OPEN MIND Technologies USA Inc.

1492 Highland Ave.

Unit 3

Needham, MA 02492 US

888-516-1232 | 339-225-4557

info.americas@openmind-tech.com

openmind-tech.com

About OPEN MIND Technologies USA Inc.

OPEN MIND is one of the world's leading developers of CAM solutions for machine & controller-independent programming. The company develops optimized CAD/CAM solutions that include many innovative features unavailable elsewhere, delivering significantly higher performance in programming & machining.

IS THIS YOUR COMPANY?

Video Gallery

Traditional Craftsmanship meets Modern Technology | 5-Axis Machining a Japanese Vase

Traditional craftsmanship meets modern technology! ✨ Experience the result of combining beauty and advanced machining ...

5-Axis Machining a Penholder | Write Your Story with hyperMILL

Write your story with 5-axis technology from hyperMILL ✒️. In this video, watch as a penholder is precisely machined using the ...

CNC machined Santa Claus | hyperMILL | HERMLE | Fraisa

Mini Santas in the Making! See how #hyperMILL teamed up with @HERMLE USA and @fraisausa machine aluminum mini ...

CNC machined Santa Claus | hyperMILL | HERMLE | Fraisa

How hyperMILL, HERMLE, and FRAISA Helped Santa Save Christmas! This holiday season, we joined forces with @HERMLE ...

As Seen On MoldMaking Technology

OPEN MIND Technologies USA Inc. Supplies the Following Products

- CAD (Computer Aided Design)

- CAM (Computer Aided Manufacturing)

- CNC Software

- NC Simulation and Verification Software

- Software for Additive Manufacturing—Job & File Management

- Software for Additive Manufacturing—Part Design

- Training and Consultancy Services—Additive Manufacturing

Trade Names Offered by OPEN MIND Technologies USA Inc.

Editorial, News, and Products

-

2024 Most-Viewed Products

A comprehensive dive into 2024’s most-viewed products, as revealed through MMT's analytics. This review highlights the most popular products, ranging from technologies, services, softwares and more from this past year.

-

Maximizing Machine Tool Potential With CAM Software

Identifying specific areas where CAM software can utilize machine capabilities to benefit the user and maximize milling machine potential.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

How to Optimize Mold Finishing

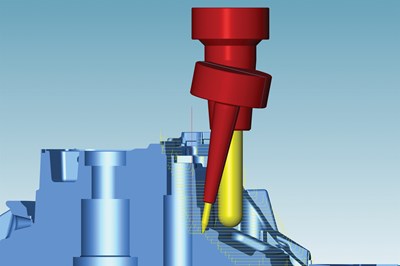

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

-

Innovative Technology for Your Mold Shop at IMTS 2024: Part 1

MoldMaking Technology highlights a variety of innovative applications featured this year at IMTS 2024. From software solutions to new machines and services, dive into this comprehensive guide to best equip your mold shop.

-

CAD/CAM Software Suite Enhances Intelligent Workflow for Tool, Moldmaking Projects

IMTS 2024: Open Mind Technologies showcases its hyperMILL CAD/CAM software with enhancements to its toolpath capabilities, overall functionality and more.

-

Innovating in an Ever-Changing Manufacturing Landscape

Innovation ensures your company remains adaptable to market changes and customer demands. These latest industry products/services are key to this objective.

-

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

-

2024 Software Suite Update Optimizes Tool Paths, Machining Capabilities

Open Mind brings updates to hyperMILL, with enhanced core toolpath strategies as well as new functionality for increased NC programming efficiency.

-

How to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

-

Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

-

Hybrid CAM Strategy Enables High-Quality, Efficient Mold Repair

As CAM technology requirements accelerate, and the market for additive/hybrid processes evolves, Open Mind highlights its hyperMILL for efficient repair or rework of molds.

-

Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

-

Software Environment Provides “CAD for CAM” Functionalities for Programmers

Two CAD function formats have been integrated into the hyperMILL environment to lessen the impact for users working in CAD or CAM.

