DME Company

29111 Stephenson Hwy.

Madison Heights, MI 48071 US

800-626-6653 | 248-398-6000

dme@dme.net

dme.net

About DME Company

DME is committed to earning your business everyday by bringing you new, innovative and cost-effective products and services. Time earned knowledge, molding industry expertise and cutting-edge technology makes us the company to partner with for your next project. Our goal is your success.

IS THIS YOUR COMPANY?

Video Gallery

DME DURA Collapsible Cores Key Features

DME DURA Core Collapsible Cores Introducing DURA CORE, an innovative collapsible core solution: a groundbreaking ...

DURA Collapsible Cores Overview

DME DURA Core Collapsible Cores The Next-Gen Collapsible Core. Introducing DURA CORE, an innovative collapsible core ...

EcoONE DME Final 2024 06 19 V1 1

StellarONE Hot Runner Systems Final V1 2024 04 04

As Seen On MoldMaking Technology

DME Company Supplies the Following Products

- Air and Hydraulic Cylinders

- Air Grinders

- Aluminum Alloys

- Blades

- Bushings

- Chillers

- Cleaners

- Cooling Systems

- Core Pins

- Counters

- Cutting Fluids

- Cutting Tools

- Date Inserts

- Die Cast Dies

- Ejector Pins, or "Knock-out Pins"

- End Mills

- Fixtures

- Gages

- Grinding Wheels

- Heat Transfer Fluids

- Heating Equipment

- Hot Halves

- Hot Runner Manifolds

- Hydraulic Valve Gate Nozzles

- Injection Molds

- Inserts

- Interlocks, or Taperlocks

- Internal Mold Cooling Products

- Leader Pins

- Lifters

- Locating Rings

- Machining Services

- Manual Cleaning Equipment

- Mold Bases and Frames

- Mold Cleaning Services

- Mold Design Services

- Mold Finishing Systems

- Mold Flow and Simulation Services

- Mold Insulation

- Mold Maintenance & Repair Services

- Mold Sprays, Grease, Lubricants & Releases

- Mold Wiring

- Mounted Points

- O-rings

- Part & Tooling Production Services—Additive Manufacturing

- Pneumatic Valve Gate Nozzles

- Polishing Equipment

- Power and Thermocouple Cables

- Precision Hand Tools

- Pressure Controls, Sensors, Monitors

- Process Controllers

- Pry Bars

- Quick Mold Change Systems

- Reamers

- Replacement Parts

- Rust Preventatives

- Safety Equipment

- Scrapers

- Setup Cart

- Slides

- Socket Head Cap

- Sprue Bushings

- Stainless Steel

- Stop Pins

- Storage Equipment/Services

- Straight Locks

- Support Pillars

- Switches or Indicators

- Temperature Controls, Monitors, Sensors

- Thermal Hot Tip Nozzles

- Thermal Pin/Heat Pipes

- Tool Steel/Mold Steel

- Toolholders

- Trimmers

- Ultrasonic Cleaning Equipment

- Valve Gate Controllers

- Valve Gate Sequencers

- Wear Plates

Editorial, News, and Products

-

Expanded Hot Runner System Increases Manifold Sizes; Single Nozzle

DME Company highlights its EcoOne hot runner system, a configurable manifold and component system for time and cost-sensitive commodity applications, that has been expanded to include a single drop nozzle (hot sprue bushing), a 16-drop system and larger manifolds (600mm × 600mm) to complement the initially released one, two, four and eight-drop system family.

-

The Year in Webinars: Top Moldmaking Insights From 2024

Dive back into the year’s most popular webinars that delivered actionable strategies, emerging trends, and expert knowledge to the moldmaking community.

-

2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

-

Recent Innovations in Mold Components and Hot Runners

In this most recent product roundup, MMT continues to offer a variety of innovative as well as tried-and-true technologies to benefit moldmakers.

-

Video: Mold Component Technology Solutions Boost Sustainability

Sustainable, productivity-boosting innovations for moldmakers, including stress relief, traceability and cooling solutions.

