Photo credit, clockwise from top left: Mastip, Husky Technologies, SelfLube and Meusburger

The Plastics Technology Expo (PTXPO), taking place this year March 28-30, 2023 at the Donald E. Stephens Convention Center in Rosemont, Illinois, brings partners across the supply chain together.

The MMT team put together this special show section* that provides a snapshot of each exhibitor most relevant to moldmaking. This profile focuses on mold components and hot runners, highlighting the exhibitors who will be showcasing their innovations and technology in this area at the show.

Each profile shares details important to the company’s business and innovations, including why and what they are exhibiting at PTXPO in or around the MoldMaking Pavilion. Exhibitors located outside the pavilion are denoted with two asterisks and information on where to find them.

Use promo code MMT23 and register today for your FREE exhibit hall pass and we’ll see YOU in Chicago!

*This exhibitor list is subject to change. Current as of 2/9/23

Get to Know CUMSA USA LLC

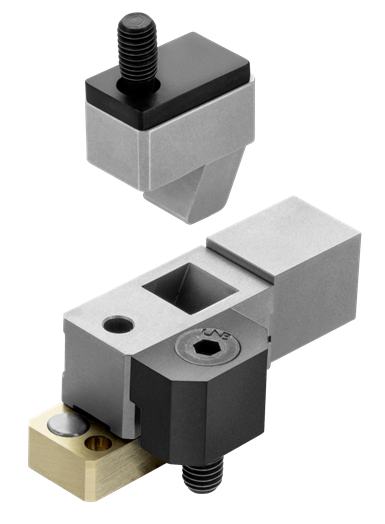

The introduction of standard components for injection molds has been a critical innovation for the moldmaking industry. CUMSA is pleased to have contributed to this marketplace by developing many standard mold components that save time and money for the mold designer, mold builder and molder.

For mold designers, it’s easy to use standard components in projects and drawings because they are available digitally and quickly downloaded to incorporate into designs. For mold builders, standard components help reduce the time needed for mold construction and machining because they are off-the-shelf products ready for purchase and mold installation. For molders, when a unit is worn or broken (and they know who produced it), they can easily find a replacement part via an identical part number that has the same dimensions, quality and materials.

Photo Credit: CUMSA

The CUMSA team is privileged to be a part of this industry, as moldmaking has been their passion for the past 45 years. They understand that moldmaking is a challenging business where technology is continuously evolving, so they like to take some of these challenges and transform them into products that can bring solutions to users.

The CUMSA team enjoys looking at each problem individually and finding innovative and advanced solutions to help mold builders make their mold construction easier, less expensive, faster and with the best quality possible.

Visit Booth 1516 to see the display of new products, get questions answered by technical staff and view product animations, videos, catalogs and literature.

Get to Know DMS

Attendees can expect the unexpected at Booth 1531. DMS has over a century of serving the moldmaking community, with industry experience in mold polishing, component cooling and gas venting technology. Promotional coasters will be available for visitors, and a PTXPO-related promotional mold plaque will illustrate the company’s innovation in this area.

Mold plaques were nothing new in 2008, but they were primarily laser engraved and difficult to read. DMS introduced full color, high-heat thermal set mold plaques to the North American (NA) market. This was to help distinguish NA molds from overseas molds and provide exterior mold information — sequential steps, warnings, cautions, electrical, waterlines, shop branding, etc. — at an economical price point. Within the past 15 years, full color plaques have and continue to make an impact.

Photo Credit: DMS

Additional innovations introduced to NA moldmakers include solid bronze bushings, ball-guided ejector bushings, standard off-the-shelf extra-length leader pins, Metal Rust Guard Preventative Mold Wrap, MIM standard one-piece tunnel gate inserts, REDE Vault mold data storage units, Worm gear assemblies and Koolflow modular water manifolds.

DMS is proud to be strong supporters of industry associations, such as AMBA, and is a founder of CAMM.

Get to Know Hasco

Hasco is showing the latest in smart components for moldmaking — agility, innovation, simplicity and performance. Visit Booth 1409 to see how Hasco enables customers to easily design and build with these quality components.

With stock available in worldwide locations, Hasco shows you how easy it will be to design, build and run your injection molds. The Hasco team will include U.S. account representatives, along with the 2019 SPE Mold Designer of the Year, to discuss your projects.