-

MoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

-

Software Technology to Meet Moldmaking Challenges

Featured in this technology roundup are software solutions that can provide and improve design and manufacturing operations or data management practices during the manufacture of a mold.

-

Five-Axis Machine With Pallet Changer, 16k-Spindle, Versatile Control Makes More Accurate Molds Faster

The move from three- to five-axis machining with automation reduced setup times and improved surface finishes for this small but mighty Amish mold builder.

-

YCM Alliance Technical Center Grand Opening Highlights Customer-Centric Focus

The two-day event celebrated at the end of May brought in 300+ OEM and job shop customers, dealers and industry vendors for mold/die, general parts and high-speed machine demonstrations as well as industry expert presentations.

-

New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

-

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

-

CAD/CAM Software Generates Unique Additive Tool Paths for Mold Cooling Channels

The Open Mind hyperMILL Additive Manufacturing solution offers a variety of additive/hybrid functionalities, including toolpath strategies for designing intricate conformal cooling in a multi-axis machining setup.

-

Maintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

CAM Software Automation Recognizes, Remembers and Standardizes Complex Process Flows

For the everyday mold builder, Open Mind Technologies’ hyperMILL software with automation technology and a comprehensive Automation Center make it easier to define and adhere to manufacturing standards.

-

Modular, Flexible CAM Speeds Five-Axis Programming, Boosts Profitability for Moldmaker

P and C Tool improves mold quality, minimizes secondary processes, takes on new business opportunities and increases profitability with new integrated CAM software.

-

IMTS 2022 in a Flash

With this still being the month of IMTS, I thought I’d highlight some of the technology mold builders have expressed growing interest in and are actively investigating, and what was on the show floor.

-

IMTS 2022: From Precision Products & Professionals to Podcasts & Parties

Four years since the last IMTS and this 2022 event served up plenty of product line expansions, technology enhancements, candid conversations about business challenges and deep discussions about using technology and training to stay competitive.

-

Mold & Die Workshop Co-Hosted by Three Leading Companies

The Mold & Die workshop – hosted by Emuge-Franken USA, GROB Systems Inc. and Open Mind Technologies – will be held on July 20, 2022 at the Emuge Technology Center in West Boylston, Massachusetts.

-

Customized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

-

Repair, Repurpose Tooling in One Process with Hybrid/Additive Manufacturing

Open Mind Technologies offers an Additive Manufacturing capability option to hyperMILL to support 3D printing/additive processes, such as DED, WAAM and laser powder.

-

Metalworking Technologies Targeting Mold Builders

Inspection/measurement, cutting tools, design software, machining and automation equipment round out this technology roundup.

-

Three CAD/CAM Automation Advances

Feature-, attribute- and script-based CAD/CAM automation ease programming and skilled labor challenges.

-

Open Mind Technologies, Haimer Join Forces to Five-Axis Machine an Aluminum Panther

Open Mind provided its hyperMILL CAM software and Haimer its flour-flute cutter and a linear five-axis machining center for a 20-inch panther to be showcased by the Augsburger Panther hockey team.

-

CAM Software Optimizes Blow Mold Manufacturing

The hyperMILL software suite from OPEN MIND Technologies meets demanding blow mold requirements with automation processes, data import, efficient programming and NC code simulation.

-

CAD/CAM Software Augments Machining, Data Feedback, Convenience

The 2021.2 hyperMILL update from OPEN MIND Technologies enhances virtual machining, additive manufacturing, 3D finishing and hyperCAD-S features.

-

OPEN MIND Technologies Celebrates 25 Years of CAM Software Achievements

North American subsidiary reaches important milestone with hyperMILL CAD/CAM system, supporting Industry 4.0 initiatives and formidable consultation and services.

-

Technology Roundup: You'll Only See It Here!

MMT presents a compilation of digital-only new/proven product content. Cutting tools, machining, AM, software and inspection/measurement categories are showcased in this latest roundup.

