Repair, Repurpose Tooling in One Process with Hybrid/Additive Manufacturing

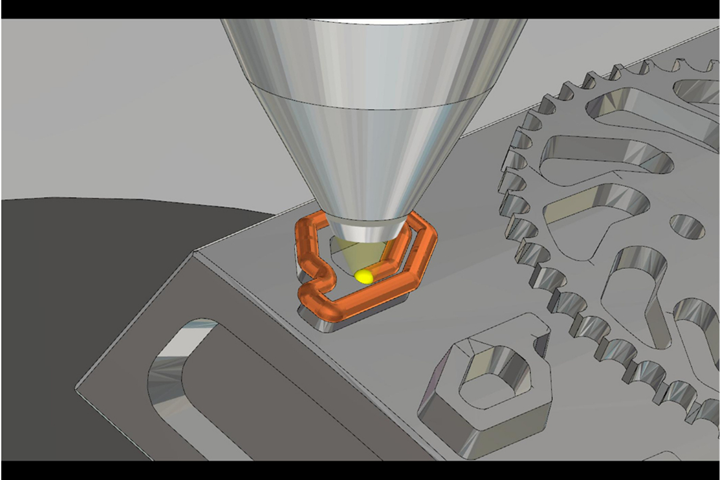

Open Mind Technologies offers an Additive Manufacturing capability option to hyperMILL to support 3D printing/additive processes, such as DED, WAAM and laser powder.

Photo Credit: Open Mind Technologies

Global CAD/CAM software solutions provider Open Mind Technologies offers an Additive Manufacturing capability option in its hyperMILL CAM software to support 3D printing/additive processes. This feature provides efficient hybrid processing with additive and subtractive processing, including material deposition, on one machine.

For highly complex five-axis simultaneous processing, Open Mind says hyperMILL Additive Manufacturing enables an array of flexible options for any directed energy deposition (DED) process — useful for repair or rework molds or tolling — such as wire arc additive manufacturing (WAAM), laser powder, laser hot-wire and electro-beam hot-wire and more.

hyperMILL programs the cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps, guarantee high reliability.

Key additive applications include repair of damaged components, cladding of additional surface skins or creation of new components from a substrate. This also creates novel options for combining different materials, such as when high-quality material layers need to be applied to the substrate.

Further, using powder bed fusion (PBF), hyperMILL is said to support the full potential of AM. The finishing of some functional surfaces and the removal of support structures can be performed using five-axis cutting processes. Also, due to the best fit capability built into the hyperMILL Virtual Machining strategy, it is now possible to virtually align the NC code to the real clamped part position, optimizing the 3D-printed part.

Related Content

-

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.