Alt Method of Actuating Injection Mold Core Pulls and Slides

Improve efficiency and speed with hydraulic locking core pull cylinders.

More sophisticated tooling technologies are always evolving. One advancement that improves efficiency and speed is a hydraulic locking core pull cylinder. By employing this method of actuating a core pull, molders can take advantage of smaller mold bases, and at the same time, reduce overall costs. This article will demonstrate how hydraulic locking core pull cylinders can actuate core pulls and mold slides in injection molds with much less design, machining, fitting and maintenance time than traditional slide assemblies.

Accommodate Smaller Mold Bases

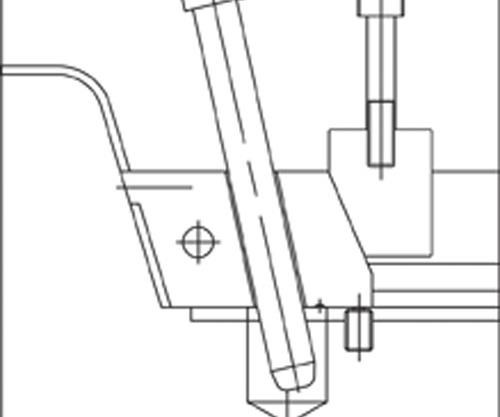

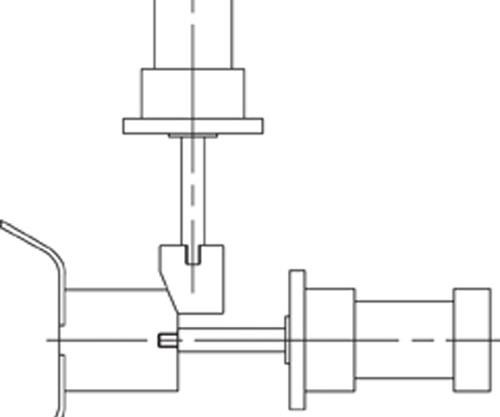

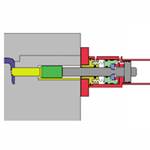

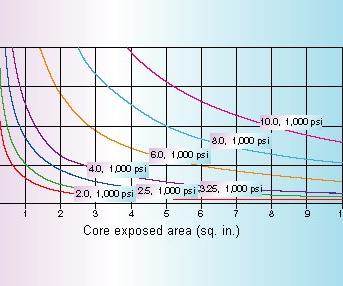

When designing molds with sliding cores, the mold designer is often faced with the challenge of fitting all traditional components in as small a mold base as possible. There are different methods of actuating a sliding core. The most common of these use horn or angle pins (see Figure 1) to move the slide when the mold opens or closes. Heel blocks (wedges) are normally used behind the sliding core to withstand injection pressure acting on the sliding core. Unfortunately, these components both use up precious mold space and are tied to the movement of the platen. Some molded parts also require that the sliding core be moved prior to opening a mold. While it is possible to use standard cylinders (Figure 2) to actuate the sliding core or heel block, typical designs require additional mold design and machining, and waste mold space.

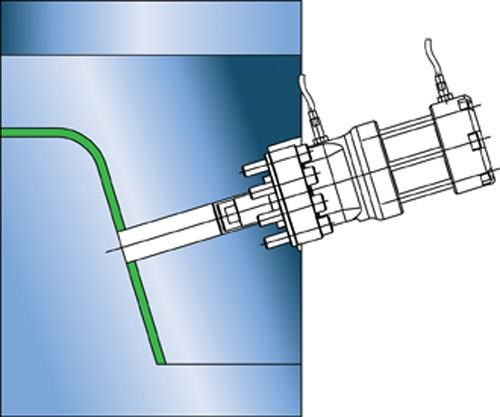

An alternative is to use a hydraulic locking core pull cylinder that replaces traditional slides and heel blocks. The cylinder enables independent movement of the sliding core and completely eliminates the need for wedges. It uses a segmented ring that presses into an internal groove within the cylinder assembly while in closed position. As a result, the injection pressure from the part cavity acts against the cross-section of the segmented ring, locking the slide without needing a heel block. Eliminating separate heel blocks or additional cylinders can result in a smaller mold base size—simplifying mold designs, reducing material costs and increasing overall cost savings.

