Mold Market Analysis

Report on the challenges and opportunities for moldmakers that lie ahead in 2008.

To get a clearer picture of the outlook for moldmakers and molders across the country and to identify the challenges facing moldmakers and the strategies of the winners, a study1 was conducted in 20072. What was discovered was a general sense that, despite a variety of ongoing challenges, the worst of the recent industry struggles may be over. Companies that adapt to the industry’s evolution will survive and grow in this new era of global competition.

Challenge and Change

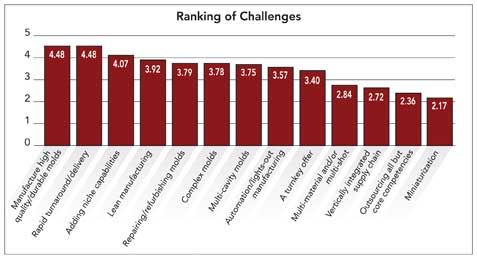

The exodus of moldmaking to overseas sources will remain the single greatest challenge to the domestic market (see Figure 1).

The shift to overseas outsourcing has been difficult for many moldmakers, but the overall feeling is becoming more optimistic. A great deal can be learned from moldmakers who are succeeding through adopting focused business plans and a variety of other growth tactics.

Moldmakers who have already adapted to the new economic climate will perform well. One global molder has adapted by reevaluating its customer base. “We have changed significantly over the past three years; our business model has moved from breadth to depth. Today, we have fewer, but larger, global customers.”

Another similarity among succeeding companies is to operate like a manufacturer, rather than a mold shop. According to one moldmaker, “our business change started 10 years ago.” He continued, “It started with a shift from mold building to mold manufacturing. We could no longer continue on with the old strategy that ours was a trade rather than a manufacturing process.”

This sentiment was mirrored by a molder/moldmaker who said, “To grow, we will have to develop a production mentality when it comes to building molds.”

Domestic Moldmakers Stepping Up

Those who believe the domestic market for moldmaking will grow cite the decrease in domestic manufacturing costs as one ground for their speculation. The research found that with the productivity gains seen in North American tool shops, prices for domestic molds will become more competitive.

One molder/moldmaker is keeping its costs under control by “running a leaner operation, taking out costs and decreasing leadtimes. All these actions strip out waste and cost, which can ultimately be passed down to the customer.”

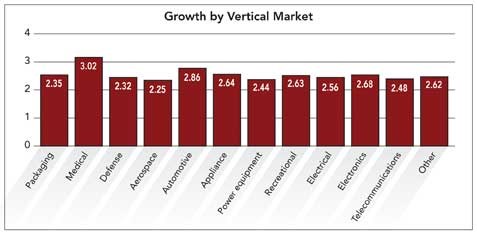

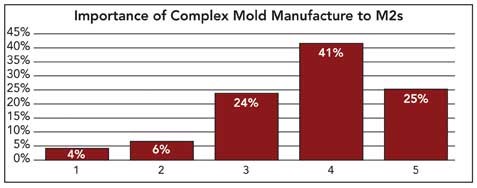

With commodity tooling from China being lower cost and the same or sometimes better quality, where do North American moldmakers have the advantage? The answer is in manufacturing complex tooling that requires advanced engineering, niche capabilities or vertical market expertise (see Figure 2). This includes anything from high-cavitation molds to making molds that serve the growing trend of miniaturization.

Moldmakers will continue to become increasingly sophisticated in practices, processes, technology, specialization and more. The research showed that to combat low-cost overseas competition, moldmakers are running increasingly sophisticated operations, deploying more efficient processes, practices and technologies. Specific actions mentioned include two-shot molding, multi-parting line and stack molds, cut heat-treated steel, MIT/Kavaform process, cast cavities, EDM, thin-wall, high-speed CNC, high-speed, high-definition hard milling, process controls and conformal cooling.

