Study Shows Advantages of Mold Heating and Cooling Technologies

RocTool, a developer of mold heating and cooling technologies, shares the findings of a study it conducted to identify a range of resin materials that successfully use RocTool’s molding technologies to produce high-quality parts with high flow and reduced cavity pressure.

RocTool worked in conjunction with RJG Inc. a leader in injection molding training, technology, and resources, to demonstrate the advantages of RocTool’s technologies including flow improvement, reduced cavity pressure, high surface replication of the mold, and significant gloss improvement.

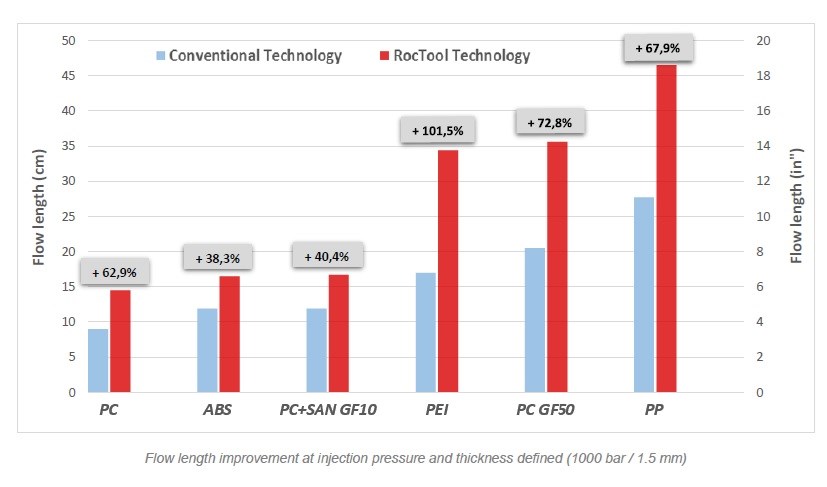

One of the main challenges in the plastics industry is reducing overall part thickness. The flow increase with RocTool induction heating technology delivers design opportunities and pushes the limits in creating thin-wall applications.

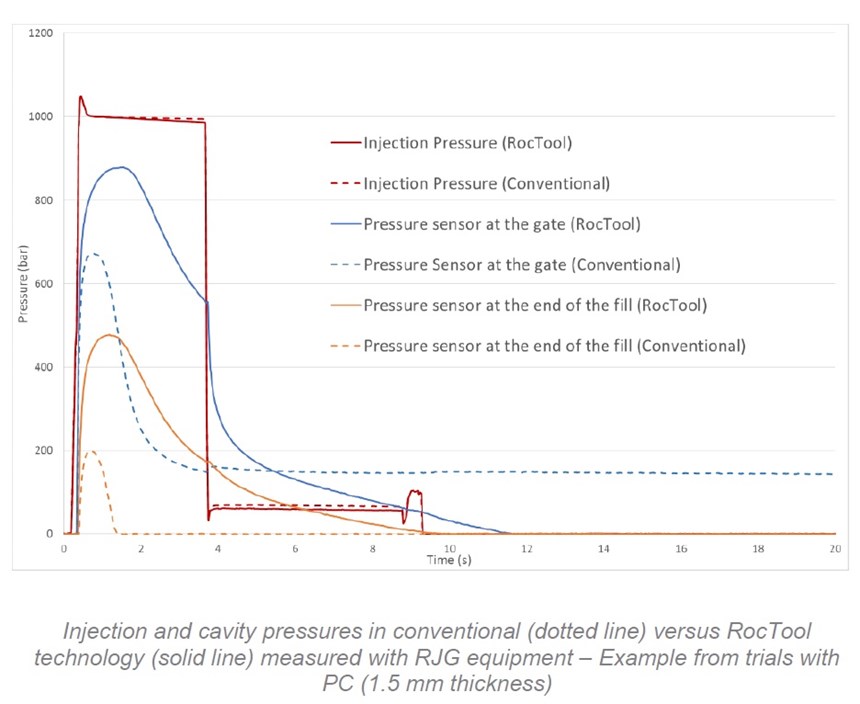

RocTool developed a specific spiral mold to calculate the flow length while pressure sensors were implemented by RJG Inc. to assess the capability of RocTool technology to improve mold filling and reduce the drop of pressure. The spiral mold was developed with variable thickness (from 0.5 mm to 1.5 mm) allowing a complete material characterization. RJG’s process monitoring “eDART System™” collected the data from the sensors which were implemented behind the ejector pin and located close to the gate and at the end of the fill.

“The partnership project provided added value in our ongoing characterization of resins for the HD Plastics™ material database,” says Mathieu Boulanger, RocTool CEO. The company is evaluating a range of resins from various material suppliers. RocTool is now capable of demonstrating the additional benefits of its technology beyond just a cosmetic advantage. RocTool can provide true comparison data for parts produced with RocTool technologies versus those made via conventional injection molding. “This information can be very useful and will provide designers with expanded options,” says Boulanger. “We can now bring this unique data directly to the OEM.”

As presented on the pressure graph, the drop of pressure is radically reduced between the injection machine pressure imposed (1000 bar) and the cavity pressure measured with RJG sensors. The pressure measured with the RJG sensors shows a reduction of the pressure drop from the injection machine with RocTool technology. It is clearly observed on the pressure sensor at the gate (blue lines), the delta between the RocTool and conventional curves is 210 bar. This is emphasized with the second sensor at the end of the fill. That reflects an optimization of the pressure drop using RocTool technology which allows the reducing of thickness and sometimes the number of gates.

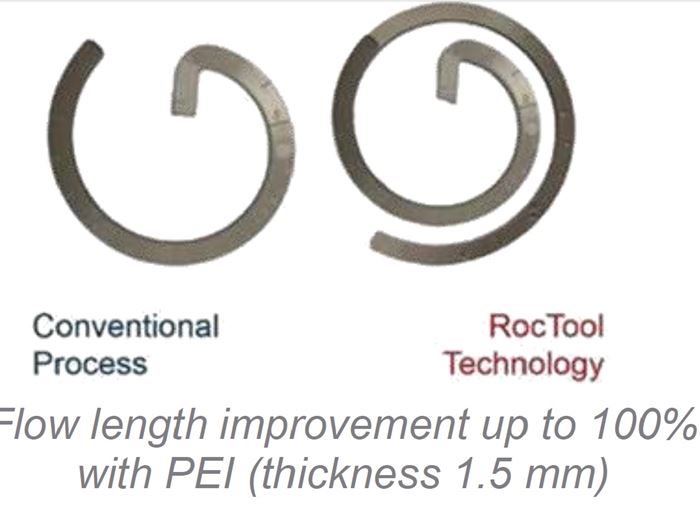

This first study includes six resins covering commodity, premium, and performance categories. Depending on the material, the evaluation revealed that RocTool’s molding technologies can double the flow length. In addition, the level of mold surface replication climbed to 97.2%, thus providing product designers with a premium look, high gloss, and a matching texture versus traditional molding. The gloss improvement is of particular note with fiber content resins.

The gloss for TPO was measured at 41 GU in a conventional process compared to 79 GU with RocTool technology. Moreover, strong results were seen with filled materials such as 10% glass-filled PC-SAN which had a 130% improvement.

RocTool has now characterized many materials for inclusion in its HD Plastics™ material database. The company will continue to broaden its material database, evaluating not only targeted commodity resins but also high-performance resins and ultra-polymers. The database will be available on the HD Plastics™ website by Q3 2017.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More