-

SPE MTD Opens Nominations for 2025 Moldmaking Distinction Awards

The Mold Technologies Division of the Society of Plastics Engineers, Inc. is seeking nominees for its international Mold Maker, Mold Designer, Mold Repair Tech and Apprentice of the Year awards.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

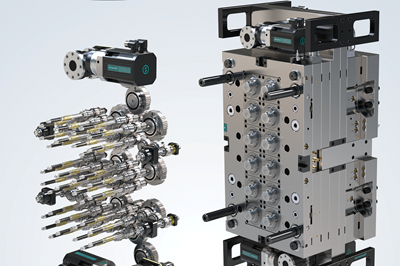

Servo Unscrewing Device Delivers High Performance to Multi-Cavity Molds

NPE2024: Electric Servomold systems by DME answer the demands made on high-performance injection molds, enabling precise, more environmentally friendly process reliability.

-

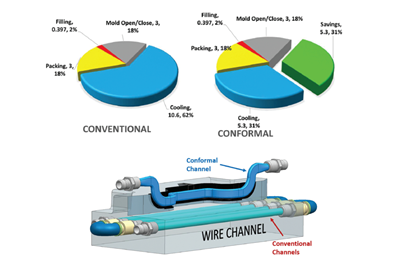

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

VIDEO: Why Is Sustainability Important to Mold Builders

Marta Orozco with DME shares ways mold builders can be a part of building a more sustainable future.

-

Moldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

-

Hot Runner Tips, Apprenticeships & Waterline Maintenance, Oh My! MMT's June Top Hits

Take a look at MMT’s top hits from June based on Google Analytics.

-

VIDEO: Full, Automatic Waterline Maintenance

Tyler Boss and Scott Smith of DME Company review the key components of comprehensive waterline channel maintenance.

-

Compact, Robust and Customizable Hydraulic Cylinders

DME exclusively distributes AHP Merkle cylinders, designed and developed to meet the needs of moldmakers for the plastic injection and die-casting industries.

-

PTXPO 2023 Preview: Advancing the Mold With Featured Mold Component, Hot Runner Technology

There’s no doubt mold components and hot runners are important parts of the moldmaking industry. This preview gives mold buyers, mold builders and injection molders a look into PTXPO exhibitors displaying these technologies at the show.

-

Unscrewing Devices, Hot Runner Systems Advance the Mold

Tooling technology company DME highlights its servomold unscrewing devices and smartONE systems at PTXPO to ensure parts perform in fit, form and function.

-

PTXPO Preview 2023: 3D Printing, Machining and Cutting Tools Technology and Services

The Moldmaking Pavilion powered by Amerimold is one of seven pavilions returning to PTXPO. Take a moment to familiarize yourself with those exhibitors that can fulfill your 3D printing and machining needs.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Technology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

-

Thermal Management, Modular Mold Systems, IoT Connectivity Demonstrated at K Show

Three new platforms displayed by DME target reduced energy consumption, costs through boosted productivity and are more sustainable for part and mold designers, molder and toolmakers.

-

From Injection Mold Venting to Runnerless Micro Molds: MMT's Top-Viewed June Content

The MoldMaking Technology team has compiled a list of the top-viewed June content based on analytics. This month, we covered an array of topics including injection mold venting, business strategies and runnerless micro molds. Take a look at what you might have missed!

-

VIDEO:"The Smith Boys" on How Moldmaking is an Innovation Machine

"The Smith Boys" AKA President of DME Peter Smith and Director of Sales, Scott Smith discuss why the moldmaking industry is an innovation machine and how it is crucial to remedying global supply chain issues.

-

Hot Runner Temperature Controller Displays Intuitive Operator Interface

DME’s MPC family of hot runner control systems brings advanced and exclusive features to decrease setup time and simplified control, including an integrated troubleshooting and service guide.

-

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

-

SPE Mold Technologies Division Seeks Nominations for Mold Maker, Mold Designer of the Year Award 2022

For consideration, nominees should demonstrate strong technical expertise, a reputation for conducting fair, honest business and have made contributions to SPE and/or industry. Deadline to submit is Feb. 15, 2022.

-

Amerimold 2021 Post-Show Flashback: Build

MMT looks back on the return of an in-person Amerimold in September after a year-long pandemic.