-

Integrated CAM Solutions Improve CAD Data Access and Reuse

Integration of HOOPS Exchange, with OPEN MIND hyperMILL and hyperCAD-S tools maintain product manufacturing information and data integrity.

-

CAD/CAM Software Suite Enhancements Optimize Machine Tools and Molds

Latest hyperMILL 2021.1 CAD/CAM software suite updates offers several innovative features for efficient 3D, 5-axis and mill/turn machining

-

MoldMaking Technology's Top-Viewed October Content: Proper Cleaning, Efficiency and Troubleshooting

The MoldMaking Technology team has compiled this list of the top five items that you, our audience, have looked at the most. Check out these five items from October.

-

How to Select the Right Programming CAM Software for Directed Energy Deposition in Mold Repair and Modification

Selecting the right programming CAM software improves the use of directed energy deposition to repair and modify tooling.

-

Optimized Virtual Machining Enhances Mold Manufacturing

Virtual machining programs simulate computed tool paths as well as optimize machine tool capabilities and constraints, adding value to the computed tool paths.

-

Software Includes 3D, Five-Axis Machining Enhancements

Open Mind Technologies offers the advanced capabilities of hyperMill 2020.1 CAM software, including powerful 3D and five-axis machining enhancements for complex machining applications, including mold and die.

-

Software Enables Hybrid and Additive Manufacturing in One Process

OPEN MIND Technologies AG offers an additive manufacturing (AM) capability option in hyperMill CAM software to support 3D printing/additive processes that also provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

-

OPEN MIND Technologies Announces Additive Manufacturing Capability

Open Mind Technologies AG announces it offers an additive manufacturing capability option in hyperMill CAM software to support 3D printing/ additive processes.

-

Latest Software Version Offers Process Reliability

Open Mind Technologies AG introduces hyperMILL 2019.2, a new version of its comprehensive CAD/CAM software suite.

-

Noteworthy News: Congrats are in Order

From anniversaries to new hires to awards, MoldMaking Technology has the latest news in industry success stories.

-

Tech Trends: SOUTHTEC 2019 Sneak Peek

Attendees at SOUTHTEC 2019 will have the change to discover latest technologies and services to help them grow their businesses from Open Mind Technologies AG, Hexagon Production Software, Mazak Corporation and Rego-Fix.

-

OPEN MIND Celebrates 25 Years

Open Mind Technologies AG celebrates its 25th company anniversary this year.

-

CAM Software Speeds Programming and Optimizes Production

Precision Mold and Machining Services gains more control, accuracy and capacity, and better surface finish, with high-performance CAM software.

-

Amerimold 2019: Software Solutions for Moldmaking

Looking for software options that are developed for moldmaking? Amerimold had plenty in store for attendees and we bring you some highlights here.

-

2019 Technology Review: Software

MoldMaking Technology’s July 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including software.

-

Software Offers Range of Features and Enhancements

Open Mind Technologies will showcase the advanced capabilities of hyperMILL CAM software at Amerimold.

-

OPEN MIND, GROB Announce Five-Axis Machining Technology Seminar

OPEN MIND Technologies USA announces a joint Five-Axis Machining Technology Seminar with Grob Systems.

-

Five-Axis Workshop Offers Advanced Strategies, New Products and Live Demos

Three companies collaborate to give attendees new approaches for achieving speed and efficiency in rough and finish machining.

-

Reducing Risk to Implement CAM Software Successfully

Following a training and implementation period, new software technology can provide a strong return to the business and be key to long-term success.

-

CAM Software Accelerates Complete Machining

Standard parts supplier and moldmaker Knarr Group (Helmbrechts, Germany) leverages Open Mind's CAM software to maximize productivity.

-

Open Mind Announces Partnership with Okuma

Open Mind Technologies announced it has joined the Partners in THINC collaboration, founded by Okuma America Corporation.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

Open Mind to Feature Advanced CAM Software Capabilities at Amerimold

Open Mind Technologies AG highlights the capabilities of hyperMILL CAM software in Booth 123 at Amerimold.

