5 Questions to Ask Before Instrumenting a Mold

Instrumenting an injection molding machine with sensors can be a daunting task. It is a huge investment, after all, so how do you ensure that it will pay off in the end? The key is knowing the right questions to ask before you even begin. Here are the 5 most important questions to ask in chronological order.

Sensors and molds

Five questions to answer before you instrument a mold:

1. What do you want the sensor to do for you?

This is the most critical question to ask yourself before installing sensors in your mold. But most people stall right here because they’re not sure what functions a sensor can perform. A lot of people just want to instrument a tool because they’ve heard they should run DECOUPLED MOLDING® processes, or they want to try out process control software. Others are curious about the ability to collect data, track a part to a molding cycle, resolve ongoing challenges, or create a template to maintain or transfer processes. Whatever the answer, this single question needs one before proceeding so you can make decisions to work toward your goal moving forward.

Once you answer that question, you can begin to explore the many different functions sensors can serve if used correctly. Some examples are: monitoring pressure at a specific area in the cavity, transferring the injection portion of the cycle to hold via pressure or temperature, detecting mold defection, sequencing valves gates, sorting, and the list goes on. Once you know what you want the sensor to achieve, you have some important decisions to make.

2. Where do you want to install the sensor?

Now to install it. Conventional installation techniques to consider include post gate, mid-cavity, and end of fill, but there are more less common locations in addition to these. You may need one or a combination of these techniques, depending on your particular project. In some cases, it’s not necessary to sensor every cavity.

3. What Type of Sensor Technology Do You Need?

Once you determine what you want to achieve and where you need to place your sensors, then the next step is to determine what type of sensor technology to use. There are several factors to take into consideration, including available real-estate in the tool and cost. The two pressure sensor options we offer are Strain Gage and Piezoelectric. Strain Gage sensors generally are more cost-effective, require less maintenance, and have less noise but require more space.

4. How Should You Install the Sensor?

The most common installation styles for pressure sensors are direct and in-direct. Direct is when the sensor comes in contact with the plastic, sometimes called flush mount. In-direct is when the sensor is mounted away from the area of interest, and the pressure is transferred to the sensor via transfer pin, static pin, or ejector sleeve.

After decades of sensor installs, customer feedback, and testing, we firmly believe that mounting the sensor in the clamping plate and utilizing a transfer pin to transfer the pressure is the most robust configuration. Some of the benefits include:

- Mitigating the chances of damaging the sensor due to the tool’s action or while it is serviced on the bench

- Ease of accessibility

- Minimizing heat exposer to the sensor

- Improving the sensor’s life by removing it from the movement and shock of the ejector plate

5. What Load Capacity Do You Need?

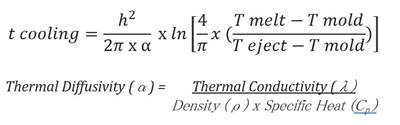

Next, we move towards determining the load capacity of the sensor. The load capacity is determined by the predicted force that will be exerted on the sensor. You can make this determination in several ways, the preferred method being a flow simulation with predictions of the pressure in your chosen area. If this is not available, you can resort to the material datasheet, which frequently gives a pressure or tonnage factor. This gives you the recommended pressure per square inch required within the cavity to mold that particular resin properly.

If the tool under consideration for sensoring is already built and simulations are not a luxury you have, you can perform a Short Shot Study. To do this, you fill the part gradually at your preferred linear speed or volumetric flow rate and observe the filling pattern. Determining Post Gate (PG) is fairly straight forward, however determining Mid-Cavity and End of Fill (EOF) can be a little trickier depending on the material, flow rate, and geometry. The key is to not make too many assumptions without supporting your decisions with actual data.

The Key Takeaway

Putting a sensor anywhere in a tool can give you some form of data, but it may not be value-added. The key is knowing upfront what you want the sensor to do for you.

Related Content

MMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreRead Next

Injection Molding Simulation Prediction vs. Actual

Simulations have come a long way in the last three decades, but if we seek to prevent dimensional variation, we must understand what provides the highest level of accuracy so we can make good injection mold engineering decisions.

Read MoreThe Effect of Pressure and Temperature on Part Quality and Dimensions

Injection molding is a complex system of machinery, fluid dynamics, and thermal conductivity. And that’s just the tip of the iceberg. Let’s simplify it. Let’s break the mold down into two simple parts, the heat exchanger and the pressure vessel, and review how they can impact overall part quality and dimensions.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More