-

Collapsible Cores Optimize Molding Threads and Undercuts

DME’s S-Core Collapsible Cores enable parts production from six to 400 mm and three different segment designs.

-

DME Brings EZ Latch Locks, Servomold and S-Core to Amerimold

DME’s EZ latch locks, Servomold unscrewing devices and new S-Core collapsible cores offer multiple configurations and promise longevity, flexibility and ease of use for moldmakers.

-

External Latch Lock Reliably Controls Mold Plate Sequencing

The DME EZ-LATCH patent-pending lock design provides a long-lasting, more reliable easy-to-install lock for plate sequencing.

-

Side Lock Alignment Delivers More Precise Alignment and Holding Power

The DME LT-Series LifeTime Roller Lock offers an improved design and three advanced materials to address the need for improved mold alignment in high-precision molding applications.

-

Mold Lifter Self-Adjustment System Compensates for Misalignment

DME Accualign Lifter features a multi-axis self-adjustment system to avoid misalignment, reducing costly, unplanned molding process mishaps.

-

High-Performance Unscrewing Device for Multi-Cavity Molds

DME’s servo unscrewing device for injection molds, has the ability to rotate the core itself 180º for 2 shot applications, unscrew then eject after the second shot.

-

Mold Inserts Ensure Versatile Traceability Solutions

DME is providing customers with mold inserts for date, part and resin identification.

-

2020 Sourcing & Technology Guide: Inspection/Measurement

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Inspection/Measurement.

-

Valve Gate Hot Runner System Provides Common Design Platform

DME’s Smart One valve gate hot runner system provides a common design platform.

-

eStore Offers Large Portfolio of Products

DME offers a large portfolio of products, all available with rapid delivery. The company’s eSTORE offers a 24/7 one-stop-shop to thousands of products and tens of thousands of products with real-time order processing and status updates.

-

Mold Builder Just Figures It Out: From Face Shield Mold Design to Sales on a Site in 6 Days!

Within three days, Bryne Tool + Design of Rockford, Michigan, sold 4,000 face shields at $2.95 each (and available in 10 packs) from a mold that ownership donated.

-

COVID-19 Is a Rallying Call to the Plastics Industry to Redesign, Refocus and Reshore

Mold manufacturers who have been critiqued for slow lead times, as compared to the overseas competition, are proving to themselves and customers during COVID-19 that North American mold manufacturers and suppliers can unite and do things at an extraordinary speed.

-

PODCAST: The Thinker, The Problem-Solver and The Happiness Maker Talk AM

On this episode of The Manufacturing Alliance Podcast, we interview Milacron DME, Forecast 3D and Carbon about finding the right applications for AM, investigating new opportunities and securing influential relationships to grow with additive.

-

PODCAST: Additive Panel Speaks Out about Technology Expansion

On this episode of The Manufacturing Alliance Podcast, MoldMaking Technology’s Christina Fuges sits down with Tony Demakis to interview three leading additive manufacturing and 3D printing technology suppliers.

-

K Show Report: Next-Level Efficiency and Control

With a show as big as K 2019 with more than 3,000 exhibitors from 63 nations, you may think that identifying a theme among all the technology would be difficult, but after all is said and done, two words come to mind: efficiency and control.

-

Getting Hot and Heavy during a Little Hot Runner Training

If a mold is the heart of a molding system, then the hot runner system is the heart of a hot runner mold, and I recently learned that there is a lot to know when it comes to designing and maintaining these systems to ensure optimal mold and part quality and performance.

-

MoldTrax Hot Runner Extravaganza Delivers on Expertise and Education

The “Who’s Who” in processing and hot runner technologies turned out to educate attendees with well-honed wisdom and experience.

-

DME Reconnects with North American Moldmaking Industry

MMT sat down with DME Company President Peter R. Smith to learn how the company has refocused its goals and objectives for serving the moldmaking industry.

-

2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

-

2018 Technology Review and Sourcing Guide: Hot Runners

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including hot runners.

-

2018 Technology Review and Sourcing Guide: Mold Maintenance, Repair & Surface Treatment

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold maintenance, repair & surface treatment.

