AI Augments Injection Molding Process Control System

MAX, a new process advising feature added to RJG’s Copilot system, is engineered to help troubleshoot and optimize the injection molding process and addresses industry skill gap.

RJG Inc. has announced a new feature for its CoPilot process control system called MAX, the process advisor. MAX uses advanced, AI technology powered by Master Molder techniques to provide molders with real-time, expert guidance to optimize their injection molding processes, including reducing waste during production and assisting in bridging the skills gap.

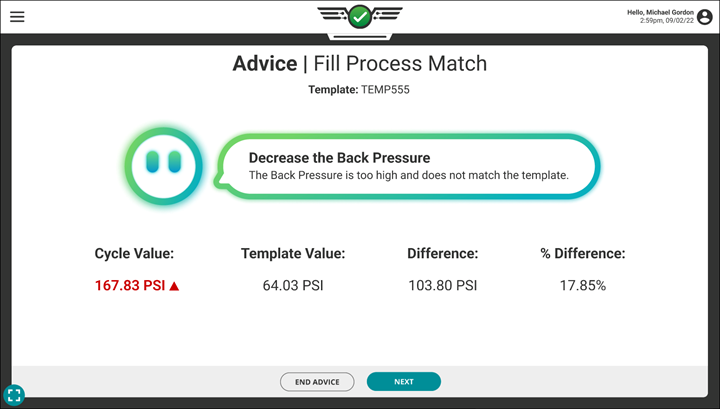

This smart assistant monitors process parameters in real time and offers troubleshooting advice to help molders rapidly resolve issues and improve productivity. RJG’s Molding Automation Xperience, or MAX for short, marks a significant enhancement to the CoPilot system, demonstrating the company’s commitment to leveraging AI to deliver molders a high level of control, efficiency and quality.

Featuring an intuitive and easy-to-use interface, MAX offers guidance to molders by delivering step-by-step instructions for restoring a process to optimal performance. This empowers personnel on the floor, regardless of their experience, to handle process issues effectively.

MAX marks an advancement in an already feature-rich CoPilot process control system. The CoPilot enables users to:

- Monitor and control injection molding processes to ensure high quality parts.

- Receive real-time, on-screen notifications when a machine is down or producing suspect parts.

- Get step-by-step advice for fixing a process.

- Set alarm limits and templates for process matching.

- View data from each shot.

- Automatically retain suspect parts and understand what happened in the process.

- Access total part and process audit records.

- Build efficiency through process automation.

For existing RJG customers looking to transition from eDart systems to CoPilot systems, RJG has launched a time-limited buy-back initiative, providing credits for its new systems. MAX is now accessible as an upgrade to the CoPilot.

Related Content

-

Process Monitoring, Cold Runner and Nozzles Bring Control, Industry 4.0 to the Mold

Ewikon touches on a few of its popular innovations previously highlighted at K 2019, including the HPS III-MV multi-tip nozzle, smart Control and Coolshot.

-

How to Implement a Remote Validation Process

A review of the setup and use of a remote mold validation kit.

-

An Integrated Desktop Approach to Mold Production

Versatile, scalable, additive machining and molding systems optimize moldmaking operations and support training initiatives.