A Stellar Hot Runner System

An off-the-shelf hot runner system helps toolmakers streak from order to shooting parts in 18 days.

Say "hot car," and you think "fast." Say "hot runner," and if you're a toolmaker, you think nail-biting delays. But toolmakers such as Imperial Tool & Manufacturing (Lexington, KY) can really "smoke their tires" now with new off-the-shelf hot runners from D-M-E (Madison Heights, MI), according to Imperial Vice President David Meeks. Meeks was one of the first users of D-M-E's new MeteorT hot runner system in August 2000, enabling him to get a tool into production for a critical part in just 18 days for nearby customer Prime Finish, a high-end decorator of consumer electronics hardware.

Prime Finish LLC specializes in robotic spray painting, pad printing, 3-D Dip-PrintingT and other decorative techniques that give an OEM's product extra visual impact and perceived value at the consumer level. A young company started in the fall of 1999, the Paris, Kentucky-based firm employs about 50 people, and operates out of a new 26,000-sq.-ft. plant.

"With consumers always chasing the latest 'new look,' and product life cycles getting ever shorter, we have to turn things quickly for our OEMs to hit the window of opportunity," says Richard Ramsdell, Prime Finish materials engineering specialist.

Fast production can't come at the expense of scrap rate, however. "Our business is about production yield as much as it is speed, creativity and visual impact," says Ramsdell. "Every scrap part comes out of our bottom line because we don't work with consigned inventory. We purchase the parts, decorate them and sell them to someone else in the supply chain." Thus, industry-beating production yield is how Prime Finish has earned its market share against entrenched competition. "Our industry would consider 90 percent a good yield, but we can consistently beat 95 percent," Ramsdell states.

Proprietary techniques are key to Prime Finish's mass production with high yields, and one of those techniques uses a perishable polypropylene (PP) process component. The performance of this part is critical to Prime Finish's productivity and yield. "This part is baked to nearly 200xF under load - annealed, if you will - two or more times, and it has to retain its shape perfectly, so molded-in stress has to be controlled and absolutely consistent from part to part," Ramsdell explains. For this and a variety of other reasons, Ramsdell is a strong advocate of hot runner tooling. "A sprue and runner add variables to your fill and pack which affect molded-in stress; they increase cycle time because they have to be cooled; and they're wasteful," he adds.

The PP components have to be precision-molded on short notice when the customer gives a "go" on a production run, so Ramsdell prefers to work with a development shop like Imperial, a toolmaker who can also do short runs of parts. "I firmly believe in a molding shop that's affiliated with a toolmaker, so it's in the interest and capability of the molder to take care of the tool. This greatly compresses our delivery cycle and eliminates finger-pointing between a molder and a toolmaker," Ramsdell says.

Imperial Tool fit that bill perfectly as a builder and maintenance operation for all types of molds and dies. Founded in 1966, the company specializes in quick-turnaround mold building, with high-speed machining equipment for electrodes, cavities and cores, as well as CAD/CAM capability.

Imperial also has a spin-off molding business - Modern Molding Technology, Inc. (MMT) - next door with two all-electric Milacron ACT injection machines of 75 and 100 tons. "We started MMT as a value-added service to our customers for mold prove out and prototyping, and we've successfully built it up to a 24/7 production operation," notes Imperial's Meeks. "MMT, combined with Imperial, is a huge asset to our customers, allowing 'one stop' mold building and prove out to reduce development time. The all-electric machines have no variability or quirks like hydraulic machines, so our customers get a very reliable picture of how a mold will perform. The machines' exceptional shot repeatability, no need for warm up of hydraulics, no loose oil or the inconsistency of hydraulic drives allow us to prove out a mold with a high degree of confidence. And the machines can keep performing like this around the clock, giving us dependable quality and repeatability when we're running 'lights out' production."

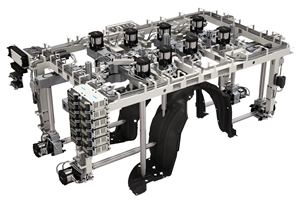

By coincidence, Meeks was with his D-M-E rep learning about the off-the-shelf Meteor hot runner program when Ramsdell called for a quote and delivery time on a mold for some processing components. Based on experience with similar parts, Ramsdell and Meeks agreed the mold would be a two-cavity hot runner on 4.5" centers. "We quoted the job in 45 minutes, and soon thereafter got a partial database for the part, which we had to improve significantly in SolidWorks before going to Mastercam for the toolpaths. The part is relatively simple in that it has no radical wall thickness variances, but it does have compound curves."

Meteor systems are designed as two- and four-drop configurations, and are suitable for both commodity and engineered resins. The pre-engineered and pre-manufactured manifolds are less expensive than custom hot runner systems, enabling a molder to easily justify prototype projects or applications with lower production volumes.

The standard system is available with a machined main flow channel, but allows the toolmaker to machine nozzle locations and fit the end plugs. Six in-line sizes and four "X" style manifolds are available. The Meteor manifold can be integrated into a complete hot runner system, with everything needed to build a system, including nozzles, supports, nozzle seat, locator ring, thermocouples and other components also available to ship the same day. Nozzle selection can be made from a broad range of D-M-E standards, too.

"We were able to put the mold in the machine and shoot parts in 18 days, and it all worked from the first shot," says Meeks. The part requires about a 12-gram shot of 30 percent talc-filled PP, and it runs on about a 15 cycle. "It's nice to know that we can now cut time on these jobs without cutting corners."

Related Content

How to Build a Better-Performing Hot Runner Mold

Early stage communication across the supply chain about design considerations optimizes hot runner mold performance.

Read MoreSix Key Factors for Evaluating a Hot Runner System

Details matter when it comes to selecting and integrating a hot runner system. This guide makes that process easier by covering those details thoroughly.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More