-

2018 Technology Review and Sourcing Guide: Mold Components

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold components.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

-

Standardization Solutions Drive Mold Component Innovations

Mold component suppliers continue to standardize products that speed mold building while also developing technology that addresses design, cooling, release and other challenges.

-

Technology Tuesday: Hot-Runner Maintenance

Cruise through this week’s Technology Tuesday slideshow to see articles and products on hot-runner maintenance.

-

Statistics Uphold Mexico’s Importance in Plastics Industry

Did you know that Mexico is the world’s second largest importer of molds and tools?

-

Mexico: Manufacturing Mecca to the South

A mold-building perspective on Mexico’s manufacturing opportunities, trends and challenges.

-

Amerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

-

SLIDESHOW: The Final Countdown to Amerimold

It’s Amerimold Eve! Our exhibitors are assembling and putting final touches on their booth displays today and there are so many new companies – plus familiar companies who have something new to show attendees. Amerimold 2017 is not to be missed.

-

Technology Tuesday: Hot Runners and Mold Components

This week’s Tech Tuesday blog brings readers a review of several products announced during the last few weeks, namely hot runner and mold componentry.

-

Milacron's DME Announces Partnership with Linear AMS for Conformal Cooling Solution

Milacron’s DME Product Brand Announces Partnership with 3D Additive Leader Linear AMS to Provide Revolutionary Conformal Cooling Solutions under its New TruCool® Product Line

-

Technology Showcase: Case Studies, Part 2

For the many differences between moldmaking companies that I’ve observed, there are just as many similarities, and by that I mean challenges shared. You may find some solutions here.

-

Throwback Thursday: Best Practices for Surface Finishing

Surface finishing is as critical an aspect of building a mold as the design, so a review of some best practices is always a good idea.

-

Quickly Getting to the Root of the Problem

Diagnostic device helps molders simply check hot runner cables to ensure connectivity.

-

Mold Maker, Designer Recognized at Amerimold

SPE presented its moldmaker and mold designer of the year awards to Harry Raimondi of Bales Metal Surface Solutions (Downer’s Grove, Illinois) and Chris Hanes of Micro Mold Company Inc. and Plastikos Inc. (Erie, Pennsylvania).

-

Common Sense Innovation and Moldmaker Collaboration

As I walked the aisles of NPE last month, taking in all the plastics-related technologies and solutions on display, two obvious trends emerged: logical innovation and moldmaker collaboration.

-

Hot Runner Running Efficiently?

Follow these tips to set up your system and keep it running smoothly.

-

A Handy Reference

Whether the goal is to learn or to refresh existing knowledge, this online tool delivers with diagrams and animations that illustrate concepts at the heart of any mold manufacturing operation.

-

NAFTA Region Market Opportunities for Mold Manufacturers

Are you interested in learning more about trade policy updates, top export growth markets, exporting basics, developing an exporting strategy and the costs associated with exporting? Then join us for the first in a four-part educational webinar series on international affairs and trade education tomorrow, March 26th, 2 p.m. EST.

-

Moldmaking Opportunities in NAFTA Markets

North America contains the two largest trading partners for the U.S. plastics industry—Mexico and Canada. In 2012, these two countries were the destination for $13.6 billion and $12.5 billion worth of U.S. plastics industry exports, respectively. Combined, this represented 31 percent of total U.S. plastics industry exports in 2012.

-

For Better Mold Venting, Start with the Metal

Selecting the right material for specific mold components can help prevent a number of costly issues.

-

Standardizing Short- and Long-Run Production

New hot sprue bushing technology makes it possible to replicate the full hot runner system for low-volume production.

-

Mold Designer and Moldmaker of the Year Awards at NPE2012

The Society of Plastic Engineers/Mold Making and Mold Design Division honored two of its members during the Division’s Annual Business Meeting at ANTEC 2012, which was held in conjunction with NPE2012. 2012 Mold Designer of the Year: Barbara Arnold – Feret from Fort Worth, TX.

-

Simplify and Streamline

Technology suppliers discuss how equipment speeds time-to-market.

