to develop robust mold processes for the molds we build, before they ship, and confirm they are capable of meeting the long term needs of the program.

“We find that we can complete these tasks most often much quicker than our customers, and maintain control of the mold development timeline and result accordingly,” Zacharias adds. We also do other things like run-the-bridge/pilot production and fill the pipeline. Our customers don’t really need molds fast, they need good parts fast. We find it often makes sense for us to run the initial volumes for our customers, and then ship the mold to them for future needs. We also build many of the extras like end of arm automation and inspection fixtures along with the mold. We validate and debug them before we ship as well, and this enables our customers to receive a complete package/turnkey solution, and hit the ground running. I don’t look at these extra things as a big opportunity for revenue generation, but rather another item we add that helps make it easy to work with us and separate us from our peers. Ultimately, our end goal is no surprises, and this helps us achieve that on a routine basis. The line between moldmaker and molder is no longer a defined line—but rather a gray area—and our mission is to make it easy for them to do business with us, and take things off their plate and put it on ours.”

Impressive Results

Catering to the electronics/electrical products market successfully has benefited all areas of the shop. “Many of the systems and processes we have in place throughout our company started for the sake of serving our electronics clients’ needs,” Zacharias states. “Our guys needed to build very demanding tools, very quickly, and without these systems we never could have done it. We have GREAT customers, and I am indebted to them for having the patience they did while we learned these things with them. “We now use these same procedures and systems to meet the needs of all of our clients—in every market we serve. We plan on moving all of our molding and validation services into our newly purchased building. We feel this is our single biggest growth opportunity, as we take requirements off our customers’ list and move them onto ours. We also are building an additional toolroom within the same plant, dedicated to post sample tweaking/debugging and engineering changes and mold repairs as well. We seek relationship business and know that adding services they need is crucial to meeting this goal.”

Zacharias expects to see twofold benefits to its new plant. First, the level of service provided for validation and process development will improve with dedicated resources (i.e. man and equipment) as these guys will no longer work on anything other than these activities. Secondly, the original facility will now concentrate on only new tool builds in the most efficient manner possible. “We plan to completely reorganize our main mold building plant with a clean sheet/most efficient/lean manufacturing and flow perspective, and we expect to build molds faster and more cost effectively as a result,” Zacharias says. “We currently build molds 30 to 50 percent less expensively and two to four weeks faster than we did three to five years ago, and I have no reason to believe that similar efficiency and productivity gains won’t be required in the future. We plan to do whatever is necessary to provide our customers with the best service and most well-rounded product available at a competitive cost.”

Embracing the Market

To tap into this market, Zacharias recommends close customer communications. “Ask them what they really want,” he suggests. “Given the opportunity to do so, what could you do for them that would make them feel you had provided them with a Cadillac solution?” He also notes the importance of embracing new ways of thinking. “Forget how you used to do things and figure out how best/most efficiently to do things moving forward. You are only as good as your last job, and that last job may even be outdated now! Invest in technology and reinvent your company as often as needed. This is not comfortable but is the world we live in. Create a culture of change and hire people without bad habits who embrace change and a culture of continuous improvement. Finally, realize we live—and manufacture—in a global society. Find some way to make this a positive change on our lives rather than a negative one. Embrace it and create opportunities as a result.”

Related Content

Thriving on First-Off Molding Projects

Christina Fuges talks to Kevin Hartsoe, president of Neu Dynamics in Ivyland, Pennsylvania, about the company’s focus on the electric vehicle market, the key to its success, projects in the pipeline as well as supply chain and workforce challenges.

Read MoreMMT Chats: 5 in 5 with Neu Dynamics

MoldMaking Technology editorial director Christina Fuges chats with Kevin Hartsoe, president of Neu Dynamics to reveal their five best practices for improving efficiencies in culture, technology, process, measuring success and staying competitive ... in 5 minutes.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

Read MoreRead Next

Selective Materials Strategy Is A Potent Tool for Moldmakers

Reducing mold build costs with different steels and coatings may give North American shops more business from electronics OEMs.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More