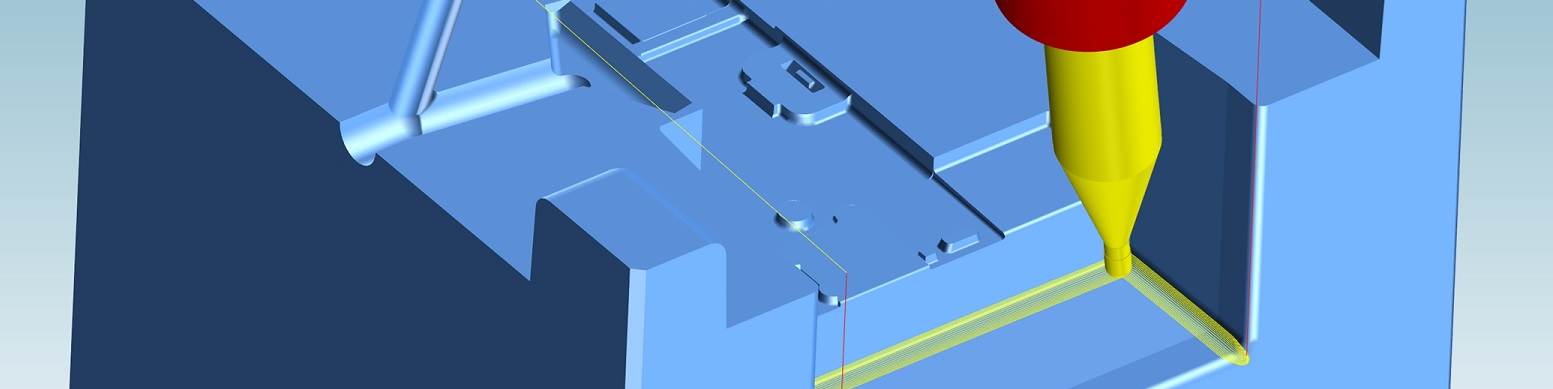

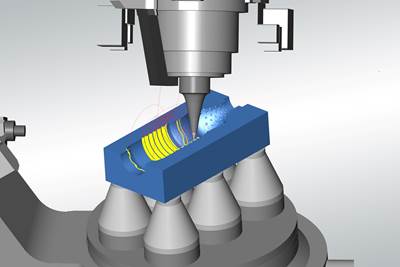

hyperMILL’s five-axis rest machining automatically creates 3+2 orientations for complete machining of tight, deep corners with minimal tool stick-out. Photo Credit: Open Mind Technologies Inc.

When a custom mold builder put a new five-axis milling machine into production, there was excitement about what the technology could bring to the table. Increased efficiency and accuracy, reduced setups and better access to part features are some of the well-known benefits of five-axis milling. However, it helps when you also have good CAM software to support it.

Founded 23 years ago, P and C Tool has 15 employees in its 10,000-square-foot Meadville, Pennsylvania facility, designing and manufacturing plastic injection molds and die-cast tooling. P and C also offers general contract machining, including emergency repairs, spare cores and cavities, jigs, fixtures, secondary operations and intricate aerospace parts. Its machining capabilities range from three- and five-axis CNC milling, wire and sinker EDM to CNC turning, surface and cylindrical grinding, and laser welding.

“P and C Tool was founded on the belief that there is a better way to build molds that provides quality tools with extremely short lead times. We combine high-tech CNC processes with skilled moldmaking that minimizes errors and maximizes machine time,” Ed Leech, P and C Tool’s director of engineering, says. With this in mind, the company continues to invest in the technology.

“We get into many single-cavity molds. As a result, most components are one-of-a-kind and custom-engineered, making profitability a challenge. We get one shot to make them right and it’s always in a hurry,” Leech says. To be profitable, the P and C team needs to keep spindles running to minimize idle time and meet tight delivery schedules.