-

Larger Inventory of DIN Metric Pins

Responding to customer requests, DME Company, a leading manufacturer of mold technologies, recently expanded its stock of DIN Metric Pins, Sleeves and Blades. The company now offers 9 times more inventory than it did previously, with all parts in stock and ready to ship.

-

How Moldmakers Can Reduce Production Costs and Maintain Precision

Using a mold base quick-change/hot runner combination in your mold designs can result in flexible, interchangeable precision.

-

Milacron LLC’s 2nd Anniversary Marks Two Years of Worldwide Revenue Growth

Statistics indicate ongoing success of the company’s commitment to customers.

-

SPE Mold Making and Mold Design Div Announces MoldMaker of the Year Award Recipient

The Mold Making and Mold Design Division of the Society of Plastics Engineers, Inc. presented the 2011 Mold Maker of the Year Award in Zhongshan, Guangdong China today.

-

2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

-

Alt Method of Actuating Injection Mold Core Pulls and Slides

Improve efficiency and speed with hydraulic locking core pull cylinders.

-

Best Practices for Surface Finishing

In moldmaking, the surface of the mold has a direct impact on the surface of the product being molded. Because of this, proper surface finishing is essential to producing quality parts.

-

Baffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

-

Tooling Design for Silicone Molding

One of the biggest challenges in mold design for silicone molding is the runnerless molding system or cold deck.

-

Electric Valve Gates Deliver Higher Speed and Precision

For productivity increases, faster speeds and more control over material flow, this hot runner technology is worth a look for cleanroom applications.

-

Gain Access to the Recession-Proof Medical Market

Moldmakers who want to diversify into medical—or maintain their competitive edge—need up-to-date, high-tech engineering and fabrication capabilities in order to meet the toolmaking industry’s most stringent quality standards.

-

Plate Positioning Perfected

Consider a positive precision plate device to overcome the risks and uncertainties inherent with springs and spring limiters.

-

Complex Molds Mean Business for High-Tech Toolmakers

Focus on cavitation and advanced product design gives progressive mold shops a jump on competitors.

-

Staying Competitive Using Mold Flow Analysis

The pressure on the supply chain is unrelenting for all things faster, better and cheaper. For moldmakers, getting molds built right the first time is critical to meeting these increasing demands. But how?

-

Lean Manufacturing Trims Leadtimes

Moldmakers aren't the only ones reducing leadtimes. Component and hot runner suppliers are delivering their equipment and supplies faster to accommodate industry demand.

-

Complex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

-

Mold Market Analysis

Report on the challenges and opportunities for moldmakers that lie ahead in 2008.

-

Hot Runner Technology for Bio-Resins

The polylactic acid trend, material benefits and challenges to injection molding and injection mold design.

-

A New Approach to Designing Lifter Cores: Dual-Rod Design

Benefits of using a secondary guide rod on lifter core assemblies.

-

New PET Bottle Standard May Boost Business for Moldmakers

A rule to lightweight preform necks and closures could require more than 1,000 new molds.

-

Multi-Parting Line and Multi-Material Systems

Stack molds, co-injection, two-shot molding and their opportunities.

-

The Lean Question: How Soon Can I Get Started?

Too many moldmakers are still asking,“Is this for me?” when they should be asking, “How soon can I get started?”

-

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

-

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

-

How to Make “Quick-Turn” Your Shop’s Mantra

On top of increasing production capacity, quick delivery standards save as much as five hours per project for a manufacturer of quality “quick-turn” tooling.

-

Automation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

-

Packaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

-

Hot Stuff!

Advances in valve gating technologies and improved efficiencies heat up the hot runner market in 2005.

-

Fred Steil: SPE's 2004 Moldmaker of the Year

Accolades abound from the Society of Plastics Engineers for this industry veteran who has spent his life giving back to the industry.

-

Two-Week Mold Deliveries Targeted

Quick-delivery mold builder stokes CAD/CAM production facility with mold component CAD data and technology.

-

Hanging Tough

Fallout from the recent imposition of tariffs on steel imports may raise domestic steel prices and further drive business out of the country.

-

A Stellar Hot Runner System

An off-the-shelf hot runner system helps toolmakers streak from order to shooting parts in 18 days.