Online, Self-Paced Injection Molding Training Course Bridges the Skills Gap

RJG releases the “Essentials of Injection Molding” eLearning course. Portioned out into digestible segments, it can help new hires efficiently familiarize with industry terms and foundational concepts.

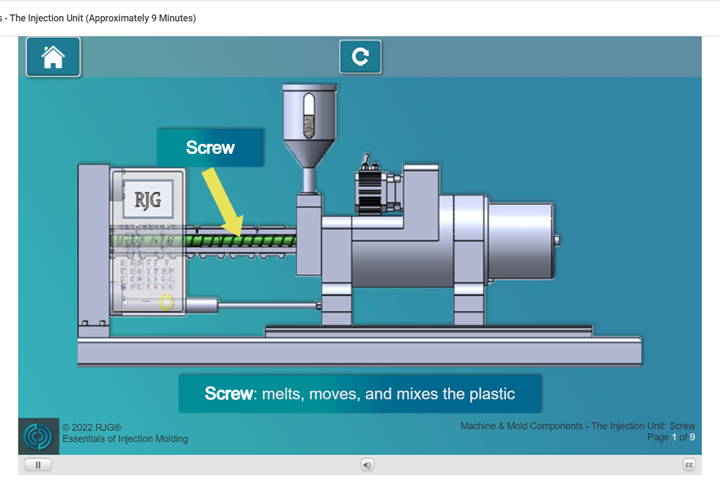

Photo Credit: RJG Inc.

RJG Inc. announces the release of its new online “Essentials of Injection Molding” eLearning course. It replaces the in-person “Injection Molding Essentials” course and is available as of February 2022.

“Essentials of Injection Molding” is an introductory course in the RJG Training Academy and is offered online in an interactive, self-paced platform. The online platform enables students to benefit from RJG’s training without travel costs or the need to spend time away from work. Interactive activities and problem-solving utilizes various learning styles in order to ensure maximum knowledge retention and provide tools that can immediately be put to use.

Newcomers, as well as those who are looking for a refresher, will come away from this course with a common foundation from which to advance their knowledge and skills in injection molding, RJG says. Learners will have an introduction to the four plastic variables, along with an orientation to the phases involved in Decoupled Molding.

The objectives of the course include:

- Identify machine and mold components and their primary functions

- Classify properties and characteristics of thermoplastic materials

- Examine the four plastic variables:

- How they are influenced by primary machine settings during a Decoupled Molding II process

- Their relationship to common defects

- Recognize common safety hazards, symbols and functions of safety mechanisms

- Outline the keys to profitable molding

In order to receive the most benefit possible and gain the necessary tools to succeed in more advanced courses, RJG says “Essentials of Injection Molding” eLearning can be bundled with the “Math for Molders” eLearning course at a discounted rate. The eLearning Essentials Bundle will be available at the same time as “Essentials of Injection Molding.”

Related Content

-

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

-

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

-

Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.