Baffle Blades in Plastic Injection Molds

Turbulent-flow plastic baffles eliminate blow-by, significantly improving cooling and cycle times.

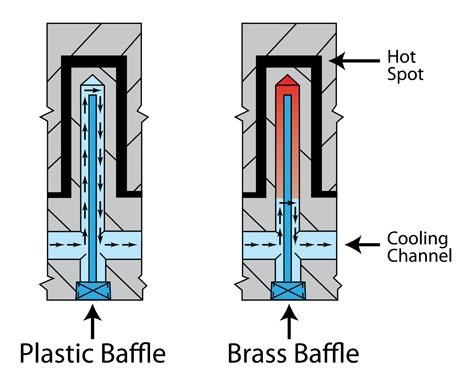

Cooling products—couplings, baffle blades, bubbler tubes, etc.—have traditionally been made with brass materials. In the case of baffle blades; however, brass has significant drawbacks that make it difficult to achieve maximum heat transfer. A new material—polypthalamide—offers a dramatic improvement in the performance and features for baffle blades used in plastic injection molds (see Figure 1).

Polypthalamide

Polypthalamide, an engineering thermoplastic, is a member of the nylon family with excellent high temperature properties (heat deflection temperature of 280oC and a continuous use temperature of 170oC). Polypthalamide also provides excellent resistance to chemicals including fuels and glycol. Thanks to these mechanical properties, polypthalamide has been refined and developed for use in glycol-based, high-temperature applications—specifically automotive radiators.

Temperature gradients and temperature cycling are the biggest challenges for materials used in cooling systems, and polypthalamide has proven to be up to these challenges in automotive cooling systems around the world. Polypthalamide also has good chemical resistance properties, particularly with respect to glycol-based coolants commonly used in automotive and injection mold cooling systems. Thus, polypthalamide is an ideal material for use in thermoplastic injection mold cooling systems.

Brass Baffles Blades

Mold cycle time tends to be driven primarily by the length of time it takes to cool the plastic material until the part can be ejected from the mold. The sections of the molded part that take the longest to cool are the hot-spots.

Brass baffle blades have been used the same way for decades—to redirect coolant flowing through a cooling channel into another intersecting cooling channel. The most familiar application of the baffle blade is as a pointer to a hot-spot in a mold, improving overall cooling efficiency.

The most common arrangement for mold cooling design is a series of cooling channels that run parallel to the parting line, or molding, surface. Occasionally, as dictated by molded part geometry, it is advantageous to reroute the coolant flow up toward the parting line. A molded part with deep-draw geometry—a drinking cup, for example—will cool better if coolant is directed up into the standing core shape, the interior of the drinking cup in our example. The baffle blade is a proven method for redirecting coolant flow in these cases.

The baffle blade is essentially a bidirectional, straight line, from a coolant channel to a hot-spot and then back to the coolant channel. The blade splits a bored cooling channel into two half-circles. When the coolant runs into the baffle blade, it is redirected into the first of these two half-circles. The coolant travels up the front side of the baffle blade and is then redirected, 180o, onto the back side the baffle blade. The coolant then flows back to the coolant channel and continues on its way through the mold cooling system.

Mold Designers and Mold Cooling Systems

When designing cooling channels for a mold, the mold designer is frequently looking at deep-draw sections of a molded part and attempting to get as much heat as possible out of these areas. They tend to be the hottest of the hot-spots in most molds. The best way to get the heat out of the deep-draw sections of the mold is with baffle blades.

Almost all toolmakers cool molds the same way—with drilled cooling channels. Brass baffle blades tend to be about 0.095” thick, with about 0.020" clearance on each side to allow the blade to be screwed into the threaded tap at the end of the drilled cooling channel. As the clearance is necessary for installation, the gap cannot be eliminated.

Fluid Flow in a Mold Cooling System

Fluid dynamics assert that fluid will travel the path of least resistance, and that is the case with coolant flowing through a mold cooling system. Coolant will use the gaps between the baffle blades and the coolant channel as the preferred route of travel, rather than flowing all the way to the top and over the baffle blade as the mold designer intended. This is commonly referred to as blow-by.

When blow-by occurs, the coolant tends to stagnate past the area of the blow-by. At a minimum, the coolant flow on the other side of the blow-by will be greatly reduced. This stifles the thermal transfer capabilities of the mold cooling system—a fundamental drawback of the brass baffle blade.

Eliminating Blow-By

Significant improvements in heat transfer from these hot-spots (and thus vastly improved overall mold cycle times) can be achieved if blow-by around baffle blades is eliminated (see Figure 2).

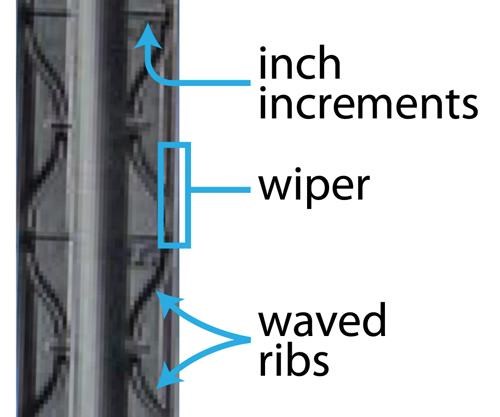

The new patented plastic baffle offers a tremendous advantage in that, being made of polypthalamide, it can include a patented wiper on each side of the blade. The wiper acts as a seal between the cooling channel and the edges of the plastic baffle blade, effectively eliminating the gap between the baffle blade and the coolant channel so that there is no blow-by. Coolant flows throughout all of the cooling channels, including up to and around the tip of each plastic baffle blade. The result is excellent thermal transfer out of the hot-spots, as the mold designers intended.

Additional Polypthalamide Advantages

Another set of advantages of using polypthalamide for baffle blades is that plastic baffle blades are molded rather than extruded. Thus, it is possible to include design features on the flat surfaces of the baffle blades. Waved ribs are designed onto the flat surfaces to act as chevrons or turbulence enhancers. Turbulent coolant flow transfers significantly more heat than laminar flow.

Finally, inch increments are also included on the flat surfaces of the plastic baffle blades, allowing mold builders to conveniently measure and snap the plastic baffle blades to the correct length during installation. This allows for much quicker installation than brass baffle blades, which must be measured, cut, ground and then installed (see Figure 3).

With multiple polypthalamide baffle blades, these many improvements over the traditional brass baffles quickly add up.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHow to Transition From a Cold to Hot Runner Mold

Reducing cycle time and costs while also freeing up your machines for other projects are advantages gained by using hot runners that no one can ignore. But where does one begin transitioning from cold to hot runners?

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreRead Next

Plate Positioning Perfected

Consider a positive precision plate device to overcome the risks and uncertainties inherent with springs and spring limiters.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More