Staying Competitive Using Mold Flow Analysis

The pressure on the supply chain is unrelenting for all things faster, better and cheaper. For moldmakers, getting molds built right the first time is critical to meeting these increasing demands. But how?

Mold flow analysis is a sophisticated practice that’s gaining popularity. It helps identify a variety of potential problems and improvements for a mold before it gets built. The results are less risk involved, more time and money saved in adjustments and faster delivery. Here’s a look at how Norwich, CT manufacturer Plas-Pak is enjoying these advantages through mold flow analysis.

Challenge and Solution

Plas-Pak makes disposable syringes, dual syringes, cartridge dispensing systems, adhesive dispensers, static mixers and spray systems. The company operates 24 hours a day, five days a week, but even with all that production time, every second counts.

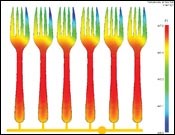

Plas-Pak was looking for a way to meet the increasing demand for one of its large cylindrical parts for the industrial epoxy market. The company set a goal to decrease cycle time and minimize part warping by changing the gating system and cooling channels for the mold. To make sure it got these precise changes right upfront, Plas-Pak and its moldmaker, B&D Machine of Tolland, CT, turned to D-M-E Company to run a mold flow analysis.

Based on projections, a new mold using mold flow analysis could reduce cycle times by 17 percent while also eliminating part bowing. Through mold flow analysis, Plas-Pak identified the need to switch to a valve gate system, change gate position and modify the cooling channels. In the end, cycle time exceeded expectations and was reduced another 18 percent on top of the projections.

“Without this analysis, there are adjustments and location changes we never would have done,” says Brent Giansanti, product development manager and engineering manager at Plas-Pak. “It was really exciting to be able to get the cycle time for this challenging part reduced by 35 percent.”

Computer Simulation of Injection Molding

Moldflow Plastic Insight (MPI) is a computer simulation of injection molding that “helps us begin to understand what is going on inside the mold,” according to Rick Millette, D-M-E field service representative.

Simulating the way a material will actually flow through a mold before it’s ever built ends up saving time and money in the long run. It’s particularly valuable for any product with varying wall thicknesses, surfaces or challenging part geometry.

“Any time I have a product that has some difficult geometry, I always want to make sure I pick the right place for the gate, core and flow,” notes Giansanti.

This accuracy becomes even more important when competing with low-cost overseas moldmakers. Plas-Pak doesn’t find itself in that position at the moment, but it’s an increasing concern for moldmakers across North America. Even though a complete mold flow analysis costs between $1,000 and $2,000 and takes a few extra days, the practice can pay off quickly, in both time and money.

Without mold flow analysis, the whole process is more about trial and error. Moldmakers have to start with small gates to fill their mold and keep increasing the size little by little until the mold gate is the correct size. Besides wasting time and money, that also creates more backpressure in the mold, which creates core shift. It’s an expensive, inefficient way to determine the appropriate gate size: you have to take the mold out of the machine each time, modify the gate and put it back in. In the process, you also create more scrap and bad parts.

The Expertise to Get the Job Done Right

Plas-Pak now uses mold flow analysis for about 50 percent of its molds. “It’s come to a point in our industry where it’s necessary to perform mold flow analysis on many tools to make sure its right the first time,” explains Giansanti. “We’ve had occasions when a tool was built and it wasn’t a good design, and we can’t afford that anymore.”

But that wasn’t always the case. Up until a year ago, Plas-Pak was skeptical of the process. Then the company purchased the mold flow analysis from D-M-E in combination with a hot runner system for the large cylindrical part, and Plas-Pak’s perspective changed.

D-M-E employs the industry’s most advanced mold flow analysis engineer, Sandy Huang. Huang, an applications engineer with 14 years of experience in mold design and is certified at mold flow’s highest level. She even advises software developer Moldflow Corporation on improvements for the program.

“Mold flow is a complex and careful process,” Huang says. “You can’t just push the buttons and run the software. You really have to analyze and judge the results. It’s about extracting the right information to help the customer.”

For Plas-Pak, Huang says the challenge was to figure out whether one gate could fill the part while completely minimizing warpage, and if one gate could do the trick to identify the exact location needed for the gate.

Summary

In the past year, the 50 percent of the new molds at Plas-Pak built after running a mold flow analysis have required no adjustments after the initial build. That’s quite an accomplishment, one that could save a great deal of money and headaches for moldmakers, molders and OEMs.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

Integrating Hot Runner Mold Construction

Realize time and cost saving benefits from the use of integrated systems when compared to traditional hot runner manufacturing methods

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)