Amerimold 2017: Multitudes of Metalworking Materials and Machines

Amerimold proved once again that it is THE event for moldmaking.

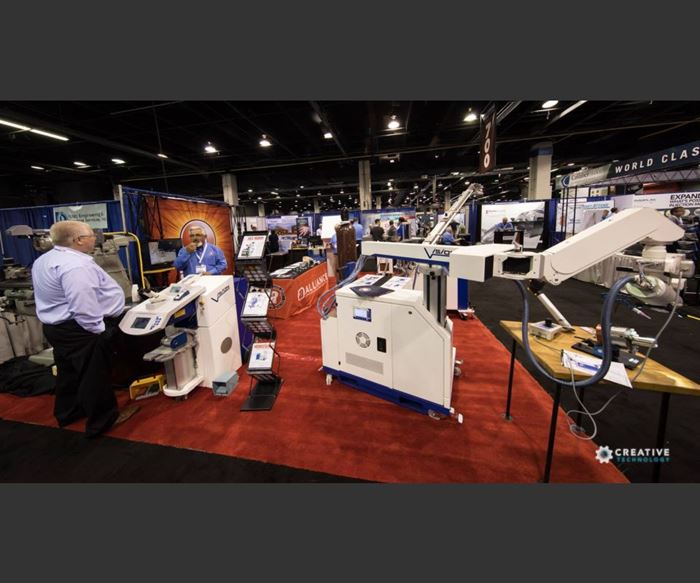

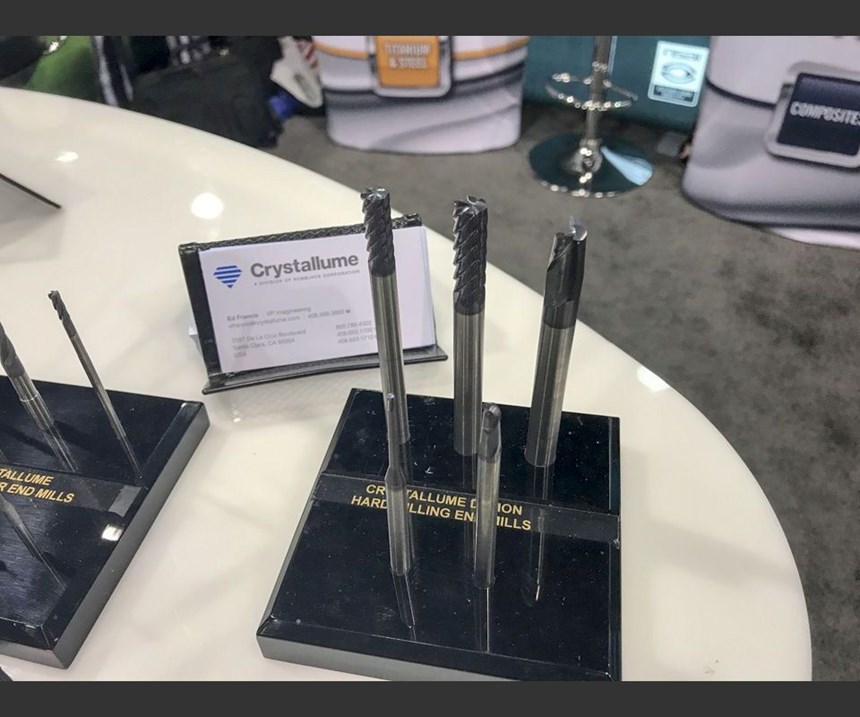

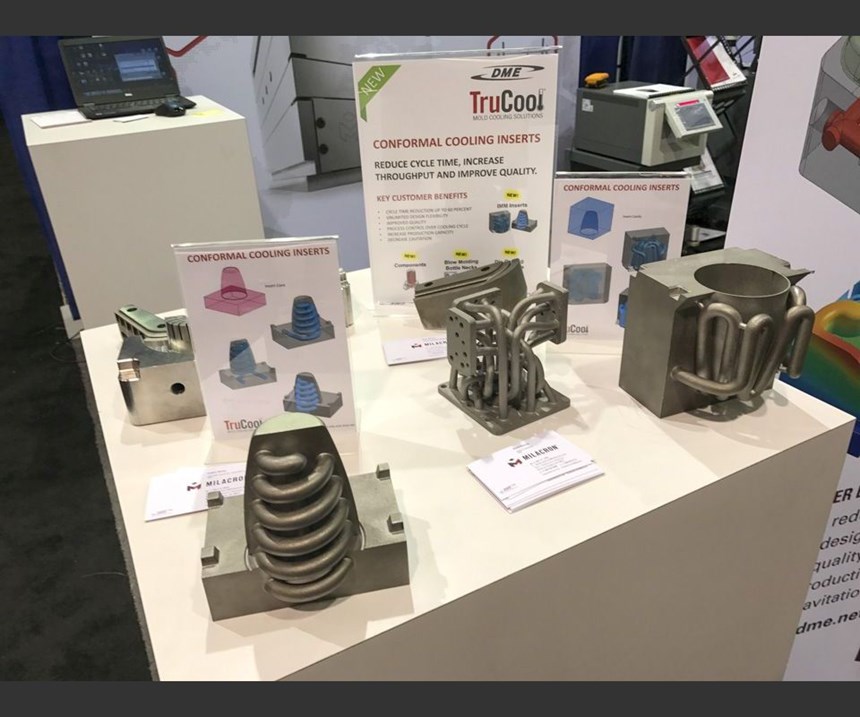

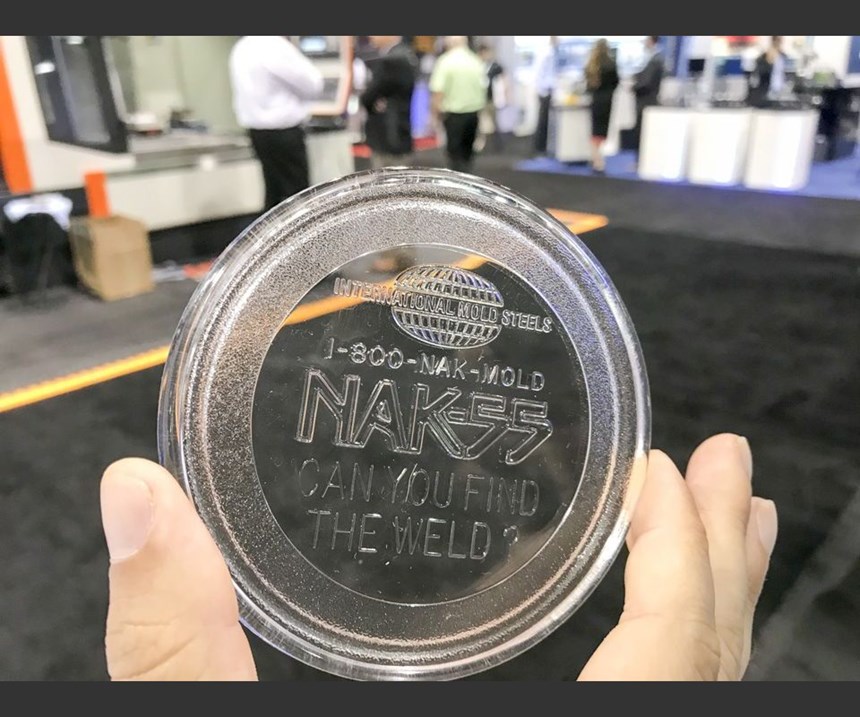

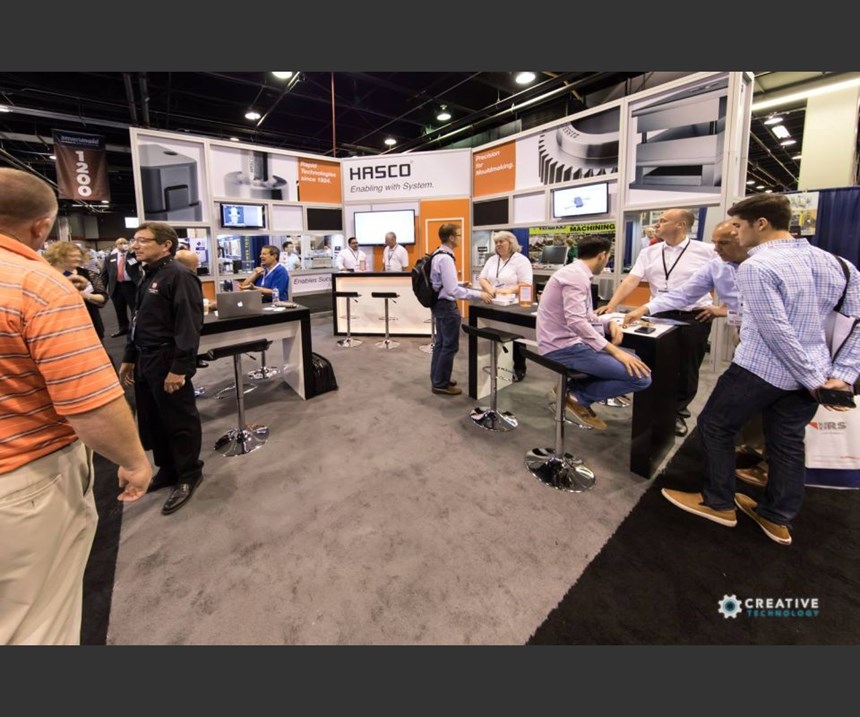

Amerimold proved once again that it is THE event for moldmaking. Whatever aisle one ventured down during Amerimold on June 14-15 in Chicago, displays of cutting tools, machine tools, mold materials and components, EDM supplies and so much more filled the senses. Attendees commented often about how large Amerimold has grown, and with more than 200 exhibitors, they’d be correct.

Today’s review of Amerimold focuses on metalworking-related products and services that could be found along each aisle, and readers can expect more slideshows featuring other highlights through the end of June. It is our hope that those who were unable to join us this year will appreciate a nice overview of what was missed (and we hope they will join us next year in Novi, Michigan), and those who did attend will find these blogs to be helpful reminders of products and services showcased.

Related Content

-

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

-

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

.jpg;maxWidth=300;quality=90)