How to Proactively Engage Educators with Plastics

RJG Inc. participates in Tuesdays for Teachers initiative to further engage educators with plastics industry career opportunities and STEM teaching resources.

In April of this year, I blogged about a third-grade teacher named Mary Key who brought her students to RJG, Inc.’s Gibsonville, North Carolina, training facility to learn about injection molding and how math and science apply to manufacturing (read the blog here). Mary’s husband, Marty, works at RJG as a trainer and consultant, and since that first “field trip,” the husband and wife have teamed up to get the word out about careers in the plastics industry by establishing Key Up for Education, an initiative that focuses on empowering grade-school students to explore the world of science, technology, engineering and mathematics (STEM) through hands-on, real-world experiences.

With the ongoing support of RJG, Inc., the Keys held two more “STEM camp” events in June, and in my blog about it, I wrote, “During the camps, the students were able to hold and look at various parts of the injection molding machine, feed plastic pellets into the hopper and watch as the machine produced parts. After camp, the parents visited the lab so that their children could show them around the machines and share with them what they learned.”

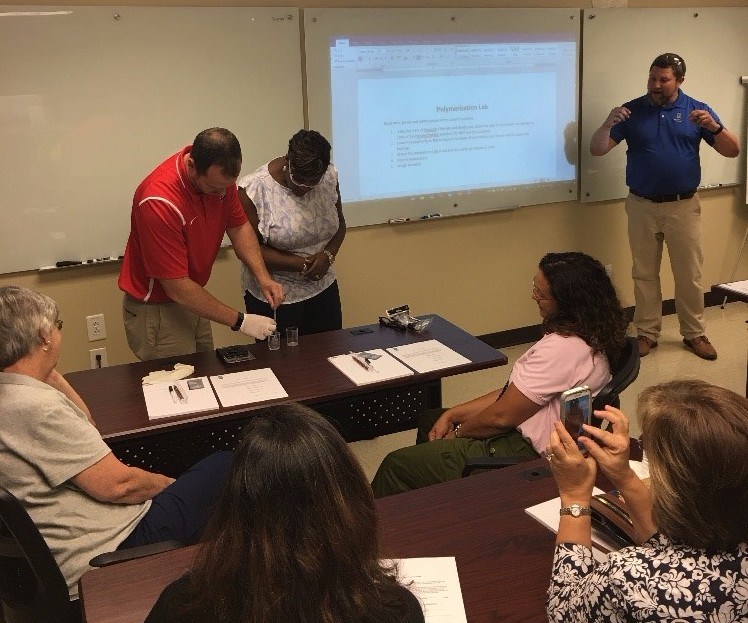

Well, the Keys and RJG recently ramped up their efforts by partnering with the Alamance County Chamber of Commerce and the Alamance County Burlington School System (in North Carolina) to host a Tuesdays for Teachers event. Tuesdays for Teachers is a program that offers local high school and middle school educators the opportunity to visit area businesses and industries. With 20 teachers in attendance, including Alamance County Career and Technical Education teachers, RJG provided a first-hand view of a Master Molder class in process. Teachers were able to see RJG’s hands-on training in person as twelve students worked to build processes on injection molding machines. They also gathered in the classroom at RJG’s facility and learned about the company’s history, products and training while participating in hands-on activities involving polymers that produce Nylon. Additionally, they learned about previous outreach efforts and how to involve and engage their own students in technical and manufacturing careers.

It’s clear that the Keys hold the key to engaging the minds of grade school, middle school and high school students, while also initiating ways to translate STEM teaching from RJG’s facility to the classroom. The programs continue to gain in popularity as the word spreads; and we’re looking forward to seeing what RJG and the Keys will do in the New Year!

By the way, I’ve been writing a lot about workforce development this year, including a feature titled Supplier-Based Training Programs Fuel Mold Industry Needs. It discusses how industry suppliers like RJG Inc. are working to ensure there are interested, enthusiastic young people learning about all aspects of our industry and the viable careers that await the right candidates.

Related Content

-

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.