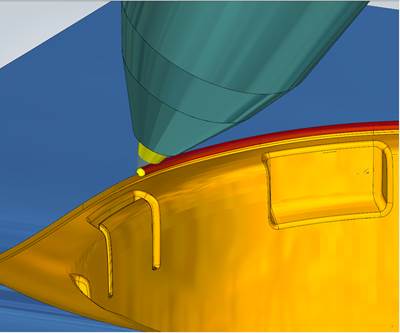

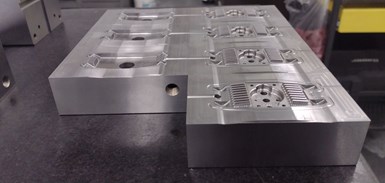

For this single-cavity die-cast tool with parting line injection, all shutoffs, gates, runners and interlocks were machined in one operation to 0.0001-inch tolerances. Complete programming time with hyperMILL for finishing was less than an hour. Photo Credit: P and C Tool

In 2019, P and C procured a Roeders five-axis milling machine. Since P and C specializes in custom-designed molds, most parts are uniquely engineered to close tolerances with seal surfaces as fine as 0.0001 of an inch. Early on, the team encountered problems keeping up with the Roeders’ capabilities due to the lack of throughput from the CAM software package that had been in use at P and C Tool for over 20 years.

“We had way too much spindle downtime while parts were being programmed, and we were unable to keep pace with production requirements. Again, because most everything we build is a one-off, each part needs a new program,” Leech explains.

Leech decided to investigate new software and came across a variety of hyperMILL CAM software videos on YouTube from Open Mind Technologies. He wanted to learn more about the CAM system.

“hyperMILL has tamed the complexity of five-axis machining so that even one-of-a-kind parts feel more like production work.”

CAM Answers Speed Requirements and More

Leech evaluated many CAM packages before finally pulling the trigger and acquiring hyperMILL. “But,” he says, “hyperMILL was so much faster than everything else I tried; it made the decision an obvious one. In addition, Open Mind’s demonstration team was the only CAM provider able to easily handle every off-script programming situation on the fly.” After an initial but quick ramp-up period, the results have exceeded the expectations of P and C Tool not only due to hyperMILL’s capabilities but also because of Open Mind’s support in making the transition as seamless as possible.

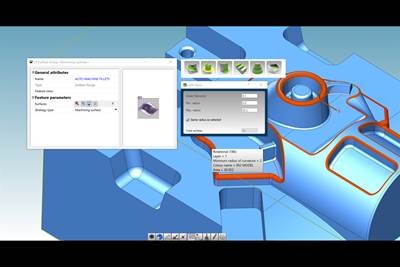

Open Mind Technologies’ hyperMILL software is a modular and flexible CAM solution for 2D, 3D and five-axis milling, mill turning and high-performance machining strategies with everything integrated into a single interface. This complete integration enables fast, easy five-axis programming using the latest operating concepts, reduced machining times and tool wear, improved process reliability and accurate, high-quality surface finishes.

Intelligent algorithms ensure automatic tool collision detection and avoidance with hyperMILL, and challenging features, such as high and steep walls, free-form surfaces and deep cavities, are automatically calculated and machined easily. Depending on the geometry and machine kinematics, users can choose between five-axis machining with a fixed tool angle, automatic indexing or true simultaneous machining.

One of the most significant aspects of the transition to hyperMILL was initially something Leech was quite apprehensive about. Leech had previously written all his postprocessors for P and C’s machines. However, he says that the post-processor from Open Mind’s hyperMILL is fully kinematically constrained and works perfectly. “Each time I need a tweak, I call support at Open Mind, and they send me a new post that I drop right in, which saves us weeks in postprocessor development,” Leech says.

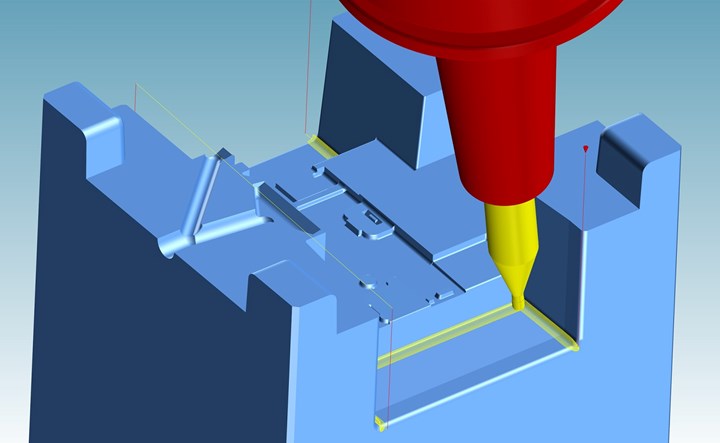

This 2+2 die-cast family tool is an example of an extremely detailed parting line with inside corners milled to 0.0078 inch. With a texture requirement on the molding surfaces, it is often harder to keep a toolpath off of those surfaces than it is to machine them. The ease of adding extension surfaces and stop surfaces with programmable offsets in hyperMILL let P and C Tool finish the shutoffs right up to the molding. Photo Credit: P and C Tool

Multiple CAM Benefits

P and C Tool has received many benefits since the switch to hyperMILL, all of which meet its speed and quality requirements while keeping the five-axis machine humming. Toolpath calculation and the postprocessing time are two to three times as fast as the company’s previous software.