Photo Credit: Hasco

Moldmaking is important to the Hasco business because it is its passion and history. It is a way of life for the employees and customers. Since its founding in Lüdenscheid in 1924, Hasco has become an internationally leading supplier of modular standardized components and accessories. With this in mind, the company designed the standard mold base that made Hasco a recognized industry pioneer. With the invention of the modular standard component system, the company has defined international standards and revolutionized moldmaking with mold components, mold plate and hot runner systems.

The new Hasco web portal makes it easier to quote, order and research new parts in helping the customer retain their specific history. The complete range of plate movement and positioning now uses the highest quality DLC coating to enable a dry run mold design/build for most cleanroom applications. Hasco realizes that certification and documentation is important for quality control and is using the latest digital advancements on these components.

**Find Hasco alongside the Moldmaking Pavilion

Get to Know Incoe Corp.

Visit Booth 1330 to meet with the Incoe team to discuss solutions to your hot runner part filling challenges. Come learn about Incoe’s SealFit technology, SBH — slim base heaters, HEM — hydraulic miniature VG cylinders, unitized and hot half hot runners and advanced part fill simulation.

Photo Credit: Incoe

Incoe has remained focused on its partnership with moldmakers since 1958 from the first design step through to preventive maintenance, providing precision, durable and high-performance hot runner solutions. The company has improved melt delivery implementation, maintenance and performance with technology solutions that address melt rheology management, use of exotic materials and geometries, PIDD controllers for improved homogenous heat distribution, heat insulation/ isolation, temperature control and valve gate pin velocity retraction control, and much more.

Get to Know Meusburger US Inc.

For more than 55 years, Meusburger has recognized and catered to its customers’ needs for standardization in the mold and die-making industry, delivering high-precision standard parts and selected products for workshop equipment, hot runner systems, control systems and systems in the areas of WBI Knowledge Management and ERP. This has made Meusburger a reliable global partner for making molds, dies, jigs and fixtures.

Meusburger has years of expertise in working with steel. The company heat treats all of its plates and bars for stress relief which guarantees the reduction of plate warping during machining. Stress-relieving heat treatment therefore reduces lead times, increases precision, results in cost savings and thus provides a competitive advantage in the long term for Meusburger’s customers.

Photo Credit: Meusburger

Visit Booth 1622 to connect with Meusburger’s experienced and knowledgeable professionals and learn how the company can offer you support in your moldmaking needs and applications. The Meusburger booth display will mainly consist of components for moldmaking, include guiding elements, ejectors, slide systems, temperature regulation, locks, demolding elements, change mold and hot runner controllers.

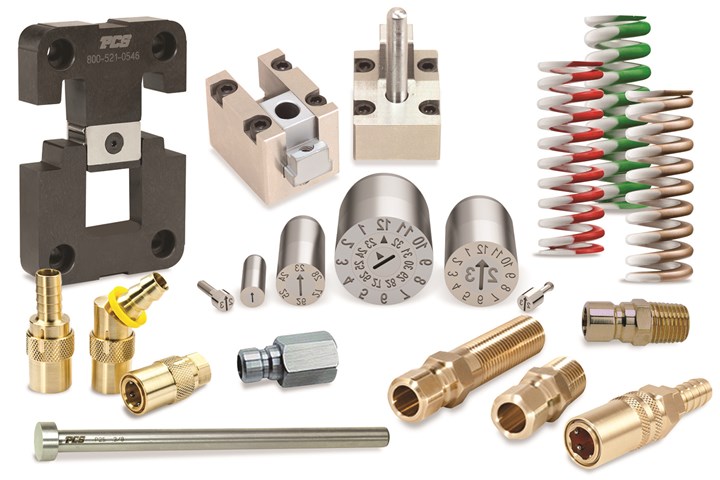

Get to Know PCS Company

PCS Company is a leading one-stop shop products supplier for the North American moldmaking industry for mold bases, mold components, hot runner products and more.

The PCS Standard Mold Base Configurator, for example, has proven to be one of PCS’ major innovations to the industry. It has enabled users to go visit the company website and order what they need in just three steps. Users are also able to download the CAD drawing of the configured mold, review the bill of materials, generate a quote and save all of this information to access later.

Attendees at PTXPO can see the latest technologies and changes in the industry at Booth 1123. PCS will be displaying a wide variety of its moldmaking products and will show numerous how-to videos as well, aided by its personnel which have decades of experience.

