Redefining Learning Labs

Training facility partners with a local North Carolina community college to challenge advanced manufacturing students to design parts, which will then be converted into mold designs for the training facility.

RJG strives to educate as many students as possible. They recently saw an opportunity to fulfill one of their own needs while also providing a learning opportunity to students at Forsyth Technical Community College (FTCC) in Winston Salem, NC.

Here, RJG Consultant and Trainer Marty Key shares the details:

RJG recently received eight rapid unit inserts from our lab partner Progressive Components, which meant we had to come up with some part ideas for which we’d produce molds. However, instead of our team developing the concepts, we thought this would be a fun learning experience for students interested in manufacturing.

So, we decided to pass this challenge onto the Advanced Manufacturing students at FTCC, which recently opened its Center for Advanced Manufacturing education facility, a 30,000 square foot building with two CAD and drafting labs, a 3D printing lab housing seven 3D printers, a 25-bay welding lab, and a computer integrated machining lab. This set up along with the center’s capabilities and course offerings made FTCC a great partner in this part design/mold design project.

This center provides the perfect environment for students to learn with real-world manufacturing methods, such as advanced 5S organizational skills. FTCC has worked hard to establish itself as a great resource and partner with local businesses. Their programs address the needs of various companies, like Deere Hitachi and Siemens. The students are exposed to a wide variety of different manufacturing methods, creating well-rounded employees for the future.

After touring the facility and discussing the proposed part design project, we presented the challenge to the students. They accepted the challenge. We then did a presentation on injection molding with an overview of injection molding equipment, process and performance. We also addressed generic rules for plastic part and mold design, which we believed the students would find helpful when creating their part designs.

We decided to make the project as real world as possible, so we established a three-week deadline for design completion. We gave students design parameters to follow and requested that they treat us as a customer. We stressed the importance of understanding that they will not always have the answer, and the value of building the relationship with the customer and coworkers to resolve issues.

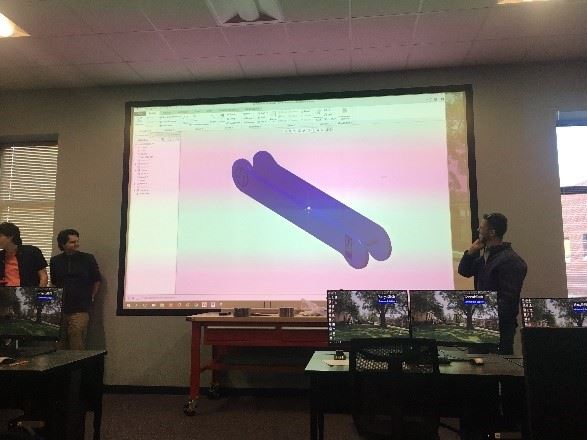

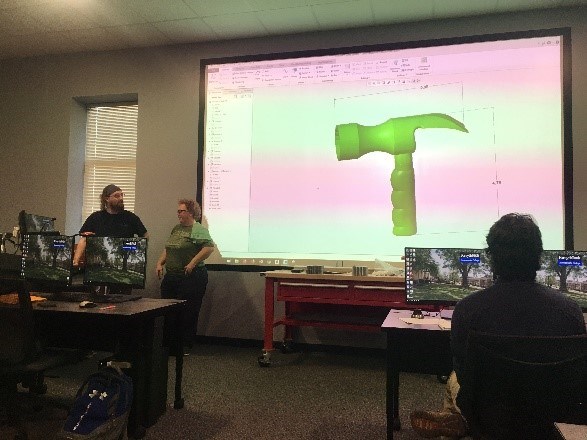

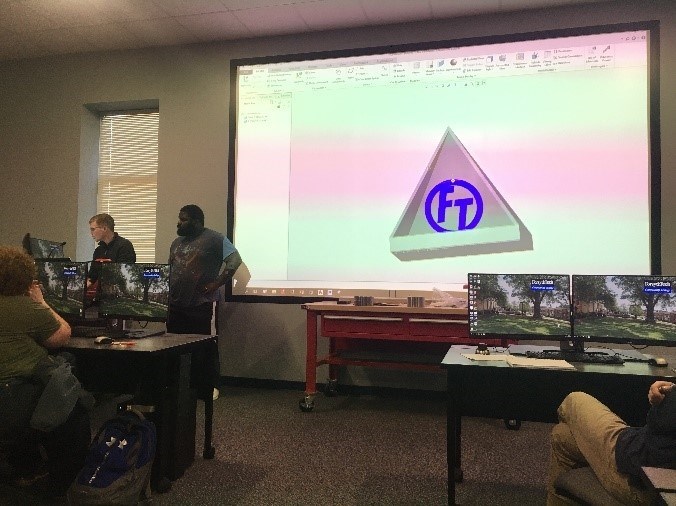

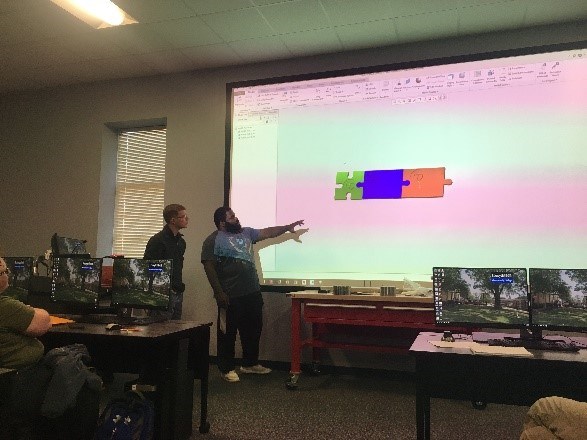

We waited the three weeks and fielded a few questions along the way. At the deadline, we returned to FTCC to discover that the students divided into three groups to create four different designs. See slideshow.

We were astonished by the creativity, effort, and professionalism the students exhibited while working through the project. During each presentation, the students also talked through their constraints and solutions. The presentations and discussions spoke to how the program was also preparing students for future manufacturing careers, not just jobs. It was clear that they were already functioning and thinking at a high level in the manufacturing world. The students, the department, and FTCC more than exceeded our expectations.

The next step is to convert the part designs into mold designs. Once that process is complete, we will begin reaching out to mold builders who are willing to partner with us to create molds for use in our labs. We will showcase the parts with the logos of FTCC, RJG®, and the mold builder as a way to promote the partnership.

If interested, click here.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreMMT Chats: It’s Time to Play … The Moldmaker Card Game! Yes, a Game to Educate and Entertain

MoldMaking Technology Editorial Director Christina Fuges connects with Professor Steffen Ritter from Reutlingen University in Germany about the card game for moldmakers he developed to help promote and educate our next generation of moldmaking professionals in a fun way. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More