Leech notes that besides being faster, hyperMILL enables for greater experimentation and trial of different creative methods because there is not a long wait for a complex toolpath to calculate. As a result, P and C can try new things and alternative solutions without bogging down the programming process. Additionally, toolpaths are not just calculated fast; they also run fast on the machine.

Leech says there is virtually no “air cutting” or tool breakage, even when stepping down from one end mill to smaller end mills in hardened steel. hyperMILL keeps track of the stock and keeps the tool in the cut.

In addition, multiple toolpaths can now be worked on simultaneously, allowing a programmer to quickly jump from one to the next while toolpaths are calculating in the background. “We can have many different parts open and work on them concurrently with one hyperMILL seat,” Leech says.

The postprocessor Open Mind built for P and C Tool is so safe and secure that Leech can run parts without worrying about crashes. He continuously puts new parts and programs into the machine. He leaves the milling operation unattended for up to 10 hours, so there is time for other projects, including programming the next part. As a result, Leech says, “hyperMILL has tamed the complexity of five-axis machining so that even one-of-a-kind parts feel more like production work.”

Versatility is another aspect of hyperMILL that P and C appreciates. Because the software is not tied to a strict, level-based stock progression, its team can mix and match stocks, geometries, parts, cover surfaces and guiding surfaces within a single program.

Taking advantage of hyperMILL’s trochoidal (high-performance roughing) toolpaths has been impressive. “With a single click of the high-performance tab, this toolpath strategy keeps the cutting tool buried deep in steel without breaking the end mill,” Leech says.

The tool library in hyperMILL is integral to the functionality and is fast and easy to use. It is upfront for adding new tools, reusing old tools, creating different toolholders, modifying tool lengths, setting up limitless materials, cutting parameters and machines. “But the best part is keeping an exact representation of every cutting tool in every machine for quick and easy retrieval and use,” Leech says.

Complete integration enables fast, easy five-axis programming using the latest operating concepts, reduced machining times and tool wear, improved process reliability and accurate, high-quality surface finishes.

Tremendous Toolpath Strategies

Leech believes that the five-axis rest machining toolpath alone is worth the price of admission. It performs five-axis pencil milling where the previous tool size and the surfaces to be machined are selected, and then hyperMILL generates a five-axis toolpath that flows around all corners. In comparison, the previous software’s toolpath was quirky, inefficient and generated spotty results.

Using other software, P and C Tool director of engineering Ed Leech saw a lot of air cutting when stepping down from one end mill to the next, especially on small, detailed areas and deep grooves like in this 4+4 family tool. The deep grooves in these cavities were roughed with a 0.039-inch toric end mill, and there was virtually no air-cutting and zero tool breakage, even though the previous tool was a 0.118-inch ball end mill. Photo Credit: P and C Tool

“hyperMILL's five-axis rest machining is super fast and smooth, and I rarely have to input any five-axis control over it manually. There is even a smooth overlap option that feathers the cut of a smaller tool into the larger tool, so there isn’t a mismatch,” Leech says. He points out that a 0.0001 of an inch mismatch between end mills can visually look much bigger than it is. The hyperMILL smooth overlap strategy helps to eliminate that problem.

hyperMILL has cut P and C Tool’s five-axis programming time in half or more, and the team can now keep up with the Roeders machine. “And it has also improved our toolpaths, so the cut time is faster,” Leech says.

Since it is a two-fold increase in speed, P and C has increased the type of milling work it can do and increased profitability, even enabling the company to take on higher cavitation work while still keeping up with single-cavity jobs. The quality of the work has also been improved, minimizing the need for additional EDM and grinding operations.

Single-cavity, custom molds can be challenging, as each component requires a new CAM program. However, hyperMILL eased this programming bottleneck for P and C Tool. Leech reports the shop has easily seen a 50% increase in throughput on five-axis work since its implementation.

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

How to Select the Right Programming CAM Software for Directed Energy Deposition in Mold Repair and Modification

Selecting the right programming CAM software improves the use of directed energy deposition to repair and modify tooling.

Read MoreCustomized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

Read MoreThree CAD/CAM Automation Advances

Feature-, attribute- and script-based CAD/CAM automation ease programming and skilled labor challenges.

Read More