Photo Credit: PCS Company

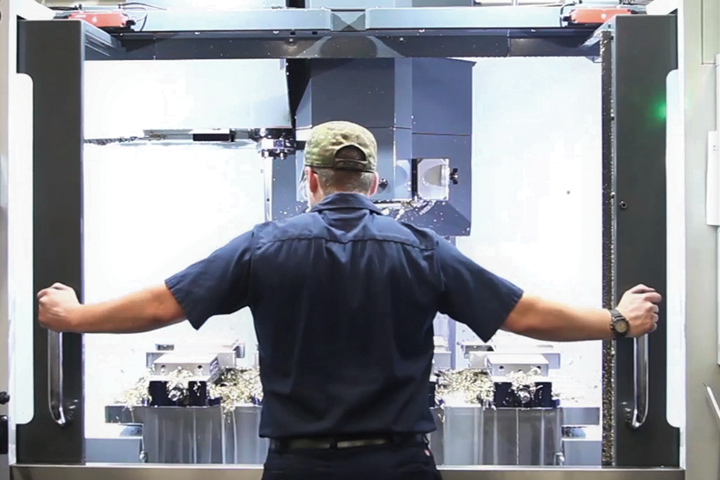

Get to Know SelfLube

Visit Booth 1524 for a comprehensive product showcase and to meet SelfLube’s knowledgeable and friendly leading experts. SelfLube manufactures components for molds, serving an industry that is as vital to its team as it is to everyone else — although it may appear to be a small and insignificant industry, moldmaking impacts our everyday life. Virtually every tool that surrounds you is made within the tooling industry. By increasing productivity with mold and die components, we increase value within ourselves and society as a whole.

Photo Credit: SelfLube

SelfLube has continuously improved itself over the last 30 years; innovation for the company tends to happen steadily over time, small improvements collectively becoming rather substantial.

On a collective basis, the company’s most significant innovation that impacts moldmaking is the development of a high-mix, low-volume manufacturing environment. Over the years, SelfLube says it made adjustments to everything, like order processing and specialized software to personalized training. This enables SelfLube to reliably and effectively handle all of its customer’s needs. This also permits customers to free up their resources and prioritize their work building the actual tool.

Get to Know Yudo Inc.

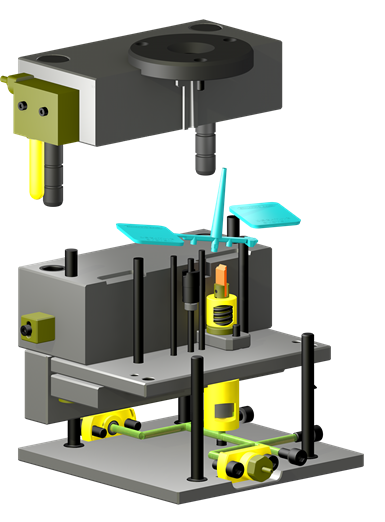

From mobile, home appliances and automobiles, to packaging, medical and industrial products, Yudo’s technologies related to the North American moldmaking and plastic injection molding industries are reflected in the world around us. Yudo specializes in hot runner systems that produce environmentally friendly products that reduce the waste of resin. Its products are applied in various industries to improve technology and quality and to make products more beautiful, convenient and safe.

Photo Credit: Yudo Inc.

With over 40 years of accumulated know-how and experience and more than 400 patents, Yudo has various strengths for customer satisfaction. The company pursues professionalism in all processes to provide products and technologies optimized for various industries. In addition, each process includes inherent flexibility, providing high-quality products and services to customers.

Yudo highlights its recently introduced ISO manifold manufacturing technology, which makes a flow channel customized for any product shape. ISO optimizes hot runner balance by implementing a smooth and flexible flow channel design, eliminating any dead spots and providing a smooth, uninterrupted path for the plastic to flow from the machine nozzle to the cavity.

Visit Booth 1227 to see Yudo’s product sample parts supporting technical inquiries and application discussions. A cutaway of the company’s ISO manifold technology will also be on display. The booth will be staffed by industry professionals that bring many years of experience to the table to help you work through all of your unique applications.

Related Content

Technology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreVIDEO: Taking a People Before Product Approach to Growing a Business

Angela Elsey, President of PCS Company, shares her journey into moldmaking, perspective on the industry and plans for the business.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreRead Next

Where Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

Read MorePTXPO Preview 2023: Upcoming Software/Simulation Services, Training and Marketing Solutions

This latest installment of PTXPO snapshots feature companies in and around the Moldmaking Pavilion powered by Amerimold that provide industry solutions in software, simulation, training and marketing.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More