Tech Trends: All the Small Things

These products from RJG, Tungaloy, Rhino Products, LLC, Walter and Gesswein are designed to fit within moldmaking processes.

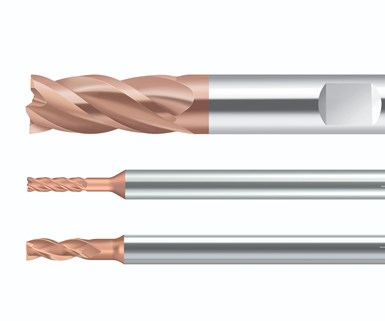

There are a lot of small parts working together in moldmaking that help make a mold, whether it be simple or complex, successful. Below, you can find products from MoldMaking Technology supplier companies that help along in the moldmaking process. There are cavity pressure sensors ideal for use with tightly packed ejector pins, cutting tools useful for meeting threading applications or with a wide variety of cutting depths, 3D printers that use the latest in digital light processing technology or even support pads to keep items safely lifted within your shop. Check out the brief description of each product below, or click on the product link to see more details.

Interested in More?

Keep in the know about recent mold manufacturing updates with a review of recent products and services announcements from MoldMaking Technology’s comprehensive list of supplier companies.

Browse our entire database of moldmaking products in the products section. You can browse to stay updated on the latest product offerings, or search for specific product information based on categories.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More