Lessen Material Shrinkage

Another key benefit is that the opening movement operates independently of the mold opening. The piston can be retracted before the mold opens, resulting in reduced cycle time. This function also gives molders the ability to pull the core before opening the mold, which can help lessen material shrinkage. For example, when injected material begins to shrink within the mold, not being able to pull the core, as with traditional assemblies, often compounds that shrinkage even further.

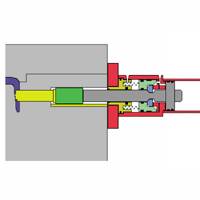

A hydraulic locking core pull cylinder has a compact design (see Figure 3), further enabling smaller mold bases. Due to its modular construction, special strokes are available for custom applications, specifically when shorter strokes are needed. The modular design also enables easy modifications and customization, and if the tool needs to be removed or exchanged, it’s easy to re-install it to the same specifications.

Reduce Mold Design and Build Time

A hydraulic locking cylinder provides other time and cost savings when used instead of other methods. Designing a core pull using horn or angle pins is a highly technical, time-consuming process involving calculating compound angles, machining the slide, incorporating final fitting to ensure the slides don’t move, and many other intricacies. Since slides are not standardized, each one has to be formed based on available space and it’s easy to make mistakes.

Mounting a hydraulic locking cylinder takes much less mold design and manufacturing time and less mold fitting and assembly time. It also dramatically reduces maintenance time for molders. In a traditional core pull system, there is substantial metal on metal contact among wear plates, gibs and the angle of the slide that contacts the heel blocks. These components eventually need to be replaced at the expense both of repair and downtime.

The only movement in a hydraulic locking cylinder is the piston itself. The metal slide comes in contact with a seal rather than wearing on other metal components, resulting in less maintenance time and cost.

Minimize Risk

When using hydraulic locking core pull cylinders, it is important to always sense when the sliding core is in its full forward and fully retracted positions. If this is not done, there is a risk of opening the mold before the core is fully retracted, or attempting to inject into the mold before the core is fully forward and locked.

It is typically recommended to use proximity sensors standard to core pull cylinders to recognize full forward and full reverse. With proximity sensors installed, the cylinder assembly can withstand temperatures up to 176ºF (80ºC). If it is necessary for the assembly to withstand higher temperatures, the proximity sensors can be replaced with plugs and an external method for sensing sliding core position can be used. By doing this, the cylinder assembly can withstand temperatures up to 356ºF (180ºC).

Ease Installation

A hydraulic locking core pull cylinder uses an integral flange that mounts to the mold using socket head, UNC-type cap screws, making it easy to install to very precise specifications.

Installing a spacer plate (shim) beneath the flange enables fine adjustment in the mold as it can be ground to the exact tolerance. The spacer plate also provides important preload on the cylinder rod, particularly when the sliding core must shut off against the opposing wall of the core. Hydraulic fittings are NPTF-type fittings.

Due to the nature of the flange mounting design, the same size cylinder is easily interchangeable; and, the flange and screw mounting method ensures that the proximity sensors will always be positioned in the same orientation when the cylinder is installed to the side of the mold.

Summary

Since technology is always advancing, it is important to be aware of technology that can reduce cycle times and increase cost savings. A hydraulic locking core pull cylinder is an alternative method of actuating core pulls that offers numerous advantages to mold designers, moldmakers and molders: capability of providing pre-loads; integral mounting flange and front cylinder head; spacer plate (shim) for accurate final setup; positive mechanical lock; large locking surfaces for long service life; interchangeable cylinders; and, high degree of accuracy.

Related Content

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

Mold Side-Actions: How, Why and When They Work

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.

Read MoreMold Side-Actions: Applications Rule the Action

With a firm understanding of the effects of injection on the core, slide and associated components, this second of two articles will discuss emerging modular technologies which provide alternatives to the limited solutions previously available.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More