It all comes down to getting more out of the same shot, reducing cycle time, producing lighter parts, automating more and doing the same things less expensively. One industry thought leader commented, “Some moldmakers are doing a really good job at embracing technology. A handful of moldmakers really push the envelope.”

Sophisticated Business Plans

Besides sophisticated processes, strategies targeting niche markets and geographies also are leading to moldmaker growth. When asked to rate the impact 13 different factors will have on the future success of their business, moldmakers rated “adding niche capabilities” as the second most important factor, closely behind quality molds and quick delivery, which were tied for first.

The high-growth markets for moldmakers are medical, new domestic automotive, packaging and military/defense (see Figure 3). Medical molding is an ideal process to keep in the U.S. because of the complexities of working with FDA regulations. It also is becoming more important as the baby boomer generation ages and requires more medical care.

A smaller molder/moldmaker interviewed found this to be the perfect niche, “We got into the medical industry because of the high tolerance nature of our business. We are confident our growth will come from close tolerance, complex molds.”

The Northeast and West—especially California—are experiencing high growth in the medical molding market, making those areas two of the three most prominent regions for molding and moldmaking growth in the country.

The third and largest growth area is the Southeast, fueled by the booming new domestic automotive industry made up of Toyota, Honda, Nissan and others. This region is supported by an accommodating employment environment including many Right to Work states.

Molds are increasingly made where the molders are. Moldmakers and suppliers are finding that they need to be geographically close to customers to provide the level of support they demand. With the growth in the Southeast, Northeast and West, successful moldmakers are looking to expand their operations to include nearby production and support in these regions.

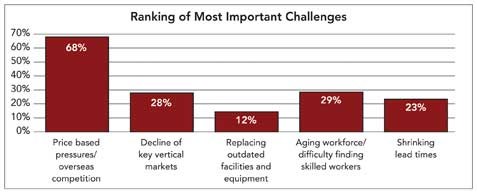

Like many other industries, moldmakers will face a labor shortage, as first- and second-generation experts retire. Even in the most promising markets and regions, one emerging challenge looms for all: the labor shortage created by retiring first- and second-generation moldmakers (see Figure 4). The research showed 29 percent of moldmakers ranked “aging workforce/difficulty in finding skilled workers” as a five on a one-to-five scale (five being the most significant challenge that they will face in the future).

The good news is that thriving moldmakers are in action to fill the labor and knowledge gaps through a combination of training and more efficient processes. Toolmakers are finding it hard to recruit—across the board, no matter what size company or region we looked at. To counter the lack of people interested in the industry, some successful strategies included in-house training, apprenticeship programs, partnerships with local schools/tech colleges and reliance on suppliers.

One molder/moldmaker taking this approach said, “We do a lot of internal training and internal development. It takes longer, but on the upside, it creates better employees.”

The other way to counter a smaller workforce is the implementation of processes and technologies that reduce labor in the molding process such as Lean, Kaizen and automation.

One moldmaker that is incorporating both strategies explained, “We’re dealing with the labor shortage on two fronts. First, we’re automating as much as possible and second, we’re doing more training ourselves than in the past.”

Signs of Progress

Despite the general decline predicted on the surface of some of the research data, the underlying signs of progress in the industry are many and varied. Companies that are ready, willing and able to adapt will do so, and they’re likely to grow and prosper amid the new economic realities of North American moldmaking.

References

1Study Demographics: The third-party research study consisted of 33 in-depth interviews and 429 survey participants. The participants comprised a cross section of industry thought leaders, molders, moldmakers and molder/moldmakers. Operations included both large and small shops serving a variety of end markets. Participants’ roles ranged from owners to operations and engineering personnel.

2Research commissioned by D-M-E Company and Milacron.

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreRead Next

The Lean Question: How Soon Can I Get Started?

Too many moldmakers are still asking,“Is this for me?” when they should be asking, “How soon can I get started?”

Read MoreNew Business Model Required For Mold Manufacturers

Annual study shows changes in the moldmaking industry and provides insight to help make the right decisions for your shop.

Read More