-

CAD Software Automates Die-Sinking Electrode Manufacturing

Advanced CAD/CAM software with dedicated electrode design capabilities greatly reduces electrode design, modeling and manufacturing time.

-

Technology Tuesday: A Mix of Machining Products

Cruise through this week’s Technology Tuesday slideshow to see the latest products in machining.

-

Software Technology Is More Versatile, Efficient and Simplified

Software suppliers are working diligently to provide moldmakers with relevant but easy-to-use solutions that speed processes and lower costs.

-

Technology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

-

Improving Five-Axis Mold Finishing Operations

In an interview with MMT’s European Correspondent Barbara Schulz, Open Mind’s Peter Brambs explains how its five-axis tangent plane machining strategy can achieve time savings of up to 90 percent.

-

Technology Showcase: On Display at EMO 2017

EMO is a large, international metalworking tradeshow with thousands of exhibitors. Check out the slideshow to see what will be on display!

-

Technology Showcase: Machining, AM and Software

With Amerimold in our rear-view mirror for the time being, there are still several new products that have been released, or will be soon, to bring to MMT readers’ attention.

-

Technology Showcase: Case Studies

Here’s a Technology Showcase review of past case studies that you may have seen, but that may also be worth another look.

-

CAM Software/Machine Matchup Saves Time, Boosts Efficiency

A five-axis machining center and better CAM software helped this mold shop dramatically improve throughput and profitability.

-

Broadening CAM Applications for Barrel Cutters

This alternative cutting tool geometry, along with the right CAM software, can help moldmakers reduce finish-machining times.

-

Slideshow: EMO 2015

Here are some highlights from this year's event.

-

Barrel Cutters Going Mainstream?

This CAM developer is gearing up to release a new toolpath strategy for new standard-issue, circle-segment cutting tools that promise big gains in tool life, surface finish and cycle time.

-

CAM Automation is a Process, not a Goal

Automated NC programming requires a strategy to yield improved productivity, quality and consistency.

-

CAM Reduces Cycle Time when Machining Mold Bases

Feature recognition, CAM capabilities and machine controller interaction can reduce cycle time when machining mold bases.

-

Roughing Software

hyperMAXX

-

Four Key 5-Axis Programming Developments for Moldmakers

Recent advancements in CAM software offer new benefits while maintaining ease of use.

-

CAM Software Market Leaders Named by CIMdata

NC Market Analysis Report for 2010 Released.

-

The Benefits of a 4+1 Machining Process

The benefits of 4+1 machining can better the results of 5-axis machining: overall cutter life, cutting time and surface finish are improved.

-

Software Enhances Advancing Technologies

CAD/CAM’s improved features and new capabilities—combined with the latest in technologies like high speed and five-axis machining, new cutting tools and 3-D technologies—allow moldmakers to achieve the highest quality in the shortest time.

-

Maximizing Machine Tool Potential with CAM Software

Identifying specific items where CAM software can take advantage of machine capabilities to the benefit of the user and maximize exploitation of milling machine potential.

-

Automation and Moldmaking: Streamling Processes

Automation is coming into the forefront as moldmakers are on the hunt to automate with software and equipment to streamline processes for optimal productivity—and quality.

-

How to Achieve Economical Five-Axis Milling

Although moldmaking has not had great incentives to invest in five-axis technology like the aerospace industry, there are still many reasons for moldmakers to adopt five-axis machining, and there are a few interesting software functions that help to make five-axis programming economical.

-

Five-Axis Machining Is a Key Requirement for High-Precision Molds

Design and fabrication capabilities of advanced tool-cutting processes give toolmakers an edge in developing new business.

-

The Feature Technology Feature of CAD/CAM

CAM software should have forward looking features that allow you to work in a traditional programming approach and to step up into a more organized environment that includes storing process knowledge and corporate experiences.