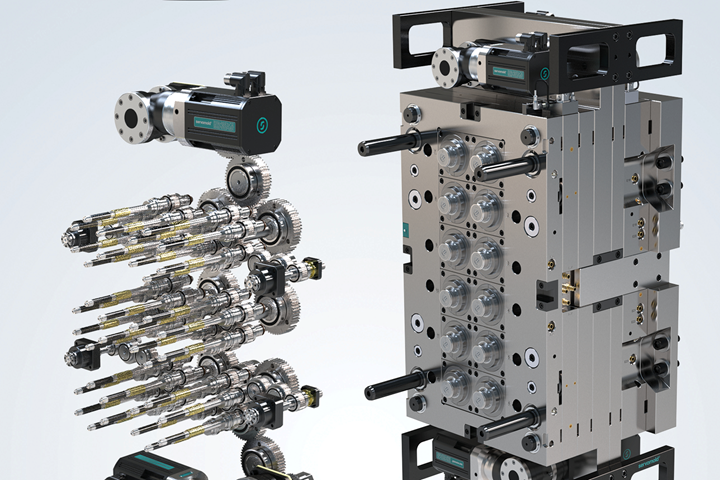

Servo Unscrewing Device Delivers High Performance to Multi-Cavity Molds

NPE2024: Electric Servomold systems by DME answer the demands made on high-performance injection molds, enabling precise, more environmentally friendly process reliability.

DME Company is showcasing the Servomold unscrewing device, an innovation that uses servomotors to drive mold actions. It offers the industry several benefits including precision and speed, energy efficiency, optimized cycle times, flexibility, reduced maintenance and a more environmentally friendly approach.

More precise control over the speed, position and acceleration of mold actions can improve the quality of the molded parts and reduce defects, DME reports. The servomotors also only use power when needed, leading to significantly reduce energy costs. Improved control and efficiency of servomotors can lead to faster cycle times, increasing productivity and reducing production costs.

The servomold systems can be programmed to perform complex mold actions, providing flexibility in the design and production of molded parts. However, the systems employ fewer moving parts and do not require hydraulic fluid, reducing their own maintenance requirements and downtime. Along with the elimination of hydraulic fluid, DME servomolds are generally more environmentally friendly, aligning with the growing trend toward sustainability in the manufacturing industry.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

.jpg;maxWidth=300;quality=90)